Embroider on socks

The problem

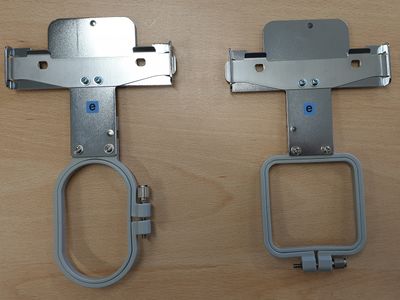

In order to embroider on a sock, one has to make sure that the machine only stitches on one side of the sock. This is a very easy task if your machine has a small free arm, like all professional and semi-professional machines do. Sometimes, small frames must be bought as an add-on, e.g. the "Compact Frame Set" with the "E" Frame holder for the PR1050X.

-

Small embroidery frames for the PRX1050X: Frame V (3.3 x 7.5 cm) and Frame 50

-

Stitching a sock with the small vertical 33x75mm Brother V frame

In this article we will present three methods that allow owners of consumer machines to stitch on socks. The first only requires safety pins, the 2nd "sock tool" method and the 3rd "sock frame" require a 3D printer, a laser cutter or similar. The "sock frame" method also requires measuring out a hoop and changing parameters of a 3D model.

Our most productive tool is the "sock frame", explained in the last chapter.

Embroider a sock using safety pins

The safety pin method is fairly easy to achieve, but it takes some time. The basic principle is to pin a roughly 5cm x 5cm area to the stabilizer for embroidery and pulling the tissue that would sit underneath away.

1) Hoop a strong stabilizer, preferably polyester. Tighten well (but without breaking the frame).

2) Optional: If your frame is thin or broken, it is advisable to fix the stabilizer with safety pins to the frame (c.f. the pictures below where you can see that the stabilizer has been attached at the top and bottom).

3) Attach the top of the sock like in the next picture below

- Start by fixing the 2 corners of the side you want to embroider, so the top/front of the sock.

- Then fix the 2 opposite corners as in the following image.

- In both cases, pull the sock slightly, but not too much, otherwise the embroidery will pull. Put the sock on your feet to see how much it would typically stretch....

4) Pull the surface to be embroidered in three directions and then fix the tissue with safety pins as in the pictures below.

- It is important that the fabric to be embroidered is flat and that nothing gets stuck underneath (otherwise you won't be able to fit in your sock). Pinch the fabric about halfway between the bottom (c.f. point 3) and the top and pull it out well !

- To attach this pulled embroidery surface you need at least three pins: One at the bottom, one on the left and one on the right. The following picture already shows a pin on the left and on the right. On the left you can see the head of a pin that was used in step 3.

Below is a decent hooping result (our second attempt). We can see the surface to be embroidered. Underneath there is only the stabilizer.

5) Stitch ....

-

Alien in progress

-

DNA in progress

Advice:

- Obviously it is difficult to do precision embroidery. So you have to either work with airy designs or overlap embroidery surfaces to avoid gaps. Also avoid too tight satin stitches (2mm is a minimum) or small fill areas. E.g. watch our for eyes.

- Do not exceed a total surface of 5x4cm for an adult sock.

Results:

-

DNA embroidered on an elastic cotton sock

-

Alien embroidered on an elastic cotton sock

Embroider with the sock tool

The sock tool (in the frame sock hoop) does basically the same thing as the safety pin method and we got the idea for this tool from looking the pictures above. It clears a 50 x 50 mm space for embroidery. Instead of pulling various bits of the sock with safety pins, you wrap the sock around the tool so that there is a small 40 to 60mm stitcheable surface, as we shall explain.

Warning: This tool may damage your embroidery machine if not used correctly. Do not use it if you do not feel confident with hoop selection and design positioning. It's like driving a car on a small mountain road: you need to understand where to position the car and where the boundaries are ....

