3D printer

<pageby nominor="false" comments="false"/>

Introduction

According to Wikipedia, retrieved 14:48, 14 October 2011 (CEST), 3D printing is a form of additive manufacturing technology where a three dimensional object is created by laying down successive layers of material. 3D printers are generally faster, more affordable and easier to use than other additive manufacturing technologies. 3D printers offer product developers the ability to print parts and assemblies made of several materials with different mechanical and physical properties in a single build process. Advanced 3D printing technologies yield models that can serve as product prototypes.}}

The two most popular 3D printing techniques are:

- fused deposition modeling, also called Fused Filament Fabrication (FFF). A typical example are low cost models like the RapMan

- Selective laser sintering: “an additive manufacturing technique that uses a high power laser (for example, a carbon dioxide laser) to fuse small particles of plastic, metal (direct metal laser sintering), ceramic, or glass powders into a mass that has a desired 3-dimensional shape” (Wikipedia, retrieved 14:48, 14 October 2011 (CEST))

- In addition, we should cite Laser cutting, a fairly simple to use technique to create "flat" 3D objects (although you can create designs that stick components together).

The opposite of additive manufacturing is subtractive manufacturing, e.g. using milling machines that take away material from an initial form.

See also:

- 3D printers in education and fab lab (for a wider picture)

- RapMan and articles in the RapMan category

- Software (listed below)

Hardware

(this section revised on oct. 2011)

Do it (almost) entirely yourself

Reprap 3D printers

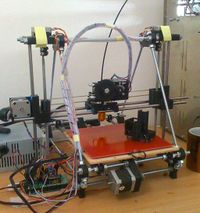

RepRap, a British project, is short for Replicating Rapid-prototyper. This type of 3D printer builds the parts up in layers of plastics. It can be assembled from parts bought in various places.

- Introduction to Reprap, retrieved 17:25, 24June 2009 (UTC).

Designs:

- Darwin. The design that inspired current (2010/11) Rapman and CupCake designs

- Mendel Overview (second generation Reprap)

- Prusa Mendel Overview (improved easier to build Mendel)

- Huxley Overview (travel sized mendel)

All RepRap printers can built with spare pars available from many places. However, this requires good "bricolage" skills. For those who don't have these, there exist many commercial kits that are relatively easy to assemble and also fully assembled kits (see below).

Resources:

- RepRap wiki. It includes many resources, like:

- RepRap Official Blog

- RepRap Project (Wikipedia)

- Designs can be shared on thingyverse.

- reprapsource. German company that sells spare parts.

Candyfab printers

Note: As of oct. 2011 this project seems to have stalled (no wiki update since 2009).

Cheap 3D open source printers

“We didn't know it, but it turns out that sitting around a table with folks while the MakerBot Cupcake CNC is puttering away and doing its thing and making objects appear where there were none before is really a great community activity! One of the gatherers mentioned that it felt like a geek campfire and it did!” (Pre Pettis, retrieved 17:30, 25 June 2009)

Below are the fabbers most popular in October 2011, sorted in alphabetical order. All organizations and companies providing designs and selling parts or fully assembled tools do have web sites with a lot of information.

BotMill

Botmill sells 3D Printers that use the (more recent) RepRap Mendel design.

- The Glider 3.0 3D Printer (Fully Assembled) costs $1400 (that's cheap compared to others)

- The older Axis 2.1 kit costs $1065.

Resources:

Bits from Bytes printers

Bits from Bytes produces and sells Reprap derivatives

Hardware:

- RapMan v3.11 (£750 / CHF 1270) is a device we acquired. We got it in January 2010 and was assembled by end of Feb 2010 Read the RapMan article. - Daniel K. Schneider Nov 2009/Feb 2010.

- A1 Technologies is a UK reseller

- New! - 3DTouch™ 3D Printer is an assembled 3D printer and costs £1,995.00 (single head) or £2,245.00 (double head). We recommend a double head system. The Education pack (£2,484.00) includes double head and plastic rolls. This models seems to be the successor of the BFB 3000 (or the same design ?)

Resources:

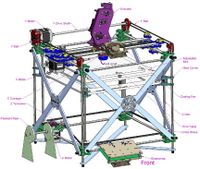

Fab@Home 3D printers

Fab@Home, is a project dedicated to making and using fabbers - machines that can make almost anything, right on your desktop. This website provides everything you need to know in order to build or buy your own simple fabber, and to use it to print three dimensional object. Hardware designs and software on this website are open source. This printer can include a dual syringe tool for printing two materials simultaneously.

Hardware:

- Fab@Home Version 2.0 - Kit for Single Syringe System costs $2125 (oct. 2011)

- A assembled Fab@Home V1.0 - Assembled Two Syringe System would cost $3500

Resources:

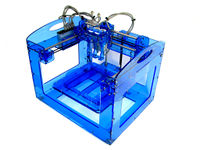

Makerbot printers

MakerBot Industries sells other RepRap-inspired designs. Like other Reprap derivaties, their 3D printers include a plastruder and an Arduino-compatible microcontroller and they work with several kinds of plastic, e.g. ABS (Lego-like) and HDPE (milk-jug like). The founder of this company also is involved in the RepRap research project.

Hardware: Currently, (2011) there are three versions:

- A free design called CupCake CNC and and its current (2011) Ultimate. Makerbot will sell the parts. I don't know if there is any difference in design with respect to the Thin-O-Matic kit.

