Netfabb engine for RapMan: Difference between revisions

| Line 168: | Line 168: | ||

Skeinforge: | Skeinforge: | ||

* Let's you control many parameters that define printing (globally) | * Let's you control many parameters that define printing (globally) | ||

* | * User decides everything | ||

* is free | * is free | ||

Netfabb: | Netfabb: | ||

* has a calibration procedure that identifies precise features of a printer | * has a calibration procedure that identifies precise features of a printer | ||

* implements dynamic printing, i.e. different handling of different kinds parts, i.e. fine prints are printed much slower and with less filament | * implements dynamic printing, i.e. different handling of different kinds of parts, i.e. fine prints are printed much slower and with less filament | ||

* is easier to use, i.e. user only defines print quality (vs. print time) | * is easier to use, i.e. user only defines print quality (vs. print time) | ||

Performance: | |||

So far, I only made test with [[http://www.thingiverse.com/thing:2608 a combination]] (download) of a [[doblo factory|duplo-compatible block]] and an artistic hand. | |||

[[image:doblo-lugo-hands.jpg|frame|none|Doblo + hand / Lugo + hand benchmarks]] | |||

Doblos underneath: | |||

[[image:netfabb451-vs-skeinforge2.jpg|frame|none|Comparison test]] | |||

Doblos standing: | |||

[[image:skeinforge-vs-netfabb451.jpg|frame|none|Comparison test]] | |||

At various speeds and settings the result is fairly consistent: | |||

* Hand is better with Netfabb | |||

* Block (in particular the roof) is much better with Skeinforge | |||

When I print the same object in Lego size (x,y,z divided by 2) both have trouble printing the Lego block more or less correctly. | |||

== Links == | == Links == | ||

Revision as of 17:38, 29 April 2010

Introduction

The netfabb Engine for RapMan Basic is a cheap Software Suite to generate a g-code for a RapMan 3D Printer.

The Engine is based on the free netfabb Studio Basic, i.e. when you buy the engine for RapMan you get another version of Studio Basic that includes the same functionalities (mesh edit and repair functions) plus the g-code generator.

Calibration

The calibration part

Unlike skeinforge, this software works with a calibration procedure. For each kind (an color) of polymer, you will have to print out 16 calibration squares whose walls you then have to measure with a caliper.

In other words, netfabb Engine figures out the properties of your printer through calibration.

Problems with printing

We found that the calibration file for version 4.5.1 could not be printed with the default settings or without "truly manual help".

- Solutions

In the expert settings, we reduced temperature range and halved print speed and RPM for the rafts.

As an alternative or in addition:

- Just when it starts printing the rafts (after printing the pillars), hit ESC and raise the temperature for ABS to something over 250. It doesn't matter if the raft sticks to the calibration walls. Be careful with PLA. If it is higher than 215 with ventilation or higher than 210 without, it may "weaken" and will block because it has become "wobbly" and can't be pushed anymore.

- press down by hand the filament while the rafts on top of the pillars are printed. Dont't do this of course when it prints the calibration walls, filament should come in ok.

For PLA (rapman v3.1, 2.08 firmware, BFB pre-assembled hot end):

- Temperature low = 205

- Temperature high = 210

- Extruder speed (RPM) = 50

- Speed = 25

For red ABS

- Temperature low = 245

- Temperature high = 257

- Extruder speed (RPM) = 50

- Speed = 25

Print bed of the RapMan was a tight 5 sheets of 75g recycled print papers away from hot end.

In addition: you could lower all print speeds, but I refrained from that.

- Explanation attempt

When the RapMan goes into "overdrive", i.e. "ultra speed" plus extrusion rate of 2800 (280 RPM) or higher, the stepper motor can't pull in enough filament since there is some "holding back" if you use the standard RapMan setup (filament coming along the black cable housing). Since both PLA and ABS is rolled this can create some tiny tension that is bad enough to stop the flow at a speed of 50 and higher extrusion rates. Btw. some experts seem to make their filament coming directly from the top, i.e. they build a filament holder that then is attached to the ceiling...

Measuring

Once you got the test calibration part printed you will have to measure each wall. Here is some advice I got from both the manual and the BFB forum.

- Take three measures at least for each.

