Felix 1.0 3D printer

<pageby comments="false"/>

Introduction

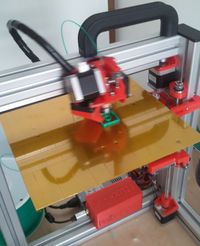

Felix is a low cost 3D Printer, available as kit. It is the IMHO the most practical printer for schools, since it can be easily carried around and since it has a very stable frame.

In the future, this page will be split into several pages as contents grow. I got the assembled Felix today and just started playing a bit

- Daniel K. Schneider 19:06, 18 June 2012 (CEST).

Where and what

Getting it

The kit is sold through the felixprinter web site. It costs about 900 € (excluding VAT and shipping costs).

Software

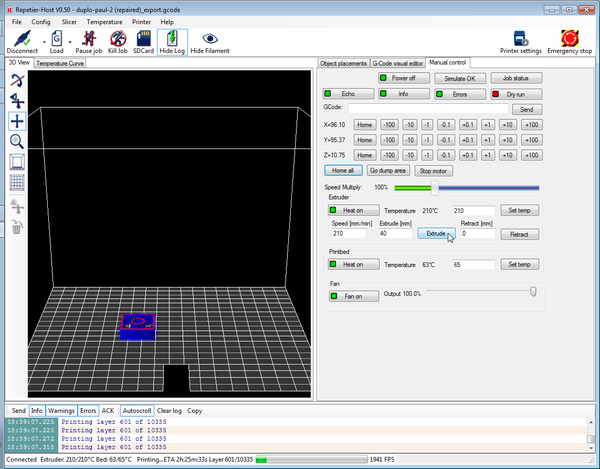

- The open source Repetier-Host program will pilot the printer through a USB host cable. It will interface with three different slicer programs, i.e. skeinforge SFACT (a skeinforge modification) or Slic3r. A distribution with a pre-configured SFACT/skeinforge and slic3r is available from Felix (for registered forum users)

Materials

- 1.75mm PLA rolls

- ABS can be printed, but I did not try.

Support

- Felix forums (Registration required for posting and download)

First impressions

After unpacking, installing and configuring the controlling/slicer software (about 15 minutes), I was able to print a Duplo piece with a bicycle glyph on top without changing any default settings. That is quite remarkable, although I do have experience with two other printers, the RapMan (bought 2 1/2 years ago) and the fabbster (bought recently).

The second print (also using default settings) was an easy-to-print model on a difficult to print Lego block. Also came out rather nicely.

The third print (again using default settings) was 3D character of a serious game made by a co-worker and that I put on top of a DUPLO block. The model wasn't specifically made for a 3D printer (had some serious overhangs), but came out fairly ok. The horizontal overhangs did not print very well, but that is expected without using any support structures...

The 4th to 6th print was the same DUPLO with some text on top. I changed the SFACT/Skeinforge Speed settings, i.e. put scalers to 1.15 (more flow). Note that SFACT doesn't work like the normal Skeinforge !

Impressions after a few weeks

The printer still works fine. On the mechanical side:

- It is really important to calibrate the platform. It must be even and be close to the nozzle.

- Regular, safe filament intake is very important for unsupervised printing. I am very happy with my intellectually easy chemistry stand solution...

- Extruder arm tension must be right. Before printing, test extrusion should show constant flow.

On the software side:

- I do have issues with SFACT (the default slicer for the more ambitious). For instance I don't know how to print bridges over pillars, e.g. the kind you get in larger DUPLO pieces. Filament will bond laterally and to the nibbles underneath and create a messy first layer. Printing with a higher layer solution helps, but then the overall quality won't be as good. I do have the same issue with the fabbster.

- Other types of objects slice and print very well.

Student designed example

I decided to teach a optional digital design and fabrication class every 2 years. Last edition was in fall 2011 and students could do a 3D printing project, other options were embroidery, vinyl cutting and music. One student did a Reuleaux triangle kit (see Wikipedia). I had to adapt the design somewhat. The triangle can't be printed and the Wankel piece floor led to lateral bonding, so I punched some holes in it ...

Lego-compatible castle

Larger structures can print fine:

- if the the platform is calibrated as it should: nozzle must be close in all locations

- if the first layer is printed very slowly (that is actually true for most objects, but if you have to restart for a small object it doesn't matter much ....)