- MakerBot Thing-O-Matic® Kit (formerly called Cupcake?) costs $1300

- Custom Fully Assembled MakerBot Thing-O-Matic® costs $2500.

Other devices are in development as documented in the Makerbot wiki (oct. 2011)

Ultimaker

Commercial entry-level 3D printers

We distinguish between commercial 3D printers that close source (below) and commercial open source/open design printers (in the previous section).

PP3dp / Up!

- PP3dp sells a light-weight 3D printer for about $2700 + shipping.

- According to the manufacturer the latest model includes a heated platform (good for ABS) and has 0.2 mm accuracy.

- Reviews: Ponoko, ....

Currently (oct. 2011) seems to be the easiest solution (by a large margin) to start printing, i.e. you can unpack and print and don't need to learn about calibration with tools like Skeinforge. On the downside (if I understand right) one only can print ABS in three settings (fine, normal and coarse). Also, the print area is small compared to a RapMan.

Resources:

- Official forum

- 3D Make blog (including "experiments")

Commercial desktop printers

- Desktop Factory 125ci 3D Printer (network compatible, about $5000, 1 cubic inch of "print" costs about $1). See also the Wikipedia entry. No idea, if this product is "real" - Daniel K. Schneider 16:02, 14 October 2011 (CEST).

- CreateItReal (Denmark) will sell a 3D printer for $3000. (planned for 2011, but not available in oct. 2011).

- Matrix 3D printer from Mcor technologies is a Laminated Object Manufacture printer, i.e. glues and cuts paper. You have to buy a package with an annual fee (e.g. £6600)

- uPrint from Dimension / StratSys (about $15000 or the $20000 for the uPrint plus multi-color model). These models use Fused Deposition Modeling with a 0.254mm resolution.

- HP Designjet 3D printer series is a uPrint from StratSys (see above). We don't know if it's totally identical.

- Alaris from Object offers two models. The 93 kg Objet24 Personal 3D Printer and the Objet30 Desktop 3D Printer print at 0.1mm resolution. Both use some kind of polymer jetting technology. Price on request

- 3D Systems sells a ProJet™ 1500 personal 3D color printer for about $/EUR 14500 and the VFlash monocolor for about EUR/$ 10'000. In addition, you have to buy material cartriges.

- The cheapest ZCorp (one of the industry leaders) model, i.e. the ZPrinter 150 is 164 kg and costs about $15'000. The multicolor version, ZPrinter 250, is $25'000.

web services for 3D printing

There exist probably several companies who do this. Typically, online 3D printing services also include a store where users can both upload and sell designs. Some sites also offer other manufacturing and commercial services and most also provide free resources for learning how to create things

Note: The laser cutting and engraving services will be moved once I decide to start resources on that topic.

- They take STL, VRML, Collada & X3D formats with some constraints, e.g. less than 500'000 polygons, a watertight mesh, etc.

- 3D printing and laser cutting.

- Laser cutting service. The company also provides Illustrator, CorelDraw and Inkscape templates

- Laser cutting (very similar or same as Formulor ?)

- Laser Cutting and engraving.

Software

Roughly speaking, the production pipeline looks like this:

- Model something or find a model

- (Merge/adapt models)

- Translate to STL

- Translate to machine code

Relevant EduTechWiki articles

In EduTechWiki, we provide a few overviews and/or beginner's tutorials

- First steps with the RapMan V3.1 3D printer

- OpenScad beginners tutorial (3D modeling with code) and Doblo factory OpenScad routines for creating DUPLO/LEGO clones

- Sketchup 3D printable objects tutorial (3D modeling with this Google tool)

- Sculptris (3D modeling by sculpting)

- Skeinforge for RapMan (G-code generation for the rapman) and G-code (overview)

- Meshlab for RapMan tutorial (translating file formats, mesh merge)

- Netfabb Studio tutorial (positioning, dimensioning of STL files for printing, simple object creation/merge)

3D Software See:

File formats

The most popular file format is the .STL file format: “An STL (“Stereolithography”) file is a triangular representation of a 3-dimensional surface geometry. The surface is tessellated or broken down logically into a series of small triangles (facets). Each facet is described by a perpendicular direction and three points representing the vertices (corners) of the triangle. These data are used by a slicing algorithm to determine the cross sections of the 3-dimensional shape to be built by the fabber” (The StL Format, retrieved 17:25, 24 June 2009 (UTC)). STL files can be created with most CAD programs. Alphaprototypes provides instructions for several popular CAD applications.

Special-purpose software

- ReplicatorG is the software that will drive your CupCake CNC, RepRap machine, or generic CNC machine. You feed it GCode, it parses the GCode, and then controls your machine via a driver. Its cross platform, easily installed, and is based on the familiar Arduino / Processing environments.

- CandyFab developed CandyFaboulous, written in Processing, an open source programming language and environment for people who want to program images, animation, and interaction.

Links

See also the Fab lab article which also includes a bibliography.

Repositories

- New objects (includes visualization and downloadable files)

- 3dprintables.org (excellent wiki includes educational objects, often with links models on external sites)

- Thingiverse (a place to share digital designs that can be made into real, physical objects). Many interesting objects for RepRap machines like the RapMan

- See also "online printing services" (above)

General

- 3D printing directory. (dead link ? on oct 14 2011)

- 3D Printing (Explaining the Future, oct. 2011). Includes a review of both commercial and open source printers.

- Three dimensional printing Laboratory (MIT,last update 2000)

- The next Napster? Copyright questions as 3D printing comes of age by Peter Hanna, ArsTechnica, 2011.