- Take the smallest one (except if you think that it's a printing failure)

- Hold down the caliper towards mid-height of a wall

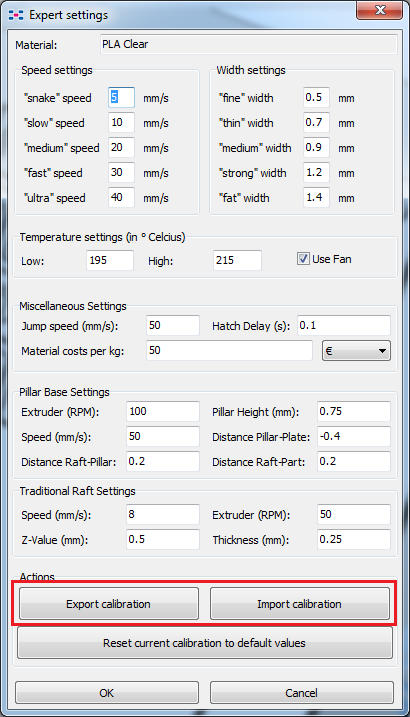

Calibration profiles and expert settings

After calibration, Netfabb will not remember values for individual letters, but compile all the data into a profile. Some of these data can be changed through the expert settings:

Under Windows, Netfabb will store the profiles somewhere in your home/application data (that can change from windows to windows version) E.g.

C:\Users\_YOU_\AppData\Roaming\NetFabb\bitsfrombytes ~/NetFabb/bitsfrombytes/extruder1_bfb_pla_translucentgreen.xml

You also can export/import these files via a menu in the expert settings.

Example file: Translucid PLA - April 2010

<root>

<layersize>0.25</layersize>

<temperature>

<high>212</high>

<fan>1</fan>

<low>207</low>

</temperature>

<calibration_support>

<speed>8</speed>

<extruder>32</extruder>

<z>0.400000005960464</z>

</calibration_support>

<material>

<costs>0.0500000007450581</costs>

<currency>1</currency>

</material>

<pillar_raft>

<extruder>50</extruder>

<speed>25</speed>

<downz>-0.400000005960464</downz>

<top>0.75</top>

<spacing1>0.100000001490116</spacing1>

<spacing2>-0.400000005960464</spacing2>

</pillar_raft>

<hatchdelay>0.100000001490116</hatchdelay>

<fastspeed>50</fastspeed>

<traditional_raft>

<speed>8</speed>

<extruder>50</extruder>

<z>0.400000005960464</z>

<thickness>0.300000011920929</thickness>

</traditional_raft>

<speeds>

<snake>5</snake>

<slow>10</slow>

<medium>20</medium>

<fast>30</fast>

<ultra>40</ultra>

</speeds>

<widths>

<fine>0.5</fine>

<thin>0.699999988079071</thin>

<medium>0.899999976158142</medium>

<strong>1.20000004768372</strong>

<fat>1.39999997615814</fat>

</widths>

<filament>

<name>default_layersize</name>

<layertype>default</layertype>

<medium>

<fast>75.9375</fast>

<slow>25.3124980926514</slow>

<snake>14.2382793426514</snake>

<ultra>90</ultra>

</medium>

<fine>

<medium>10.6292524337769</medium>

<slow>8.68055438995361</slow>

<snake>4.807692527771</snake>

</fine>

<thin>

<fast>56.5384635925293</fast>

</thin>

<strong>

<medium>55.2960052490234</medium>

</strong>

</filament>

<filament>

<name>half_layersize</name>

<layertype>half</layertype>

<fine>

<medium>12.5</medium>

<snake>2.4038462638855</snake>

</fine>

<thin>

<fast>46.7727241516113</fast>

</thin>

</filament>

<filament>

<name>double_layersize</name>

<layertype>double</layertype>

<medium>

<fast>109.349998474121</fast>

<slow>29.7551021575928</slow>

<snake>15.0619821548462</snake>

<ultra>202.499984741211</ultra>

</medium>

</filament>

</root>

Netfab vs. skeinforge

Skeinforge:

- Let's you control many parameters that define printing (globally)

- User decides everything

- is free

Netfabb:

- has a calibration procedure that identifies precise features of a printer

- implements dynamic printing, i.e. different handling of different kinds of parts, i.e. fine prints are printed much slower and with less filament

- is easier to use, i.e. user only defines print quality (vs. print time)

Performance:

So far, I only made test with [a combination] (download) of a duplo-compatible block and an artistic hand.

Doblos underneath:

Doblos standing:

At various speeds and settings the result is fairly consistent:

- Hand is better with Netfabb

- Block (in particular the roof) is much better with Skeinforge

When I print the same object in Lego size (x,y,z divided by 2) both have trouble printing the Lego block more or less correctly.

Links

- Netfabb