- if the filament spooler is reliable and the filament roll has no tangles. This happened to me in the middle of the print below, I had to cut the filament since it somehow got stuck underneath. Fortunately I was there when the roll started to put up resistance. Otherwise, the Felix can IMHO be trusted for longer unsupervised printing. I went away for three hours when I printed the castle below...

- Download lugo stronghold from thingiverse

- (low quality) You Tube video showing the printing process around 2/3 of the print time

Assembly

Procedure

Assembly of the current model requires some soldering skills as in most other 3D printing kits. Assembling the structure seems to be very easy. Assembly seems to take about 5 to 12 hours depending on your DYI skills. The next version will be easier to assemble according to Guillaume Feliksdal, its creator.

Since we didn't do any assembly, we can't provide any help. The assembly manual seems to be detailed enough.

Fully assembled

For now, Felix doesn't officially offer fully assembled models, but may do so in the future. However, I exceptionally managed to order a fully assembled and tested version. The printer fell off a truck or something and arrived broken. Of course, a fully assembled printer is more fragile, but it was IMHO well packaged in a sturdy box and the Post Office admitted mishandling.

The repaired version arrived via UPS and with different (custom foam) packaging and it worked like a charm out of the box. No calibration was needed, only the software had to installed and configured.

Tips

Heating up and printing

(1a) Prepare the printer and the model

- The Felix is driven by Repetier Host software that must be configured according to instructions. Connect the USB cable.

- Ensure that the platform is calibrated right (see also below). The nozzle must be very close to the platform in all areas, but not touch !

- Make sure that there is no grease on the platform. Clean with alcohol or some other appropriate liquid

- Heat the platform (since this takes most time)

- Slice your model next (leave the printer cold if the model is very complex, else also heat the hot end)

- Then heat hot end and also turn the fan on (100%). Do not forget this, both a hot bed and the cooling fan is needed or the filament won't stick.

(1b) Check filament extrusion

- Before printing, lower the z-axis by 20, then extrude some 60mm of filament at 150mm/s. Repeat with 200mm or so. If extrusion isn't a nice constant flow, then you could reverse extrude at high speed (500 mm/s), cut the filament, reinsert and restart (extrude again at least 300mm). .

- If filament still doesn't flow consistently, try adjusting the extruder arm: You either must tighten or loosen and you will have to figure this out by trial and error. In my case, my first prints used too low tension, so start by tightening maybe.

- Make sure that no filament hangs around the nozzle, it could mess up your first layer.

- You also may try changing the temperature, warmer is easier flow, however print quality will be lower. I also found that it helps to extrude at much higher temperatures (240) before printing, and then going back to normal.

- Worst case scenario is a dust on the filament, some clogging inside or both. The nozzle really should have clean inside walls. Also, there may be some hardened piece of plastic that just sits before the nozzle (e.g. in the 2mm "space"). As we said, extruding before printing can help unclog, else see the extruder clogging issue below ...

(2) Print

- Then print. Again, make sure that filament intake works well. Using a good filament holder is essential for non or semi-supervised printing.

- An IMHO good (but expensive) solution I came up with can be found here, i.e. I use a retort stand.

(3) After printing

- After printing, immediately remove the filament with reverse extrusion or else start a new print with an object that you sliced during the print. Filament that will stay in a hot extruder may clog later. At least, don't keep the printer hot, i.e. make sure that in Repetier Host the printer is configured "heat off" after printing.

- Reverse extrude a high speed (300). You may have to pull the filament a bit. Also make sure to remove broken piece(s) that could remain between the plastic intake and the hot end. Such pieces actually may get stuck in the upper part of the extruder (it happened to me once and that is how I learned how to disassemble the hot end). You may as well check the x-axis pulley and belt once in a while. Filament also can be stuck there.

- Let the platform cool down a bit before removing pieces. They will come off easily and won't be warped. Tearing away is tempting (and I do it often), but there is some punishment for that, e.g. Kapton tape needs to be replaced more quickly.

Changing filament while it prints

There are two methods:

(1) Pause the printer with the repetier host software

- Pause (and wait until it stops)

- Them move the nozzle up and away (anywhere into an empty space)

- Retract and reinsert as usual

- Make sure to extract quite a lot of plastic. I'd say at least 200mm in order to have the right preasure. If the nozzle starts in some uneven space, then filament may not come out and clog.

- Unpause: The extruder should restart exactly where it left. There is no need for you to reposition.

