G-code

Introduction

According to Wikipedia, “G-Code, or preparatory code or function, are functions in the Numerical control programming language. The G-codes are the codes that position the tool and do the actual work, as opposed to M-codes, that manages the machine; T for tool-related codes. S and F are tool-Speed and tool-Feed, and finally D-codes for tool compensation.”

See also

- Grbl a low cost alternative to parallel-port-based motion control for CNC milling that accepts g-code.

- Slicers and user interfaces for 3D printers

- Skeinforge for RapMan (A popular slicer program for RepRap and other machines)

Arduino g-codes

- See G-code page at RepRap wiki.

List of G-codes for the Rapman

This is a g-code page for the RapMan printer.

List of RapMan G-code (thanks to Bits from Bytes blog: RapMan special codes

| Code | Explanation | Example |

|---|---|---|

| G0 | Rapid Motion in X, Y, and Z axes. | G0 X10.0 Y20.0 Z1.15 |

| G1 | Coordinated Motion in X, Y, and Z axes with speed F mm/minute. | G1 X10.0 Y20.0 Z1.15 F960.0 |

| G2 | Arc – Clockwise (Not used by Skienforge) | |

| G3 | Arc - Counter (Clockwise Not used by Skienforge) | |

| G4 | Dwell Time | G4 S20 |

| G20 | Inches as units used | G20 |

| G21 | Millimetres as units used | G21 |

| G28 | Go Home (far left) | G28 |

| G90 | Absolute Positioning | G90 |

| G92 | Set current as home | G92 |

| M101 | Turn extruder on (forward/filament in). | M101 |

| M102 | Turn extruder on Reverse (Still to add) | |

| M103 | Turn extruder off. | M103 |

| M104 | Set target temperature to 245.0 C. | M104 S245 |

| M105 | Custom code for temperature reading. Not used | |

| M106 | Turn fan on. | M106 |

| M107 | Turn fan off. | M107 |

| M108 | Set Extruder speed to S value/10 = 40rpm. | M108 S400 |

| M220 | Turn off AUX V1.0.5 | M220 |

| M221 | Turn on AUX V1.0.5 | M221 |

| M222 | Set speed of fast XY moves | M222 |

| M223 | Set speed of fast Z moves | M223 |

| M224 | Enable extruder during fast moves | M224 |

| M225 | Enable extruder during fast moves | M225 |

| M226 | Pause RapMan as if pause button pressed | M226 |

Typical file headers produced by the Skeinforge program

| G21 | millimeter system selection | |

| G90 | absolute distance mode | |

| G28 | Return to home position | |

| M222 S800 | Manually added to file. Set speed of fast XY moves. Default value 500 -V1.0.5 | |

| M223 S768 | Manually added to file. Set speed of fast Z moves. Default value 500 -V1.0.5 | |

| M103 | Turn extruder OFF. | |

| M105 | Custom code for temperature reading – not used by RapMan | |

| M104 S247.0 | Set temperature to 247.0 DegC. | |

| G1 X0.0 Y0.0 Z0.0 F480.0 | example of linear interpolation at speed 480 | |

| M101 | Turn extruder ON. | |

| Main | code follows | ..... |

Example code

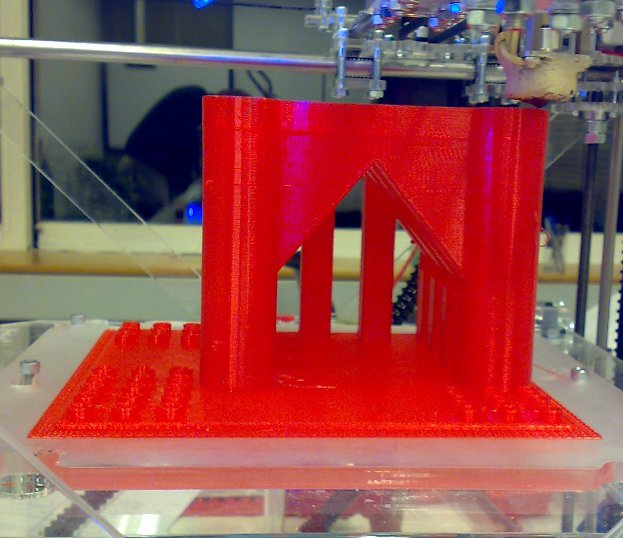

Lines 1-12 from a Duplo-compatible block with a vertical hand on top (6.4cm X 6.4 cm x 13.5cm). The file has 79009 lines (!) and prints at medium speed/quality.

