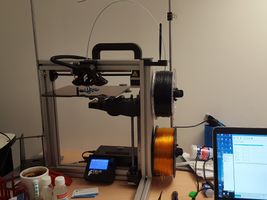

Felix TEC-4.1 3D printer

Introduction

The Felix TEC4.1 is a 3D printer made by FELIXprinters and that started shipping in 2018. It features semi-automatec calibration of the print bed, an optional dual head, etc. and strong, reliable steel extruders. This article shortly describes some of my experience and (if I find some time in the future) some tips. Since 3D printing is now main stream we will refrain from explaining basic use.

This model is an evolution of the Felix 1.0 3D printer we bought in 2010, the Felix 2.0 3D printer we got in 2013 and the Felix 3.0 we did not buy. Make magazine rated the older 3.1 model in fourth position in 2018. The TEC 4 is better. This makes it probably the best (non back breaking) easily portable 3D printer.

- Daniel K. Schneider 26 nov 2018

See also:

- RapMan (our first 3D printer assembled in Jan 2010, not used any more, but no modern printer will beat its look)

- Fabbster 3D printer (given away)

- Felix 1.0 3D printer (bought in 2012 and still working)

- Felix 2.0 3D printer (bought in 2013, given away, still working)

- Felix Pro 1 3D printer (bought in 2015)

Further information from the manufacturer:

- Downloads for FELIX Tec 4 (Manuals, Tips, Printables, Firmware, etc.)

Technical specifications

- Layer resolution

- Minimum layer height: 0.05 mm,

- Maximum layer height: 0.25 mm

- Extruder / nozzles

- Single (Dual hot ends on option)

- 0.35mm (0.25, 0.5mm, 0,7mm options) nozzles

- Max 275 C

- Print volume

- 255 x 205 x 225mm

- Print bed

- Kapton coated.

- heated, up to 90 C ?

- Detachable and flexible (quick removal of prints !)

- Semi-Automatic calibration (For leveling, a Z-Sensor will probe and then tell which of the two buttons to turn and how much. For z-probe, this is done through the control)

- Dimensions and weight

- 10kg

- 410 X 450 X 520 mm

- Print materials

- Many (PLA, TPE, ABS, PVA, Wood, Glass, PET(G)

- Software

- In principle, one could use any controller/slicer software. As of Nov 2018 there are profiles for the following controller/slicer software: Repetierhost (Cura), Simplify3D (commercial). Repetierhost is configured and distributed through Felix.

- Connectivity

- USB Cable (I prefer that, since I can more easily control the printer during printing. I also find filament changes easier to do through Repetierhost)

- SD Card (practical for students)

Unpacking, assembly, configuration, calibration

Unboxing

The box arrived in good shape and unboxing is easy and fast. It was ordered on Tuesday Nov 20 and arrived in my office on Monday morning, Nov 26, 2018.

- Unboxing and readying the Felix TEC 4.1

Assembly

I takes about 15 minutes to unpack and assemble the printer.

- 5 plastic strips that hold elements in position have to be cut

- the handle on top has to be fixed

- filament guide has to be clipped on the frame

- filament holders (optional) have to be clipped and positioned

- The magnetic flexible build plate has to be put in the right position on top of the platform

PC Configuration

Download Repetierhost as distributed by Felix. The installation also will propose to install a serial driver.

Calibration

The printer is shipped with a 23 pages quick start guide. It includes

- 8 pages of specifications, basics, part list, unboxing, handle fixing, etc.

- The calibration routine for a single head printer takes two pages. I carefully read these, since this a new feature for me.

Calibrating means two things: (1) Making sure that all spots of the build plate have the same distance to the print head and (2) it should be a the right distance, i.e. the thickness of a business card. The first is done by semi-automatic hardware calibration, the second by software, i.e. in the printer's parameters. The printer may just work out of the box but I did not try that.

Platform leveling

- The build platform must be leveled.

- In the display unit, select control->Level Build PLT.