(2) Exchange while it prints

This can be done fairly easily unless you are printing an area where the extruder retracts a lot (in that case you certainly should try the first solution).

So, if you see that you are near the end of your roll or that the plastic gets stuck in the roll and needs to be cut (crossovers, happended to me) :

- Make a clear orthogonal cut for both (filament in the extruder) and filament on the roll. In other words the ends must be flat, so that the new can push down the old one.

- Then just insert the new end after the one that will be spent

- Gently help by pushing down gently (!). Make sure not inhibit retractions of the extruder....

Btw. These methods can be used to print objects with more colors, e.g. a yellow duck on top of a green hill.

Adjustment of the platform and the extruder arm

- Platform adjustment

- Make very sure that the nozzle is close to the platform in any location (you can test this by inserting 2-3 sheets of paper underneath the nozzle after raising the nozzle by 0.1mm before moving it around). In no area should the nozzle run into the platform. This is absolutely mission critical. If your platform is horizontal, then the nozzle should almost touch the platform in its home position. Almost really means almost (i.e. "1 sheet of paper" distance and no more)

- Use the three screws: tighten = lower, loosen = raise.

Click on the following thumbnails (twice) to see what happens if the nozzle distance is either bad or ok. Prints shows the start of a Lego castle (to the left a floor design I later modified because larger rectangles (to the right) print a bit faster and are less prone to errors).

- Platform surface

- Make sure that there is no grease on the platform (e.g. from finger prints), e.g. use alcohol for cleaning. Someone (ref?) also reported that you could buy some glass, e.g. a picture frame in a DYI store and clip it to the platform. Adherence should be better, but heating will be slower.

- Also, never forget to fully heat the platform. PLA will not stick well to a colder platform. ABS is even worse though maybe printing it very hotly (260 degrees) could help (not tested yet).

- Printing with ABS. One solution might be to add another surface on top (and adjust z-height of course). E.g. you could use some acrylic sheet. I'll try that with a spare rapman print bed I still own. For small objects no heating would be required. For larger object more heat than 65 degrees is needed.

- Extruder arm

- When you extrude filament, plastic should come out consistently. If it doesn't, the nozzle may be dirty inside or the extruder arm tension may be too low or too high. Of course, also check the temperature.

- Adjust the little M4 bolt (if filament is inside, hold the screw with pliers, else it will turn). Rather try make it more tense for starters ...

Preventing and removing clogging of the extruder

After printing, immediately retract the filament. If you can't (e.g. when you print unsupervised) make sure that the control software let's the printer cool down. IMHO, leaving the heat on with filament inside will have it turn to glass after a while.

If the extruder is clogged, you can try the following in this order:

(1) Light clogging

- Heat up (maybe more than usual), then extrude filament. Help it by gently pushing down. If this does not work, then try the next item.

- Reverse extrude, then wait some time. There may be a some bits of filament just before the nozzle and that can be pushed down when warmer. Extrude filament at about 150mm and gently help with pushing. If this doesn't help, see the next item.

- Use a very fine long needle that you can insert from the bottom though the nozzle. Textile needles won't do. You will have to buy ones that are longer and finer. I got "SERIN acupuncture" needles. Move the platform down (at least 100mm) and do this while the nozzle is hot.

(2) Heavy clogging

There can be two causes IMHO:

- Dirt clogs inside the hot end

- There could be just some stuck broken filament, so that the new one can't push it down properly

Procedure for cleaning the extruder:

- Remove the hot-end. Unscrew the M8 bolt and slide it out. You may have to wiggle and search for the right position. Be careful because the wires attached to the nozzle can break.

- Now disassemble the upper part. As suggested indirectly in picture below, use pliers to hold the beige part and turn the aluminum part with other pliers (or better) with a hex key that fits.

Now you should see what is wrong. It may be just some filament that sticks out from the nozzle and that you can remove with pliers after heating the nozzle.

- You may have to remove the beige isolation (peek) part from the nozzle and drill it with a 2mm drill (not tested). But as said above, you first should try heating the nozzle and then use the needle again to clear a passage.

- If the upper aluminum part has clogged walls: Use a 2mm drill (not tested).

- If you feel that the nozzle itself is still clogged, use 0.35mm drill and carefully (slowly and gently) drill into the clogged plastic of the nozzle end (not the metal !). This may be dangerous for the nozzle.