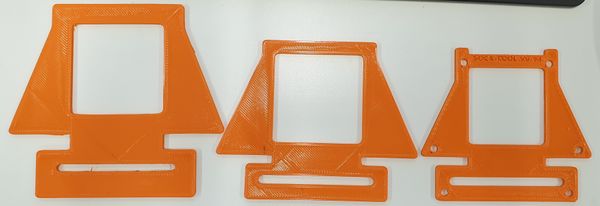

Choose your sock tool

Firstly you need a sock tool. You can

- 3D print i or laser cut it (faster)

- order it from an online printing/lasering service

- or down just download one of the L,M,S sizes ready for printing or cutting.

In order to produce the right custom size for your needs, install OpenScad (download) (a free CAD programming tool). Once installed:

- Download the sock tool or use the composer interface on thingiverse if it works (as of Jan 5 2021 it seems to be broken).

In OpenScad:

- Open the sock-tool-v*.scad file. Best, take the latest version from UniGE or Arbores Tech

- Hit F5 to display the model

- Open the Customizer panel (Menu View -> Untick "Hide Customizer").

- Configure your version of the sock tool. The default values work with medium man sized socks (EU size 41 / US size 8)

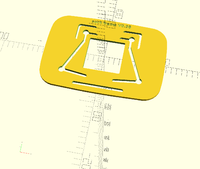

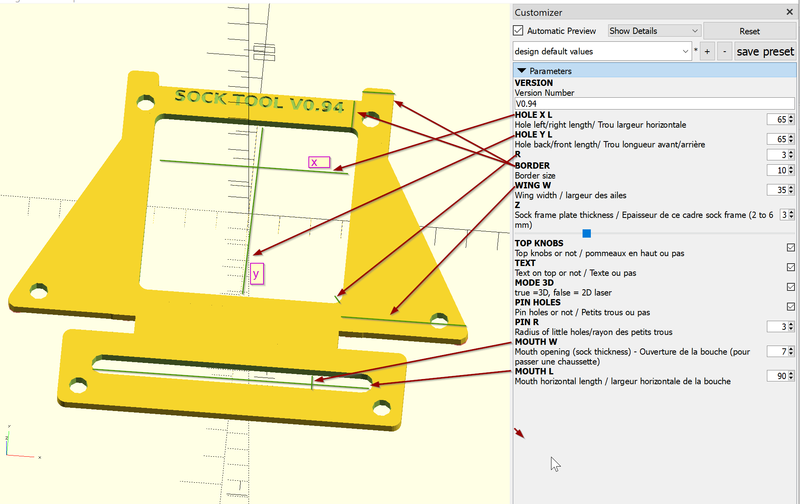

As of version 0.94, the configuration interface looks like in the following screen capture. The most important parameters concern the size of the hole, the size of the border, and the length of the "wings".

There are various minor options, e.g. add some writing on top or create holes

Before you print, laser or buy a sock tool we suggest printing out a paper version, then evaluating if your socks fit onto your configuration. To print out a paper version, untick "MODE 3D" in the composer panel. Then hit F6 and export the file as SVG. The SVG version then can be used with a laser cutter. You also can just print out the medium version from the sock tool directory.

For 3D printing, keep "MODE 3D" checked, then hit F6, then export as STL. This object can be printed easily. I print it with fat 0.56 layers and a 0.7mm nozzle. Print time is between 45 and 90 minutes, depending on its size and speed settings. With smaller layer size, you can print faster and the print should take about 2 to 3 hours.

Embroidery design for socks

We suggest to avoid dense small items, e.g. leave eyes out or make them bigger.

You must adapt your design to the size of the hole. We suggest to respect a safety margin of at least 1.25cm on each side, that is length = hole size - 2.5cm.

- For a 70 x 70 tool (medium socks), do not exceed 45 x 45mm

- For a 60 x 60 tool (smaller socks), keep it down to 35 x 35 mm

For additional safety we also encourage stitching some kind of fixing line first. Most embroidery machines also allow to tack down the tissue. Make sure that this line stitches is close to your design (in principle this distance can be set somewhere in the settings, I use 2mm).