G90

G21

M103

M105

M113 S1.0

M104 S255.0

G1 X-8.64 Y-69.23 Z0.84 F60.0

M101

M108 S595.0

G1 X-8.64 Y5.87 Z0.84 F200.0

G1 X-4.32 Y5.87 Z0.84 F200.0

G1 X-4.32 Y-69.23 Z0.84 F200.0

Lines 1057 and forward

M103

M108 S350.0

G1 X0.36 Y-63.63 Z2.72 F960.0

M101

G1 X0.36 Y-63.64 Z2.72 F1200.0

G1 X63.64 Y-63.64 Z2.72 F1200.0

G1 X63.64 Y-0.36 Z2.72 F1200.0

G1 X0.36 Y-0.36 Z2.72 F1200.0

G1 X0.36 Y-62.91 Z2.72 F1200.0

M103

G1 X1.15 Y-62.86 Z2.72 F960.0

M101

G1 X1.14 Y-62.86 Z2.72 F1200.0

G1 X1.14 Y-56.39 Z2.72 F1200.0

G1 X2.64 Y-56.39 Z2.72 F1200.0

G1 X2.64 Y-55.61 Z2.72 F1200.0

G1 X1.14 Y-55.61 Z2.72 F1200.0

G1 X1.14 Y-40.39 Z2.72 F1200.0

Recovery from printing abortion

Printing stopped at line 299941 after 3 days of printing. I mean I had the printer on hold sometimes (ESC), but it was a 24 job. Anyhow, big low down, but I decided that I must recover from this without super glue, i.e. leave the object on the print bed and restart.

If you don't know where it crashed, e.g. if the board did reset: Run skeinforge again but make a change in the Analyze->Skeinview tool:

- Change Mouse Mode to Display Line. You then can identify both the layer and the spot where it stops in this tool. Then click on a drawing it will display the g-code line...

Now if you were printing a tall object, the problem is that the rapman always expects to be able to home in order to find x,y,z = 0. If you have a "real" print it can't, since raising the print bed will destroy a 14cm high print for example.

I tried all sorts of things fiddling with G90 and G92 codes, but did not mange to restart g-code where the printer left.

G90 G92 X0 Y0 Z-142 or G90 G92 X0 Y0 Z142

So I came up with a typical bricoleur solution :(

- Fix the g-code to start at z=0

- Fool the printer to believe that it is at z=0

Here are the two steps:

(1) Fixing the g-code file

Normally, you should write a script (argl for stupid end-user programmers) that replaces all the Z values. E.g. Z142.2 should become 0 or 0.2. In my case I was lucky since I just print vertically. So I decided to restart at 14cm and not 14.2cm (makes it higher, but that's fine).

GCode where it stopped:

G1 X-90.5 Y68.33 Z142.2 F960.0

So I went to start of the 140mm series and killed all the lines from beginning to there. Then I used three Regexps with a text editor (emacs) to change:

Z14\(.\)\(..\) by Z\1\2 Z15\(.\)\(..\) by Z1\1\2 Z16\(.\)\(..\) by Z2\1\2

Then of course, the g-code must have a header. Resulting g-code start:

G90

G21

M113 S1.0

M108 S380.0

M104 S210

M101

M103

M108 S380.0

M106

M103

G1 X40.96 Y-19.95 Z0.2 F869.59

M101

G1 X39.55 Y-18.93 Z0.2 F960.0

G1 X36.66 Y-17.64 Z0.2 F960.0

If your object is flat, you can stop here, else read on ....

(2) Fool the printer

a) Move the print head next to a top level point NEXT to home. Path toward -X (left) must be unobstructed. Then align it, i.e. make it touch the top.

b) Move it to the left a bit, and switch off.

c) Switch on. Then position the print head about 1mm below the point where you want to restart. This can be a bit less or more. You can see how much you go down on the control panel. I.e. press the Z+ button and move the print board up.

d) Switch off

e) Hold you finger on the Z switch (grey box which is usually touched by the long 6cm bolt. Run the file and release after 1-2 seconds, i.e. the print bed should move down again by 1mm.

f) Now the printer will move to Xmax/Ymin. If it barely scratches the print when it moves you are fine. If it is too high or too low, then repeat from (c). Took me about 4 attempts to get this right.

Remarks

I REALLY think that rapman firmware should include a control code to recover more easily e.g. Some g-code that says:

- Home to X=0 and Y=0 (but leave Z ALONE)

- Read from the G-code file the current Z-position (e.g. Z=142.2)

- Then just print ....

There is a plan for future firmware to fix this. See this post by Ian - 22:22, 2 April 2010 (UTC).

I did manage to print this stronghold, see the Doblo factory article.