Finally, reassemble, then extrude half a meter of plastic. This will help removing remaining impurities (turn the fan off)

... also read this thread in the Felix Forum

Filaments, temperature and fan

Polymers

The Felixprinter can print various types of polymers, but it's main "calling" is a PLA printer. ABS extrudes nicely at 245 degrees (I tested that) but it would not stick well to the default platform (see below for ABS printing)

As explained in the PLA article, various kinds of PLA need different temperature settings. In addition, you may have to change temperature according to the type of object you will produce. Typical PLA used for 3D printing extrudes at 210 degrees, but you can go lower or higher a bit.

Temperature

- Raise the temperature if

- filament doesn't flow well enough after changing to another plastic (i.e. first check if there is a problem with extruder arm tension)

- you print heavy simple block structures

- If you think that the nozzle may run into cold "towers" and rip the model off the platform. See also the fan settings.

- If you print structures with little filling which causes the nozzle to be "out of contact", i.e. filament will not be "pulled down" enough.

- Lower the temperature if

- Flow is a bit messy (too much filament at given times, walls unstable)

- If you have negative angles (object expanding upwards) and/or overhangs over a large space, e.g. a roof that has no support structures. For printing roofs with filling underneath I rather would raise the temperature...

- If you print small delicate pieces like a "hand on a Lego"

There is also an interaction between filament temperature and fan strength. On full fan strength you can print a bit warmer. Speed is another factor that will interfere. Very low speed and very high speed (feed rate) seems to be more difficult to extrude.

Typcial temperature settings for PLA filament (but I am not sure about this):

- Transparent blue or green PLA (from Felixprinter, wide rolls): 210 (I am pretty sure about this)

- Black PLA (from Felixprinter, wide roll): 205, maybe even a bit lower. Black PLA likes stringing IMHO. (I am not sure about this)

- Orange and red (non transparent PLA from Felixprinter, narrow roll): 207, except if you print fine parts and very little filling: 210 or even 215. If you encounter the problem that filament stops coming out, e.g. when printing small towers or large roofs over small filling, then (after checking extruder arm tension of course) you may go as high as 215, although print quality (overhangs) will suffer.

Fan

- The fan usually should be on. However if you print small towers on a small basis, you may reduce fan volume. Reason: If the print head bumps into some hardened (not so well extruded plastic) bit, it may rip the piece off the platform. If the PLA is still warm it may pass through. Same strategy can be used for printing large roofs that have many pillars underneath.

Another strategies for dealing with uneven bits that stick out:

- Print objects that tend to be ripped off with a raft that sticks

- Change fill type: Hexagonal is prettier but more difficult than lines

- Better than both "fan off" and "making it stick" strategies is to print slowly. Although you can't define regions other than 1st layers and roofs in the slicer software, you just can manually slow down printing to 25% or 50% or your "normal" speed.

Fills

Printing with small layers and using little fill (e.g. 15%) can be problematic. Typically you would print these at high speed, since it doesn't matter if there are imperfections. However, if filament is misaligned - typically within towers that have a small width - you may run into "clogging" problems: Filament stops coming out and then the whole print will be messed up ...

Solutions:

- Change the fill pattern. Simple lines may be easier.

- Use no fill and instead use thicker walls. That's a solution for small sculptures.

- Use more fill

- Reduce speed (start with that !)

Transporting the felix

One of the good reasons for buying a Felixprinter is easy transport. If you use a car, apply the same principle as with a child. Attach it on a rear seat with a seat belt...

I suggest, however, one modification to the design. Replace the screw that holds up the extruder arm with a longer one. The default short one can slip out and then you will have find all the washers again. In the plastic box delivered with the printer I found a screw that fits, although there is only space for a single bolt as you can see in the picture below (ok with me)...

SFACT/Skeinforge settings for PLA

SFACT/Skeinforge is the recommended slicer program. SFACT is based on skeinforge and basically allows to create configurations with less parameters. Generally speaking, Skeinforge, although it requires some waiting, seems to produce better results than Slic3r, however, so far we didn't test Slic3r. In our experience, it also turns out that some slicers can do some things better than others. In addition, Slic3r seems to be much easier to understand than Skeinforge, and SFACT/skeinforge is easier to understand than "normal" Skeinforge. Your choice.

If you use the included SFACT/skeinforge distribution, the default settings are ok for first prints. The print to the right was a small version of Pink Panther Woman by Pedro Januário (thingiverse) on top of a Lego. The bottom of the Lego piece is difficult to print and it came out better than with my other 3D printers. The woman on top is fairly easy to print, but some printers have trouble with the neck and the chest...