Use of the sock tool

Step 1: Attaching the sock to the sock tool

As describe above, firstly select the right sock tool size, e.g. the default settings probably generate a tool with a 7cmx7cm hole, a 1cm border and 3.7cm wings that fits medium sock size well.

a) Insert the sock and attach the corners

- Push the upper end of the sock through the "mouth"

- Attach the back side of the sock to the bottom and the front side to the top as seen in the next picture

- Start with either the bottom or side and then do the rest.

b) Pull the tissue underneath over the wings

- Turn the object around to the back and stretch the tissue that sits underneath the area you plan to stitch.

Avoid damaging the sock ! I.e. pull laterally and then wrap around the rather sharp corner

c) Stretch the sock downwards

- Once attached to the sides, gently pull the sock down, i.e. through the hole

d) Adjust

- Make adjustments until the surface to embroider looks good

e) Flatten

- Pull additional tissue through the sock hole, i.e. try to make the whole package as flat as possible.

Step 2 Prepare the embroidery hoop

- Insert auto-adhesive stabilizer sticky side up into a hoop that is bigger than the sock tool. Alternatively use some cut away stabilizer and washable glue.

- Remove the protection of the stabilizer

- Put the sock tool as much in the center of the hoop as you can, as seen in the next picture.

- (Option) secure with 2 safety pins. I never do that since I feel confident :)

Step 3 Position the design in the embroidery interface

- Insert the hoop into the machine and make sure that machine is aware of the hoop size

- Load the design into the machine

- Verify hoop size again and change if necessary (some machines do not behave)

- Position the design so that its center is the center of the hole.

- Make sure that your machine stitches the design around the center.

- Verify if your design is well positioned by any offered means, e.g. have the machine outline the design area by moving its foot. Adjust if necessary, i.e. move the design in the control screen.

Step 4 Stitch

- If you are confident of your positioning, stitch a tack down rectangle. Before doing so make sure that the line is close to the design (that can be defined in the settings). Else do not do that, since your foot or needle may run into a wall.

Step 5 Remove the sock

Once stitched gently remove the sock, patch the hole and start over.

Done !

Embroider with the sock frame

Using the sock frame (sock hoop) is the most productive option, but it requires configuring an add-on frame that fits into one of your medium or large sized embroidery frames as shown in the next picture. See also, a short video.

Getting a sock frame

The sock frame is an add-on for ordinary embroidery frames, i.e. it replaces the inner frame under the condition that frame is attached to the machine with the outer frame. If this is not the case it is more difficult to get the sock frame working. For example the standard frames of the Brother PR1050X are carried by the inner frame (but then this machine does have a nice sock frame).

The sock frame design is available as *.scad file from at least the following locations:

Firstly, check if there already is version suitable for your frame, else you will have to measure and produce your own, either by 3D printing, laser cutting or by buying it via an online service.

