Embroidery and sewing needle

Introduction

This article deals with needles used in machine embroidery. The choice of a suitable needle or not influences the result of an embroidery. The article defines the most important elements that define a needle, their main types and their use.

Let us first recall the principle of the functioning of stitching, which is the same for sewing machines and embroidery machines. The needle with the upper thread pierces the fabric. When the needle is down, the hook catches the upper thread and wraps it around the lower thread. This principle is illustrated in an animated figure down to the right. So the needle must (1) pierce the fabric (2) carry the thread and (3) let the upper thread be pulled by the hook to interlace it with the lower thread. This must be done without the thread blocking or floating too much. This is why it is important to have the right needle and to adjust the tension of the upper thread.

The needles must be adapted to the type and weight of the thread and the fabric to be embroidered. Embroidery needles are usually a little different from other types of sewing needles: the tip is slightly rounded (as universal sewing needles), the eye (eyelet, small hole for the thread) is slightly larger. However, for special tasks, sewing needles are used for embroidery, e.g. for embroidering on leather or jeans or for stitching either fine or heavy threads.

There are two needle manufacturers that dominate the market: Organ and Schmetz. Other relatively popular brands are Groz-Beckert and Klassé. Some yarn or machine manufacturers (e.g. Madeira) sell needles under their name, but do not manufacture them.

See also:

- Concepts of computerized embroidery

- Hooping and stabilizing in computerized embroidery

- Aiguille pour machines à broder et à coudre

Anatomy of a Sewing and Embroidery Needle

According to Wikipedia, based on Lydia Morgan's "needle machine know-how", needles have the following structure (from top to bottom):

- butt - the end on top of the needle

- shaft - to be clamped by the needle holder of the sewing or embroidery machine,

- shoulder or taper - where the stem tapers down to the shaft,

- shaft (or blade) - has a length suitable to driving the eye and the thread through the material and to the bobbin, defines the size (diameter) of the needle

- groove - cut into the front of the shaft to allow the thread to lie more closely to the needle as it passes through the fabric

- scarf - provides additional space for the hook or shuttle to pass closeby,

- eye - the hole, carries the thread,

- point - penetrates the material by separating the thread or by cutting a hole through a thread.

- tip - the end of the point.

- point groove - on the tip on some needles.

According to Wikipedia, the majority of sewing machine needles are made from various grades of hardened steel coated with nickel or chromium, although some special needles are coated with titanium nitride in addition to chromium. Titanium nitride is a gold-colored reflective ceramic material that reduces abrasion, allowing the needle to stay sharper and last much longer than other varieties. However, it can break as easily we believe.

Needle points

The needle points (and its tips) come in several variations and are combined with other properties such as eye length and width, needle thickness or groove. Terminology does not seem to standardized.

- Sharp point (sharp or very sharp) - pierces the threads

- Light ball point, slightly rounded, slightly pointed - typical sewing needle called universal needle, typcial embroider needle, or typical super universal needle (both sewing and embroidery)

- Medium ball point - does not pierce fine fabric threads

- Sharp cutting point - can cut thick materials.

Visually, there doesn't seem to be a big visual difference between various small/light ball tips, i.e. between a universal sewing needle and a standard embroidery needly. They have a somewhat blunt tip, but both should normally slide between the threads to preserve the tissue.

Organ uses the following typology for its tips:

- Slightly rounded point - Regular point - R

- Extra Lightweight Ball Point - Extra Small Ball Point - Q-ball

- Light ball point - Light ball stitch - J-ball/SES - Universal embroidery needle in the industrial system: DBxK5 SES

- Medium ball point - Medium ball point - B-ball/SUK.

- Large ball point - Large ball point - U-ball.

- Extra Large Ball Point - Extra Large Ball Point - Y-ball/SKF

- Slim point - Slim point - S.

- Slim sharp point - Slim sharp point - SPI.