Unlock write permissions in the config directory

- Change permissions of the c:/Program Files (x86)/Repetier-Host/sfact_profiles/profiles/ directory for writing (advanced Windows settings). This way you can create other profiles in Skeinforge.

- However, only do that if you do understand what SFACT/skeinforge does. Also, I suggest to keep the all the included profile as reference, create new ones for your own designs and start from the one that fits best. Alternatively, you also could leave the directory in some other place and change the settings...

Temperature

Temperature is not set in SFACT/Skeinforge, but in the RepetierHost software.

- The default temperature of 210 seems to be ok for transparent PLA

- Some orange non-transparent PLA needed less, e.g. 205 !!. 210 will create problems with walls and bridges.

- Again: make damn sure that the nozzle is very close to the platform (1 or 2 sheets of paper)! Colder PLA will do even worse than warmer one if the distance is too big.

Fatter prints

Default skeinforge settings could be made a bit fatter for some objects like DUPLO blocks.

- Menu Slicer->Skeinforge configuration

In Skeinforge:

- Press the Craft button

- Press the Speed button

- Set the all flow scaler values a bit higher, e.g. 1.1 or 1.2

- Set the extrusion width bigger than 0.38mm (this parameter controls the spacing, and you could imagine setting it a tiny bit lower !)

Less fill

I then suggest to reduce the fill ratio if you want to gain some speed, e.g. 15% instead of 30% and to use a honey comb pattern.

- Press the Fill button

- Infill solidity = 0.15

- Use grid hexagonal for a more solid print. However, I noticed that this pattern can lead to irregular bits that stick up and then may cause the nozzle to rip off the model

For small mechanical pieces do the opposite, e.g. infill solidity = 1

More about SFACT and skeinforge

For now, see:

- SFACT slicer

- Skeinforge for RapMan (outdated, not appropriate for the Felix, but you get the idea ....)

- The official Skeinforge wiki

I will post some settings in 2-3 weeks from now ...

Printing with ABS

The Felixprinter in its current setup is designed for PLA printing. More precisely, while the extruder can handle ABS without problems, the print bed (platform) is not made for ABS IMHO, since the print will not stick enough. ABS needs to bond with either something like a scratched acrylic plate or a strongly heated platform. Fight warping is the main issue one has to face as with any other 3D printer.

However, objects with a small footprint can be printed fairly easily:

Add an acrylic plate on top of the print bed

Put an acrylic plate on top of the platform. I used a 8mm print bed spare part from my RapMan and attached it with 2 clips. I believe that an acrylic plate could be found in any good DYI store, also check with people/websites who do laser cutting (e.g. fab labs), e.g. check out the the supplier list from Fablab Amsterdam.

- Such plate should be sanded or otherwise roughened up (I just used a kitchen knife in the small print area I used).

- Then adjust the switching vane for the Z-axis. Raise the platform with Repetier Host until the bed is really close. Unscrew the vane, then move it until the green LED goes out

Switching back to PLA printing

- Adjust the z-axis first (switching vane).

- Extrude PLA at 220 degrees for a while, i.e. until the color and the flow are somewhat ok. Then go down to 210 and 205 and repeat. Extrude at least 500mm since bits of ABS can stick here and there in the extruder .

ABS setting in Repetier host

- Typical ABS temperature is 245 (that's what I used)

- No fan. Turn it off if it starts again after launching the print job. I believe that three things can happen when you leave the fan on. There will be less bonding (in particular in the crucial first two layers) and if the plastic is cold, new one added on top will increase warping since ABS warps in the direction of the warmer layer (cold is longer). Finally: if cold ABS imperfections stick out (up), there is a chance that the nozzle will rip the object way. So: if you leave the fan on for the first layers (raft plus 1st real layer), all your chances will be gone ....".

- Unheated platform, but I did not try if one heats it (you could)

- In addition you could close the window and heat your room. However, I don't think that ABS fumes are good for your lungs. The best ABS printers use a heated chamber in addition to a strongly heated print bed, so you also could build one of these ...

I suggest to print with a somewhat dense and fat raft as explained below, unless your object has a flat bottom, but I don't know what parameters you should then use for the first layer.

- Configure an SFACT profile for ABS:

- Select your favorite PLA profile first

- Menu Profile -> Profile ..... (then add yours)

SFACT profile

You must make changes in serveral places. Create a new profile, don't mess up a PLA profile that works.