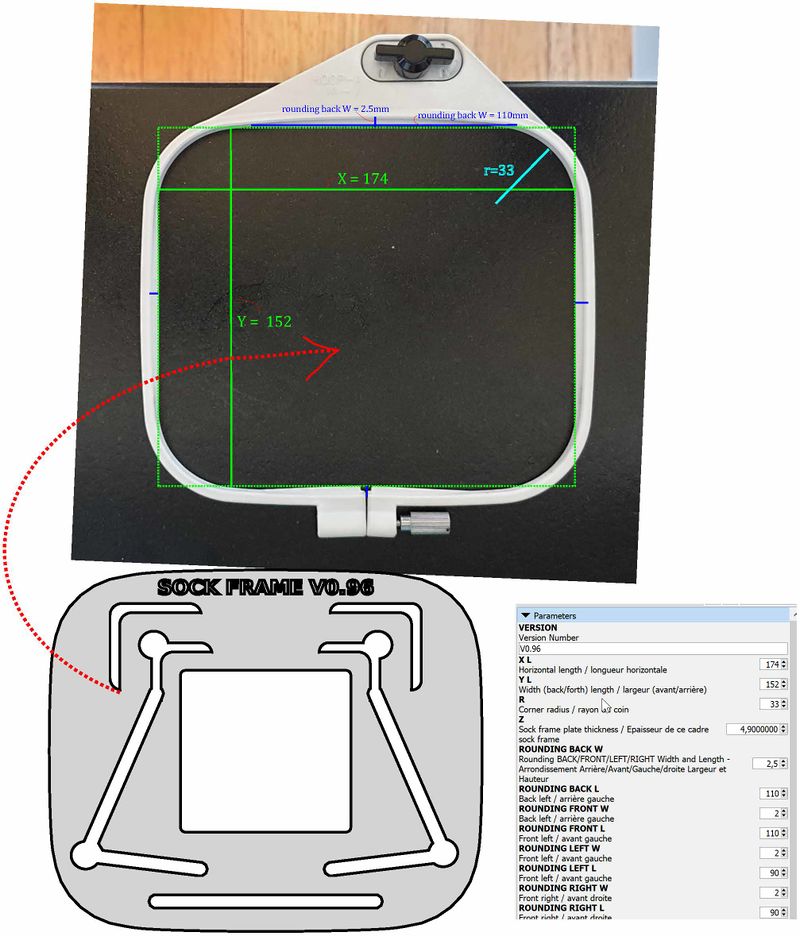

Second, make some measurements. You will need the following crucial measures as illustrated in the following picture:

- length

- width

- roundings ("bombings")

- radius of the corner

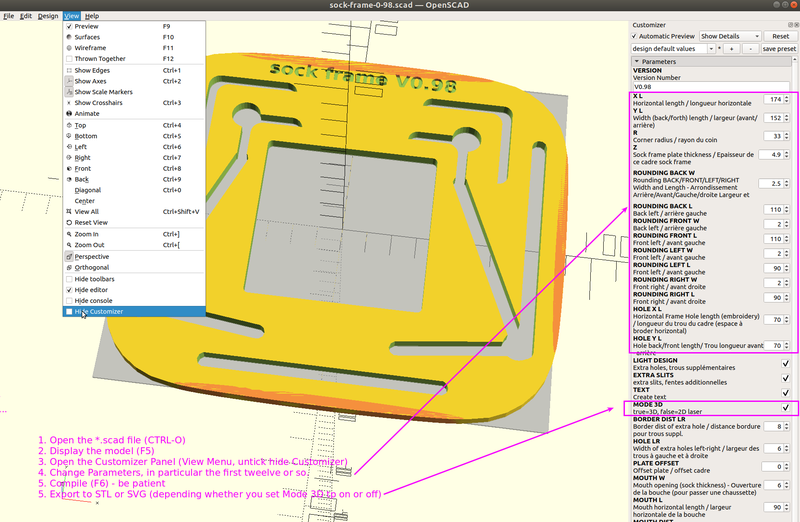

Configure your frame and export the model:

- Open the sock-tool-v*.scad file in OpenSCAD.

- Hit F5 to display the model

- Open the Customizer panel (Menu View -> Untick "Hide Customizer").

- Configure your version of the sock frame. The default values work with medium man sized socks (EU size 41 / US size 8)

The following screenshot shows OpenSCAD with the open customizer window. Of course, if you have some programming skill you may prefer editing the code using the built-in or an external editor.

Once you are happy with your changes, you should produced a paper version before you print it.

- Untick MODE 3D.

- Hit F6 (wait)

- Save your configuration as preset (or write down your options)

- Export as SVG, print, cut out and see if it fits your frame. Pay attention to the corners, they could be too sharp.

If the paper version is OK, you can laser cut the SVG (add a 1mm border first, remove the fills, and make the cut lines smaller).