- Cutting point - Cutting point leather left - LL (makes straight lines)

Organ manufactures a dozen of other cutting needles, the LR for example makes staggered cuts

Schmetz uses the following typology:

- Slightly rounded point - Slightly rounded point (universal needle, embroidery needle, metal needle)

- Acute round point - Acute round point (Microtex needle)

- Slightly rounded point with special taper - Slightly rounded point with special taper (quilting needle)

- Light ball point - Light ball point (embroidery needle)

- Medium ball point - Medium ball point (SUK) (stretch needle, jersey, jeans)

- Twist point - Twist point (LL) (leather needle)

Needle size

The length of a needle is standardized. The needle size refers to its diameter, which is measured in 1/100 mm (NM code). This size is often accompanied by a Singer size number, mostly obsolete in Europe, more popular in the United States.

Wikipedia distinguishes the following dimensions:

- L - total length of the needle,

- l1 - length from tip to eye (standardized)

- l - shaft length,

- d - stem diameter, needle size.

- D - shaft diameter (standardized)

We measured about 34mm between the tip and the beginning of the eye (l1). Since the eyes can have different lengths, a needle size 60 measures about 3.8 cm and a needle size 90, about 3.96 cm.

Let us look at typical sizes in the following table and their use and associated thread size

| metric NM

(mm/10) |

in mm | Singer/US size | typical fabrics with typical yarn (not metallic) | Typical threads | Schmetz color code |

|---|---|---|---|---|---|

| 130 | 1.3mm | 21 | Extra heavy fabrics | ||

| 125 | 1.25mm | 20 | black | ||

| 120 | 1.2mm | 19 | heavy jeans heavy fabric, artificial leather | threads 12 | brown |

| 110 | 1.1mm | 18 | threads 12 filaine | yellow | |

| 100 | 1mm | 16 | heavy fabrics, such as jeans, leather, canvas, etc. | threads 12, 30 | violet |

| 90 | 0.9mm | 14 | Medium weight fabrics (velvet, fine corduroy, linen, chiffon, knit, knitwear, fleece) | metallic, thread 30 | blue |

| 80 | 0.8mm | 12 | normal fabrics (cotton, light sweaters, linen,....) | 40 | orange |

| 75 | 0.75mm | 11 | 40 | pink | |

| 70 | 0.7mm | 10 | fine fabrics | 40 | green |

| 65 | 0.65mm | 9 | very fine fabrics (silk, chiffon, veil, ...) | 60 | white |

| 60 | 0.6mm | 8 | 60 | light blue | |

| 55 | 0.55mm | 7 | very fine fabrics | 60 and 75 | - |

Schmetz needles have after the ring that indicates its type, a second color ring that indicates size. Sometimes, color can be missing though.

The choice of the needle size is influenced by several factors: thread diameter, type of thread (normal or "difficult") and the type of tissue. According to Klassé (a needle manufacturer) the thread diameter should be about 40% of the needle size. The reason for this is the ratio between the needle size and the long groove size. The long groove on the front of the needle plays an essential role in the formation of each stitch and the thread must fit well into this groove. The width of the groove is 40% of the needle diameter. For example, for a needle size 90/14 (0.9 mm) the groove size is 0.36 mm and a thread 30 should fit. Note that thread size has nothing to do with width, it's a measure of 1000 metre hanks per kilo, meaning that less = fatter.

When the thread size fits perfectly into the long groove, it creates the optimal conditions for the best stitch, tension and trouble-free sewing. If the thread is too thick, it may become blocked and the following problems will occur: thread pull-out, thread breakage, missed stitches, uneven tension, etc. When the thread is much thinner than the groove, it creates a situation where an excessive amount of thread can form in the groove, which can reduce the size of the loop, skipped stitches, uneven tension, etc.

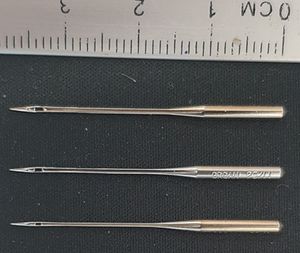

The following images shows various sizes of embroidery needles (H-E/standard): 60/8, 75/11, 90/14 and 110/18

-

Standard embroidery needles (top=90, middle=75, bottom=60)

-

Standard embroidery needles backside (top=90, middle=75, bottom=60)

-

90 and 110 gold-plated titanium embroidery needles (front/back)

Example.

The following design "tortures" the Lobster 2 Bold Italic font from InkStitch. Its design requires a minimum height, about 16mm. The correct use of this font is represented by the word "Stitch" outside the black patch. To test the "diameter" effect of the needle and thread, we will embroider the first two lines with a standard needle and thread and the next two with a thinner needle and a thinner thread.

The following table shows the needles, threads and densities used. By enlarging the picture, it is clear that small writings come out better with a needle 60 and a thread 60.

Eye size

Embroidery needles have a slightly larger eye compared to the standard needle. However, this difference is barely visible.

In some situations significantly wider eyes are required, e.g. metal, topstich or wool needles. Some threads do not pass properly through normal embroidery needles, especially "real" metallic and wider cotton or acrylic threads.

To embroider with large cotton or acrylic thread we recommend using TopStitch needles. The long and wide eyes of the Schmetz 100/16 Topstitch needle is clearly visible in the next image (top).

Among the manufacturers there are also slight differences in shape (as with all the rest of the needle).

Finally, there is a fundamental difference between the flat 130/705 needles (family and semi-professional) and the industrial round DBxK5 needles. In the following picture we see that a consumer/industrial Schmetz 90/14 H has a shorter eye than a small industrial/universal Organ 60/8 SES !

To remember:

- The eye of a normal needle grows a little with the size of the needle.

- There are two types of needles with a much longer and slightly wider eye: "Metallic" needles for thread containing metallic fragments and "TopStitch"/"Nachsticknadeln" needles for sewing decorative stitches and visible seams, but also for large and difficult embroidery threads.

- SES industrial needles have a longer eye than their consumer equivalent. So if you find instructions for a fabric or yarn on a site intended for professionals, please translate. For example, if Gunold suggests using a 90/14 SES needle for a large Cotton thread, you should not use a 90/14 H or H-E, but rather a "metallic" or topstitch needle, or a 110/18 titanium or jeans needle (but they make larger holes).

Needle types

In principle, there are only two types of systems adopted by needle manufacturers:

- The Groz-Beckert 130/705 system, also called HAx1 or 15x1 has a shaft with a flat side. This system is the most popular because it is much more stable. Practically all family machines plus semi-professional machines like our Brother PR1050X have adopted it.

- Industrial machines use the 287 WH system (also called DBxK5) which has a round cylinder for the rod.

Regarding the types of needles, needle manufacturers use according to Wikipedia (GER) a letter code that seems to be widespread. Some needles also adopt Schmetz color codes (one for needle type and one for its size), others have their own color code (check it out).

A needle is generally characterized by the following:

- The system (130/705/HAx1 or 287W/DBxK5)

- A name on the package you buy: For example "Universal needle", "Jeans", "Metallic",....

- The size, expressed in mm/10 and Singer system, e.g. 75/11

- The needle type, e.g. H-E

- The type of tip (most often implicit with the type of needle)

All the needles discussed in the table below have a groove, hence the H (hollow / Hohlnadel).

| Letter code for the needle type (system 130/705 H). | Schmetz color code for needle type | Scope of application | Type of tip | Eye | typical and (non-typical) sizes |

|---|---|---|---|---|---|

| H (SES at Organ) | colorless | Universal for sewing, also works for embroidery. Note the the Organ industrial SES needles have a longer eye (!) This is why it is recommended for thick thread by thread makers like Gunold. | slightly rounded ball point | normal | (55), 60, 65, 70, 75, 80, 85, 90, 100, 110, 120,

(125, 130, 140, 160) |

| H-E and H-EB | E = Embroidery | Universal for embroidery, there are titanium versions available | slightly rounded ball point | slightly wider than "normal", also true for the groove | (70), 75, (80), (85), 90, (100, 110) |

| H-ET | Gold embroidery | Embroidery, reinforced with titanium nitride (T), for hard tissues | as above | Slightly wider than "normal". | |

| H-J | J=Jeans | Jeans and artificial leather | Sharp, rigid tip (reinforced shank) | normal | (70), 90,100,110 |

| H-M | M=Microtex | Microfiber or other fine and/or dense materials. | sharp, pointed tip | normal | 60 - 110 |

| H-N | N= TopStitch | Ornaments, visible seams, useful for wide(heavy) wt 12 or wt 30 thread, in particular cotton, acrylic or woolen thread. | normal ballpoint slightly rounded | long (2mm) | (70), 80, 90, 100, (110) |

| H-MET | MET=Metallic | Metallized thread (fragments) | normal | long(2mm) and wider | 80,90,100 |

| H-Q | Q=Quilt | Quilting, step by step | Slightly rounded | normal | 75, 90 |

| H-S | S=Stretch | Stretch, T-shirts, underwear | medium rounded tip | normal | 65, 75, 90 |

| HAx1 SP | Super Stretch | Cotton knits, crepe, | medium rounded tip plus reinforced shank | eye wider than stretch | 65, 75, 90 |

| H-SUK | SUK = medium ball | Jersey, Knitwear, Lycra | medium rounded tip | normal | 70,75,80,90,100 |

| H-LL | LL= Leather Link | Thick leather and similar materials | Sharper, sharper tip | normal | 70, 75, 80, 90, 100, 120, 130 |

The names for the industrial DBxK5 system are different, including the tips. Organ distinguishes between standard stitch, medium ball stitch (SES) and large ball stitch (SUK) by their NY embroidery needles (round cone). Madeira distinguishes between R (pointed), RG (slightly rounded), FFG (rounded), FG (very rounded) and RG/San 1 needles.

| Letter code for needle type (system DBxK5 SES) | Scope of application | Type of tip | Eye | typical and (non-typical) sizes |

|---|---|---|---|---|

| DBxK5 SES | Silk, felt and other delicate materials up to heavy and rough ones, such as jeans and wool (depending on diameter) | small ballpoint, a universal Organ needle that's supposed to do it all. So the equivalent to the H-E but for the "round" heel system, but with a longer eye (!). | normal | 60 à 90 |

Let's go back to 130/705 flat shaft needles. The following image compares standard embroidery needles with jeans and stretch needles. We can see that the overall architecture is very similar. The only difference is a sharper tip and a stronger shaft that are difficult to see. The second image compares a stretch needle to an embroidery needle and we see that there is also little difference. The last image shows a Metallic needle by Bernina using a Schmetz coding.

-

Left: Needle 75/11 normal vs jeans. Right: Needles 90.

-

Left: Stretch needle, right embroidery needle (very similar).

-

Metallic needle 80/12 with color codes Schmetz (Bernina). Has a big eye.

Tips for choosing a needle

Most embroideries can be done with a normal embroidery needle (e.g. a 75/11 H-E) and a normal thread size 40. You can even use a so-called "universal" needle, but with slightly less good results for difficult threads. Some manufacturers such as Organ sell the same product in several forms (plastic tubs or small envelopes) and names (130/705 H vs. HAx1).

To help people to choose we give some examples and pictures of known brands. No preference, no comparisons were made, but we think it is wise to buy a quality product. We have had good experiences with Organ, Schmetz, Madeira, and Bernina. The brands of yarn or machine manufacturers are usually produced by a major brand and you also can buy these.

General advice

To obtain an optimal result, the yarn width, fabric type, and yarn type must be taken into account. Other criteria such as the type of embroidery can be added.

In machine embroidery, as a general rule, needles H-E or H between 70 and 90 are used. The Elna 8300 manual specifies that a 75/11 needle for fine fabrics and a 90/14 needle for medium to heavy fabrics should be used. The type of needle recommended by the Brother PR1050X manual is the specially made HAX 130 EBBR from Organ, available in sizes 65/9, 70/10, 75/11, 80/12 and 75/14. Schmetz System 130/705 H-E needles can be used as replacements. For a fast machine and "normal tissue", it is generally recommended to buy embroidery needles and not sewing universal needles.

Most typical needle for embroidery ("family" machines and semi-professional machines like the Brother PR).

- Organ: HAx1 H-E, size 75/11

- Schmetz: 130/705 H-E, code "red"

- For Brother PR machines: Organ HAx1 EBBR "flat shank"/"Blue tip", size 75/11

The most typical needle for industrial machines is a round needle, for example an Organ DBxK5 Round Schank, size 75/11.

The most typical needle for sewing is a 130/705 75/11 H (also called HAx1 universal needle). It is slightly different from an embroidery needle: slightly narrower eye and groove, more pointed ball. These universal needles (Organ or Schmetz H) can be used for embroidery, in particular for denser materials, but some threads such as rayon or fine metallic seem to pass less well.

If you work a lot with self-adhesive stabilizers or glue, you can try: Organ Anti-Glue 75

Yarn diameter (for a normal fabric)

- For a small diameter thread (e.g. Gunold POLY 60 or Madeira Radius 60) used for example for fine lettering (4-6 mm), use a 60/8 or 65/9 needle and increase the density by about 25% (7-8 stitches/mm for the border).

- For a medium large diameter thread (for example a Gunold POLY 30), a 90/14 needle should be used and the density should be reduced a little.

- For a large diameter thread (for example a Gunold Filaine 12 or Cotty 12), a 100/16 topstitch needle should be used and the density should be reduced a lot.

To embroider on special fabrics we choose to use specialized sewing needles, especially for embroidering on jeans or leather.

Embroidery on jeans

To embroider thick jeans or artificial leather, it is advisable to use a needle type H-J and at least one thickness between 90/14 and 110/18. These needles have a reinforced shaft and sharper point.

Examples:

- Organ Jeans, size 90/14.

- Schmetz Jeans, size 100/18.

- Alternative: Organ or Schmetz Titanium.

Leather

It seems that embroidery can tear fine leather and that stitching on thick leather is difficult. Hence the advice to embroider on medium thick leather, for example shoes, a strong jacket or a brief case. A leather needle is sharp and cutting. There are several variations. The most popular (H-LL) makes straight lines.

Embroidering on silk

- For silk, use a very fine round needle, e.g. H-S 70 or a very fine embroidery needle.

Embroidering on sweaters and other "stretch" materials

To embroider on stretch, sweaters, etc. normally use a needle with a rounder tip than an H-E embroidery needle.

Schmetz/Organ Super Stretch / HAx1 SP, size 75/11 or single stretch.

Finally, there seems to be little difference from a standard embroidery needle, so these also work. For some patterns on large sweaters, we also can choose the opposite: a sharp needle to preserve the geometry of the fabric, but it will cut through the wool.

Metallic threads

When embroidering with metallic thread, it is best to choose a needle with a longer and wider eye. These H-MET needles are sold under the name "Metallic", "Metal", "Metafil" etc. This said, if the thread does not contain too many fragments you can also use a normal embroidery needle 75/11 H-E or SES or maybe a little wider one (80/12 or 90/14).

Settings (to be adjusted for each type of metal needle):

- It is advisable to lower the tension a little, because the fragments can add brake.

- It is advisable to consider to work with less density, because most of these threads are size 30 (therefore thicker than the 40 threads typically used for embroidery.

- Do not exceed a speed of 600 stitches per minute.

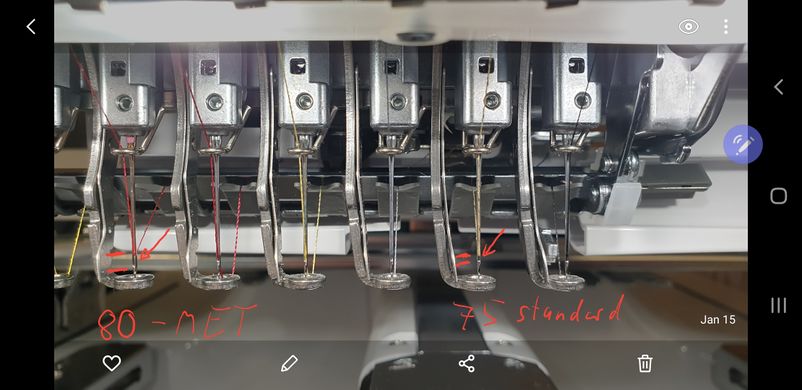

For thread type POLYSTAR by Gunold (about size 30), a H-MET needle size 80/12 (tested below) is recommended. According to Gunold, a universal needle (Organ 75/11 SES, not tested) could also be used, but we do not recommend it. Below is a test:

-

H-MET needle with wider eye for the #6 left (Gunold poly star 30 red) and standard H-E 75 for the #2 gold.

-

The golden lettering "RIDE" is a little irregular, because made with a "normal" embroidery needle (75 H-E)

-

The gold lettering "RIDE" is regular, because made with a 80 H-MET Metal needle. The word LIVE has been embroidered 2 times (just to see)

-

Monograms according to the rules: Solvable stabilizer in front, tear-off self-adhesive behind and metal needle.

To re-test: Results with lower density and results with a universal sewing needle.

Examples of needles:

- Schmetz Metallic needle, available in several widths, typically size 80 or 90 for 30 thread.

- Organ Metal, available in size 90/14 or 100/16.

- Bernina 130/705H Metafil (size 80/12), used in the tests above.

- Otherwise, another wide-opening needle may also do the trick.

Thread examples (to be confirmed)

- Fil-tec Glisten, with a 80/12 metal needle

- Gunold Polystar is size 30, with a 75/11, 80/12, or 75/11 SES / H-E metal needle.

- Gunold Glitter, a 80/12 metal needle (on round systems, a 75/11 SES "universal" needle seems to be enough)

- Gunold Mety 7/2, with a "metallic" needle 75/11 or 80/12, or a 75/11 H-E / SES

- Gunold Mety 5/2 is size 30, with a "metallic" needle 80/12 or 75/11 (a normal 75/11 SES for industrial machines). Slow down the speed to 500 or 400.

- Sulky/Gunold Metallic, with a metallic needle 80/12, 75/11 or a 75/11 H-E / SES

- Madeira Heavy Metal, with a metal needle 80/12 or 90/14

- Madeira Metallic Soft, with 80/12 or 90/14 metal needle

For almost all metallic threads, it is advisable to lower the speed a little and reduce the tension, especially if you are embroidering with a universal needle.

Heavy threads

Usually we recommend starting to learn embroidery with a polyester or viscose yarn (faux satin made from cotton) or a mixture of both. However, it is possible to create embroideries that look more like handmade embroideries with coton or acrylic wool. Some threads can be brushed to create a "fluffy" effect.

Cotton

- There exist cotton threads smooth enough for an embroidery machine. This type of thread can be brushed with a wire brush to give it a "furry" look.

Examples:

- Gunold Cotty 30 for use with a 80/12 or 75/11 H-E/SES needle.

- Gunold Cotty 12 for use with a 100/16 Topstitch needle (if missing, try a 110/18 H or a 90/11 H-E or metal). This rather thick thread makes it possible to simulate embroidery made by hand. Professional machines can use a SES 90/14.

Acrylic Wool

Examples:

- Gunold's Filaine 12 thread to be used with a 100/16 Topstich or "wool" needle (forget other types of needles!). Like Cotty, this thread can be "brushed".

Be careful with bobbin threads, e.g. Filaine and Cotty, Gunold suggests Bobby Syn 100 or or Bobby FIL 120 L. However, you should also check the instructions of your machine manufacturer. For example, Brother insists on using Bobby Thread 110 (with its cardboard) for the PR1050X or similar. Basically, all you need is your standard Polyester 60 (or thereabouts) thread.

Links

- Tout sur les aiguilles et Anatomie de l'aiguille (consulté le 1/4/2018)

- Sewing machine needle (Wikipedia)

- Nadel (Wikipedia, German)

- Nähmaschinennadel (Wikipedia, Allemand)

- Machine-Needle Know-How by Lydia Morgan, Threads Magazine #94 (2008), pp. 59-61

- Needle ABC (Les aiguilles de Schmetz, encore plus de variété, consulté 1/2021)

- Organ (chez Gunold, consulté 1/2021)

- Nähmaschinennadeln: Auf die richtige Nadel kommt es an! (consulté le 1/2021)