SFACT Raft settings

- SFACT Select Craft / Changes to raft settings (highly provisional - Daniel K. Schneider 17:35, 6 September 2012 (CEST))

Interface Layers: 0 - 1

- 0 has the advantage that the object then can sit on the fatter base. You could use 1 (a single interface layer) with objects that are smaller than 2-3 cm on the base since then you can get them off more easily, but I found that using a dense single layered raft does just a fine.

Interface Feed Rate Multiplayer: 1 Interface Flow Rate Multiplayer: 2 - 4

- I use 4 since I can't teach SFACT to add more lines, i.e. the object on top will peel away

Interface Nozzle Lift over Interface Layer Thickness (ratio): 0

- Else the nozzle is too far

Base Layers (integer): 1 Base Flow Rate Multiplier (ratio): 2.0 or 2.5 or 3 (try, I use 3) Base Infill Density (ratio): 0.7 Base Layer Thickness of Layer Thickness: 1

- This is not typical, but else the nozzle is too far

Base Nozzle Lift over Base Layer Thickness (ratio): 0

- as above, nozzle must be close

SFACT Speed section changes

- Printing slower should help prevent warping, since the plastic can cool down in a more uniform way (IMHO)

Main Feed Rate: 60 Perimeter Feed Rate: 30 Object Layer Main Feed Rate: 25 First Layer Main flow Rate Multiplier (ratio): 1.2 First Layer Perimeter Flow Rate Multiplier (ratio): 1.2 Bridge Flow Rate: 1 Bride Feed Rate: 1

- However, these settings depends very much on your object and the quality you want to achieve. E.g. if you print an object that has long and high walls, you might try to slow down speed and maybe turn on the fan so that each layer could cool down quickly (just an idea, not tested).

SFACT Fill section changes

Extra Shells on Base (shells): 2

- This helps to get the first layer right (well, the 2nd attempt)

To try out

- Despite the above settings the first layer - i.e. DUPLO nibbles - doesn't stick very well, i.e. only the 3rd layer has about the right shape. Also, I need to figure out how to move the 1st layer still closer to the raft or interface layer. Maybe I should reduce print speed too, but then I hate waiting for too long...

- SFACT Dimension settings: I believe that something should be changed there too, since ABS does not extrude in the same way as PLA. Maybe also reduce extrusion width in Carve ?

- Differentiated temperatures for raft and model would be nice to have. I.e. use Skeinforge instead of SFACT. More complicated, but skeinforge has more options and also more recent code.

- Heat the platform. After waiting a while, the Acrylic sheet should heat too. Maybe this could prevent that the 1st print layer peals (warps) away from the raft. Also to be tried with flat bottom objects using no raft.

First ABS printing results

For the first print, I attempted a rather too large DUPLO. Longer than 3cm walls have tendency to warp upwards. The result is mixed. The shape is there, too much filling on the bridge (the flat top), and one corner severely warped (not shown, in the back)

For the second print, I used an easier 2x2 DUPLO with a Vigeland sculpture on top. I also adjusted some SFACT settings. In particular I had to make sure that the first layer was closer to the raft by entering "wrong" parameters. The result is satisfactory, but not as good as my PLA versions. Sorry for the bad picture quality...

Provisional conclusion: Printing ABS is as easy as with any other 3D printer I know of, if an acrylic plate is used and the fan is off. Only smaller objects can be printed without a strongly heated platform. Small here means: a small base layer and shorter than 3cm walls. A 6cm long wall may or may not print. Of course, larger objects can be printed, but they need structural changes in the design like holes in the walls. Also, flat objects like paperclips should do fine. Warping starts when several layers are piled on top. Btw: A heated print bed only will guarantee that the bottom of your larger model will print out fine. Warping may start again after a few dozen or hundred layers and for that only a heated chamber could help.

Oh, a final comment: I don't like printing with ABS very much since (a) it stinks and (b) results are IMHO not as precise as the ones done with PLA. I just took this up as little challenge since some types of models should be printed in ABS like stuff that is in contact with heat (e.g. tea) or smaller pieces that must be very sturdy. Also, ABS printing without fan allows to print objects with "towers" and tricky bridges where little things can stick out. Cold PLA may cause the model to be ripped off more easily than warm ABS...

Links

- FELIXPrinters (home page)

- Felix support forum