Fabbster 3D printer

Introduction

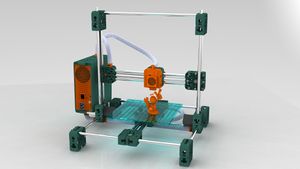

The Fabbster is a low cost 3D printer kit that can be assembled by people with some do-it-yourself skills.

Important. This article refers to a "pilot program" printer and the draft manual version 1.10 and not the "final" home-user version. - Daniel K. Schneider 14:11, 24 April 2012

See also:

- Fabbster assembly (some assembly notes)

- Fabbster testing and setup (including software installation and calibration)

- Netfabb engine for RepRap (notes and links for the control and slicer program)

- Netfabb engine for fabbster build styles (Styles you could use)

- 3D printing category and its 3D parent category...

The fabbster kit

The fabbster is a kind of modified Mendel design that targets the home market.

Where and what

Getting it The kit is sold through retailers and costs about 1500 € (incl. VAT., e.g. here). It will be shipped sometimes soon (May 2012?). I got ours for 500 € through their (March 2012) pilot program.

Software

- A basic STL manipulation / slicer / control program (STL to machine code configurator/translator) from Netfabb is included in the price. The machine code is closed source and not documented, meaning that you will have to use this Netfabb program.

- The printer comes with an electronic box that can print either through a connected PC or via a SD card. You also can put a file on the SD, then launch it from the PC (this is better solution for large files)

- Driver software for Windows XP/VISTA/7 can be downloaded from the wiki.

Materials

- Custom made ABS sticks or 3mm ABS rolls

- PLA sticks or rolls

The parts

Unlike the RapMan, the fabbster is based on very few different kinds of parts:

- Most of the structure uses so-called "cassettes", i.e. good for most everything 8.5x7.6cm plastic parts

- Most screws and bolts have the same size.

Assembly

- See Fabbster assembly (some assembly notes)

The assembly manual

- Assembly is described in a bilingual German/English assembly handbook (Version 1.10 is a color PDF file in A4 portrait format and includes 57 pages and about 42 for the assembly process itself.

- Steps are explained on sheets that included the following information:

- Parts (prepare them first)

- A graphic explaining the assembly step

- Some detail views

- A global progress view

Other documentation

- Wiki

- support forums

Build time depends:

- On your DYI skills

- On your technical reading skills

- On your capacity to follow instructions (undoing is easy, but adds time)

- On how well you want it to be done

- On how fast (without breaks etc) you plan to work

In my opinion, it can be anything between three and thirty hours (or more if you make a lot of mistakes). It took me about 22 hours (including initial testing, wiki writing etc.). Pure assembling therefore took less. But I do count problem-solving and basic testing as "build time".

Important: Build time refers to the pilot version. The final home-user version should take much less time.

Quality of the draft manual:

The draft manual is well done, but should be improved a bit as most pilot participants pointed out, e.g.

- some mistakes must (will) be fixed,

- some explanations must (will) be added,

- Insert upfront a graphic that labels the most important elements (axis, names of the motors). e.g. see this. Users must understand what they are building. Some won't ....

Quality of parts of the pilot model

- Some parts don't fit well: Fabbster is in the process of fixing this

- 1-2 parts need a redesign: Fabbster is in the process of fixing this

- The testing/calibration/software installation part is currently badly documented: Fabbster will fix this too I hope :)

If I had to assemble a second one, I'd certainly do it in 4 hours but then I wouldn't. Once every two years is enough (see RapMan).

First impressions

I didn't play for a long time with this printer yet. With respect to the RapMan it is easier to assemble (however some parts didn't fit too well and needed filing or hammering, and that is being fixed by fabbster). The geometry and the belts are much easier to calibrate and it can print faster.

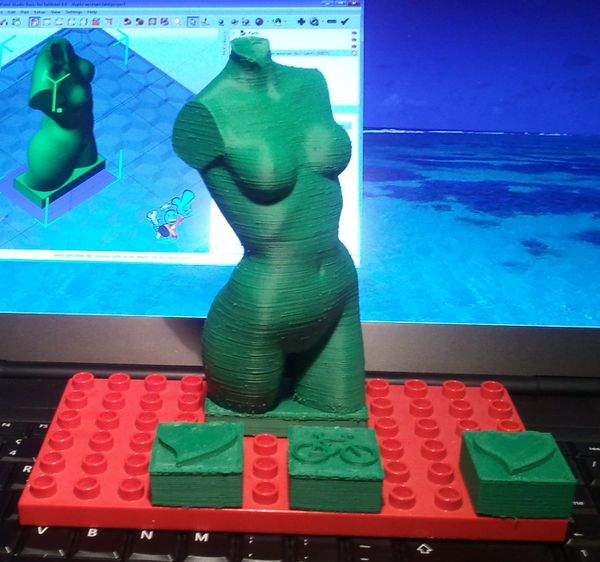

So far, I didn't manage to create any high quality prints, since the extruder of this printer is designed to work with sticks that will arrive later. 3mm plastic rolls work fine if you keep to medium width. Very low RPM does not work for me. Below a picture of some of the first prints. Too much material on the roofs, and a bit too much in the walls (you can see squeeze on the lady) but that can and will be fixed - Daniel K. Schneider 12:45, 12 May 2012 (CEST)

Also, I didn't manage to print with (old transparent and brittle) PLA so far ...

After

(by Daniel K. Schneider (talk) 16:27, 22 October 2020 (CEST))

Fabbster never managed to deliver what they promised:

- Firstly, it took them ages to explain folks how to use it with standard filament, see my own contribution in Netfabb engine for fabbster build styles.

- Second, they never got the sticks mechanics and economics going...

- Third, it took them a long time to make the frame rigid enough and to build a decent enough extruder.

Finally, they stopped the project. After trying hard to make this printer work I got my Felix 1.0 3D printer which did its job better (and as of 2020 it actually still works, although I don't use it anymore). Some years later I gave the fabbster to a student, telling her that trying to make it work is a learning experience but that she should not take it as a punishment. The only really positive experience was the Netfabb slicer that we got, probably because the company behind the project (Sintemask) built commercial 3D printers and had good relations with Netfabb. Back then, a really advanced (but proprietary) software, e.g. one could define "styles" for given regions.

Links

- Official

- Fabbster Home

- Fabbster forums

- Fabbster wiki (Includes all the documentation). Sometimes, a wiki page just links to a file, e.g.

- assembly handbook

- drivers and software