- Turn front or rear wheel left of right X degrees as displayed, then test again.

Z-Probe calibrating

Calibrating the Z-Probe, i.e. adjusting the right z height is done via software (i.e. the printer will remember). Here are my slightly modify tips, since the instructions are a little less clear.

- Put a large sheet of thick paper (120g) or two sheets of ordinary printer paper on the platform.

- Click Control->Calibrate Z-Probe

- Now if your paper is stuck on the platform, i.e you cannot remove move the paper, turn the wheel right to lower the platform

- If you wish you now can insert the Felix calibration card

- Then turn the wheel left to rise the platform until there is a good amount of friction, i.e. you can still pull the card away without damaging it (I prefer the first layer to be very close).

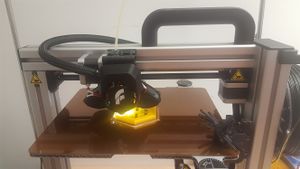

First prints

There was no failed print nor any trial with the Felix logo that ships with RepetierHost. I used Repetierhost 2.05 for FELIXprinters, freshly downloaded after uninstalling an old version. I did not try Simplify 3D so far.

- First print was a spinning top with special (strong) using Felix PLA and default slicer values. After the print, I re-calibrated the Z-Probe as described above since the the first surface layer was not squashed enough. I used the Felix calibration card, but with a good amount of friction. I also may increase flow rate a bit and printer with a slightly higher temperature... more about this later when I find time to print more complex objects.

- Second print was a Beekee box with PETG from Felix (not completed at time of writing). I raised default temperature a bit to 220 degrees and slowed down first layer speeds a bit.

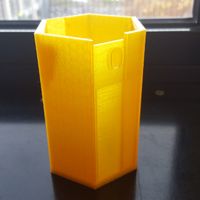

- First two prints

First print, a simple spinning flower top I designed.

Second print, Beekbox, designed by a TECFA team, led by Vincent Widmer (PhD student).

Second print, Beekbox printed.

Summary

Unboxing, readying, and calibrating was easy and the first print went well.

I really do like the new flexible platform. It can be removed and put back easily.

I probably will like this printer better than the Felix Pro 1 3D printer since it seems to be more robust.

- The Pro1 does have a sensitive Z sensor that can require hardware calibration work once it experienced stress (see next item). Since semi-automated calibration is easy I don't need fully automatic calibration, although it is a nice feature.

- My Pro1 has a second print head. This is interesting for printing with different plastics for support, but a second print head can become a problem spot when printing large horizontal structures that may have slicer mistakes. E.g. I did managed to get the print heads ripped off with a vulcano for example.

That being said, I now returned the Pro1 for a Pro2 upgrade and I will be able to compare two printers of roughly the same age.

Slicer settings

The default slicer settings defined in the Felix Repetierhost distribution can be trusted for typical prints as far as we can tell. That being said, adjustments have to made for some types of objects and more importantly, for other filament types and makes. Below, we will write down some parameters used for some more difficult objects.

Soft PLA

Bought from Printerstore (49.50 CH / kg ~ 45 Euros ). Compared to NinjaFlex this is rather cheap.

The following settings were use for a large, 25cm x 6cm Custom laptop cooler stand.

- Temperature = 220

- Bed temperature = 40 (0 also should work, since soft plastic usually sticks very well to Kapton)

- Flow = 95%

- First layer speed = 20 mm/s

- Base print speed = 40 mm/s

- Perimeters speed = 30 mm/s

Tip:

- To remove a soft PLA print, spray some alcohol along the edges and wiggle the platform so that it can enter underneath.

- One might use a 0.5mm nozzle for printing soft plastics to speed up the printing, but for now I didn't want to exchange the hot end.

Links

- Official

- FELIX Printers (Netherlands)

- FELIX Printers @ Facebook

- FELIX Printers on Twitter

- FELIX Printers on LinkedIn

- FELIX USA (I don't know if this is just a franchise)