Else, check MODE 3D, F6, and export as STL for 3D printing.

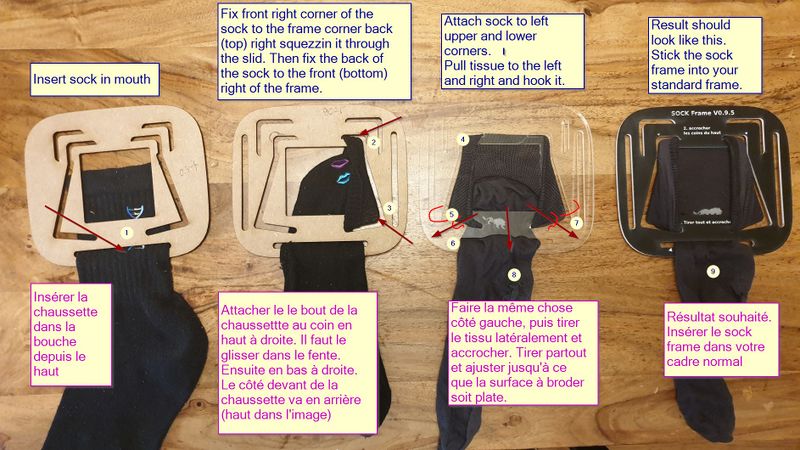

Attaching a sock to the sock frame

The sock frame allows clearing a small space (between 5x5cm and 7x7cm) for stitching on the sock.

Steps:

- Push the upper end (top) of the sock through the "mouth" (1)

- Attach the back side of the sock to the bottom and the front side to the top as seen in the next picture (2-3-4-5)

- Start with either the bottom or the side, then do the rest.

- Pull the tissue underneath over the "wings" (6-7)

- Pull down (8)

- Make adjustments until you are happy with the tension and alignment of the surface to stitch.

Example (version 0.98):

-

Sock frame - version 0.98 prototype ultra-draft print (front)

-

Sock frame - version 0.98 prototype ultra-draft print (back)

Stitching with a sock frame

Now, this is the moment where you got to be careful. Basically, if your machine can tell you what surface area it will stitch, you are safe. Else, you are not !

- Insert the hoop into the machine and make sure that machine is aware of the hoop size

- Load the design into the machine

- Verify hoop size again and change if necessary (some machines do not behave)

- Position the design on the control screen so that its center is the center of the hole.

- Make sure that your machine stitches the design around the center or if it does not, adjust your positioning

- Verify if your design is well positioned by any offered means, e.g. have the machine outline the design by moving the foot. Adjust the position if necessary, i.e. move the design again in the control screen.

Downloads

Sock tool

- Sock tool directory (take the latest *.scad file)

- Thing 4711120 on Thingiverse

Sock frame

- Sock frame directory (take the latest *.scad file)

- Thing 4711086 On Thingiverse

Buy a sock tool or a sock frame

It is possible to use an online service to create your custom tool. An object made with laser cutting will cost less. To be clear: At least for now I am not putting up anything for sale. You upload your configured design to an online service of your choice and then pay for printing and shipping.

- Produce a 2D version (uncheck "3D Mode" in the "Customizer" panel)

- F6 and then export to SVG and check the file. It is useful to add a border (by default there is none) and empty the fill.

Example: sculpteo asks about 15 Euros for the next two sock tools:

I put a few files on Sculpteo, so you can directly buy them (I don't get anything). But reconsider and rather order a lasercut version. I cannot create links for these.

Raw:

- https://www.sculpteo.com/fr/print/sock-tool-095-x-small-55x55-simple-3/eF6P5m4F

- https://www.sculpteo.com/fr/print/sock-tool-095-small-60x60-simple-5/nNAWPeda

- https://www.sculpteo.com/fr/print/sock-tool-095-medium-70x70-simple-1/jAe6Lbs2

With some text: