Trotec Speedy 100R

Introduction

This page will document the Trotec Speedy 100R that TECFA (me) that we just acquired - Daniel K. Schneider (talk) oct 2016

As far as I can tell for now, we will use this machine to create three types of objects:

- 2D objects, e.g. badges, games and toys (created from simple SVG drawings)

- 3D structures to assemble from 2D elements (created from simple SVG drawings), e.g. animals

- 3D structures glued together (made from sliced 3D objects). The slicing can be done with various tools, e.g. Netfabb, Slice3R, 123D Make.

All cut parts also can be engraved, either vector engraving or raster engraving (typically from pictures).

Specifications of the 100R at TECFA

This system easily fits into an office and it just needs two electrical standard plugs.

Speedy 100R

- 50 W CO2 laser (Iradion tube)

- 2 inch lens (standard)

- 61cm x 30.5cm working surface

- 180 cm/sec speed

- Box size: 982 x 780 x 457 mm

- 80 kg

- Air cooling

ATMOS Compact exhaust fan

- 815 x 675 x 555 mm

- 88kg

Official home page:

Laser cutting parameters

There are several parameters that must be set (you can create profiles for that)

Basic

- Cutting power, typically 100

- Cutting speed, typically 1

- Cutting pulse (faster = stronger, but more inflammable), typically 1000

- Engraving power, typically 50

- Engraving speed, typically 100

- Engraving resolution, typically 500PPI

- Material thickness, typically 2-5mm

Advanced

- "Print file creation" parameters can define whether using the standard color scheme (e.g. hairline red for cutting and black for engraving) and how to render pictures, etc.

- Repetition for both cutting and engraving. Some materials need 2-3 passes.

Outline of the workflow

Preparation steps

(0) Clean the lens (with a microfiber cloth or equivalent)

(1) Switch the machine on

(2) Place work piece

- open cover

- Place piece into upper left-hand corner, against horizontal and vertical rules

(3a) Focus laser beam (manually)

- By default (for the mid-resolving lens) the beam is located 5.08 cm (2.0 in) below the lens.

- Position the processing head over the work piece

- Hang the focus tool on the external ring of the working head

- Then, move up (by little steps) the working table

(3b) Alternatively, focus laser beam with software

- Click the icon “focus laser” in the Trotec JobControl (make sure that material thickness, table height and lens type are OK !)

Create a graphic

- Any vector graphic will do, since jobcontrol will work from the print file, i.e. the control software will analyse the postscript and let you configure the print from there.

- However, we noticed that something doesn't work properly with Inkscape drawings (old 0.4x version), i.e. TroTec Job control cannot identify some vectors. Try producing a PDF first ("print to PDF file" in Inkscape), then print the file from PDF. Anyhow, make sure to install the latest version of Inkscape and read Using Inkscape for laser cutting

Preparing the print file

From your drawing or rendering software, File->Print the drawing

- Select as printer

Trotec Engraver - Click on

Preferences - Define (at least):

- Material parameters, e.g. a setting you defined for a given type and thickness of Material (these parameters, however can be changed later)

- Algorithm (e.g. for simple vector-based cutting and engraving use color, if there are pictures, you could try Optimization, Stucki, etc.)

Then click bottom "print" icon and "print" again from the Windows software. Trotec JobControl now will open and the print file should appear in the jobs queue to the right.

Job Control software

In the Job Control software, verify or specify all the parameters

Establish Connectionin JobControl- On the laser move the cutting head to the position where you plan to start

- Position the job on the plate with a double click

- Verify engraving material

- Associated Power, velocity and Pulse parameters

- Thickness (important in case you do more than one passage)

- Color codes for engraving and cutting (check the panel to the left). Click update. If you see a warning about unidentified vectors, go back to you drawing tool and make sure that each object does have a good color (e.g. black for engraving). Inherited colors, in Inkscape for example, do not seem to work. Ungroup everything, select stuff to engrave and make sure that it has either stroke, fill or both.

- <Double click> on the workspace to bring up the Material library where you can change all parameters.

You also can change

- orientation of the work piece (

right-clickon the object) - orientation of the plate

Once the situation feels allright, click the Print button (lower right)

Establish Connectionin JobControl

- Verify

Exhaust Readyin Engraver Control (green arrow) in the Control of the JobControl

- Press

STARTbutton (green arrow) in Job Control.

Wait

- After printing slightly toxic materials, e.g. MDS (glues) or foam (styrene), wait at least a minute (until the aspiration ventilator stops). This will help keeping the lens clean and also help your breathing...

Preparation of drawing

Principles:

Input

- Any 2D CAD or drawing file.

- For cutting, the stroke of the vectors should be less than than 0.01mm (or 0.25pt), i.e. hairline of a same color. At TECFA, we use red for cutting.

- Other elements will be engraved, depending on the settings

- If you use the standard "Color mode" to identify objects, pick the colors from the limited set of the basic RGB colors.

Colorcode at TECFA:

- red = cutting

- black = engraving (simple or double, depending on the profile)

- blue = simple engraving

Software

We suggest creating all models in SVG. That way they can be displayed directly on the web. Most drawing programs can import/export SVG

(section to be moved some day)

Online tools

Process Options and parameters - Tables for cutting and engraving

Let's recall the basic principles. Engraving depth is varied through the laser power or the speed (energy per area unit principle) For cutting, Hz settings (pulses per second) should be set to low, in particular if materials are flammable. Vector lines are color coded and for each color one can assign a cutting/engraving parameter. I.e. one could use "red" for cutting" and "greys" for engraving. A print job can include cutting, or engraving, or both.

In addition to these basic parameters, one can define so-called "process options", i.e. instructions on how to create a print file.

- Process Mode will identify major algorithms used to transform a drawing into a "cuttable/engraveable" drawing

- There are various options that depend on selection of "Process Mode".

To learn more about parametrization, one could look at published examples, for example:

- Do it yourself samples (Trotec)

- laser_cutter (tags on thingiverse, but most include little instructions

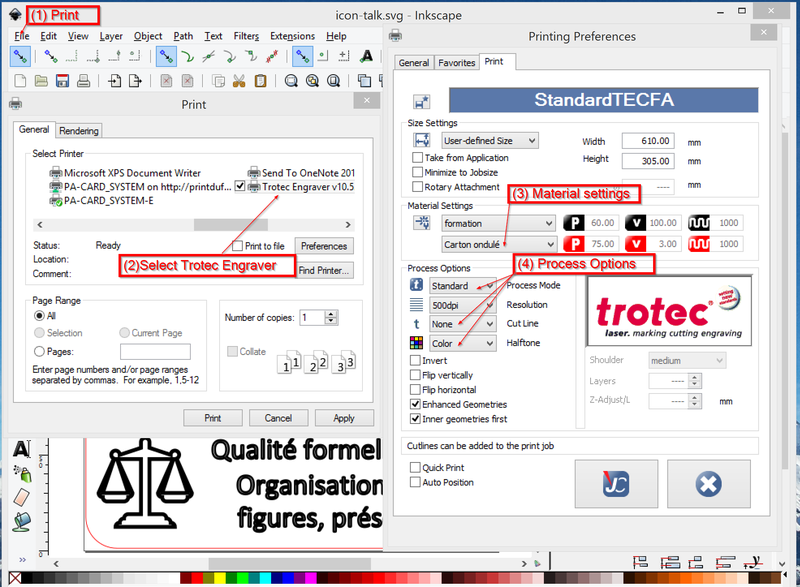

Process options are defined before printing. Here are the steps

(1) Step 1:

- From your application, e.g. Inkscape, Illustrator or PDF you will print your design.

(2) Step 2:

- From the Windows print menu select

Trotec Engraver Vxand then click onPreferences - In the Printing Preferences window, make sure that you are in expert mode (select the general tab)

(3) Steps 3 and 4: Define material settings and process options

In the Print tab you then must define the print process:

- Select <user defined size> in size settings and tick

minimize to job sizeand take from application. This way you can print several designs at the same time. If you leave the full dimensions (i.e. 600x300 you cannot). - Select

material settings(you can change these later again) - Define the

process options(these cannot be changed later, since the print driver must create the printable design)

More details are given below.

Process Mode

Process mode identifies the type of processing, i.e. how a drawing is interpreted and "translated" for laser cutting and printing

Standard

- Several design colors (at least two) will identify how a given object will be cut or engraved.

Stamp

- Is used to create rubber stamps.

Relief

- “This type of processing controls the laser power depending on the gray-scale value of the graphic.” <ref name="operationmanual">Trotec (2015), Operation Manual Trotec JobControl. Basic, Advanced, Expert. Retrieved from https://www.troteclaser.com/fileadmin/content/images/Contact_Support/Manuals/JobControl-Manual-EN.pdf, page 31</pref>

This configuration requires 256 gray scale (8-bit). Lighter means less power and darker means more power.

- white = no engraving

- black = full power

- levels of grey = depends.

Therefore one should use pictures or drawings with good contrast. Also, to see an effect, materials should be fairly soft so that the laser can remove enough materials in one pass.

Layer

- Layer is similar to relief but works with several passes. “Gray-scale graphics are engraved in several passes. The number of passes can be set in the range from 2 to 255” (page 31), i.e. each grey value is translated to a number of passes. This allow to create stronger reliefs.

Photo

- Allows to engrave high resolution pictures without prior vectorization.

Seal

- Allows creating seals.

Cut

- Same as standard mode, except that all non cutting objects are eliminated from the job before processing.

Other options

Engraving resolution

Resolution

- defines engraving resolution in dots/inch (DPI) e.g. in dots/2.54cm2.

- Recommended size is 500 in most cases. Going higher means much longer printing time and you won't see the difference with most materials. Higher also means increasing the engraving depth. As an alternative to high DPI, you also could engrave in two passes.

Cut line

None:Normal operation, i.e. cutting will only happend along your cut lines.Rectangular:Will create a cutting line that follows the job margins (is that the document size ?)Circular:Same as above, but will create a circleOptimize:Creates a cutting line that is ajusted to the contour of all engraving objects. Warning: Do not use "optimized" unless you need this. Cutting along the contour doesn't make sense, usually.

Automatically created cuttin lines (rectangular, circular and optimize) are always created in red. Therefore you also should make sur the "cutting color" is set to red.

Half tones

Halftone options will convert (or not) grey-scale or color images to black and white images. Various levels of grey or color "heat" is translated to different dot sizes and pitches that will still allow recognizing the original more complex picture. This process is called dithering (Wikipedia). Not available for relief and layer processing (since these require grey levels). There are three advanced dithering algorithms (Stucki, Jarivs and Floyd Steinberg). For more information about [ dithering], read Image Dithering: Eleven Algorithms and Source Code

ordered dithering

- Creates soft constrasts between brightness gradients

Stucki

- Probably the most advanced Dithering algorithm for photo engraving.

Jarvis

- Advanced Dithering algorithm for photo engraving

Floyd Steinberg

- The first well known advanced Dithering algorithm for photo engraving

Color

- Deactivites the halftoning, i.e. engravable objects will be engraved if they fit a engraving color defined in the Materials.

Black & White

- Will transform each pixel to either black or white according to a threshold level

Checkboxes

- We suggest ticking

enhanced geometriesandinnner geometriesfirst.

Material settings table

Since we just started with laser cutting, please consider the following very provisional ! In principle, the settings should work for a Trotec 50W CO laser... but they are by no means optimal (yet).

Often there are different solutions that lead to similar results. Remember that laser power received is a function of power and speed, and pulse (in case of cutting)

(Maybe outdated) profiles are in this web directory (selected groups)

| Material | Cutting power | Cutting speed | Cutting Hz | N cutting passes | Engraving power | Engraving speed | Engraving resolution | Notes |

|---|---|---|---|---|---|---|---|---|

| MDF 5mm | 55 | 1.1 | 1000 | 2 | 50 | 100 | 500 | 2 passes reduced burning |

| MDF 3mm | 80 | 1 | 1000 | 1 | 50 | 100 | 500 | |

| Plywood birch 4mm | 100 | 1.3 | 1000 | 1 | 80 (ou 2x à 50) | 100 | 500 | Attention aux flammes |

| Plywood birch 6.5mm | 80 | 0.5 | 1000 | 2 | 60 (2x) | 70 | 500 | Double passage. Result is very black and requires washing. You could put some painters tape on the cut lines to avoid blackening of the surface. Also try triple passage. |

| Plywood birch 6.5mm (variant) | 100 | 0.6 | 5000 | 2 | 80 | 70 | 500 | Result is very black and needs washing. More pulse doesn't change that much. Result looks similar and flames are a bit bigger and will destroy thin elements. |

| Plexi 4mm | 100 | 0.8 | 4000 | 1 | 80 | 100 | 500 | Position the plate on top of some wooden blocks, not directly on the grid. |

| Plexi 3mm | 100 | 1 | 4000 | 1 | 80 | 100 | 500 | |

| Plexi 2mm | 100 | 1.2 | 4000 | 1 | 80 | 100 | 500 | |

| Ondulated Cardboard | 75 | 3 | 1000 | 1 | 60 | 100 | 1000 | Rough settings, thickness and density is widely different. If the first layer is thicker you can go with engraving P = 80 |

| Thick paper 0.25mm ? | 30 | 3 | 1000 | 1 | 80 | 100 | 1000 | |

| Cotton (pants) | 30 | 3 | 1000 | 1 | 90 | 100 | 1000 | Test this, engraving effects differ for each type of cotton. I made a Halloween mask from a cut off pant leg) |

| Wood Wine box 7mm | 100 | 1.5 | 1000 | 2 | 60 | 70 | 500 | |

| Anodized aluminum, e.g. Laptops (this needs to be tested !) | - | - | - | - | 100 ? | 100 | 500 | Not tested, probably also depends a lot on the coating. Use weaker settings for plastic cases !! |

| Material |

Notes on materials

A small CO2 laser cutter can cut or engrave a wide variety of materials, e.g. (some) plastics, wood, cardstock, textiles, cork, Delrin, Depron foam.

Never cut anything that includes chlorine. Its gas can badly damage your lungs and the machine. Without ventilation it even could kill. Other materials like ABS or HDPE can catch fire and/or melt.

Read more:

- Laser Cutter Materials (Hackerspace).

- Universal Laser Cutter Tutorial (MIT). Just read the intro.

Acrylic (plexi)

Acrylic, better known as Plexiglas and also known as Plexi, or Perspex is probably the easiest material for cutting. There are two different types of Plexiglas – cast and extruded. Cast acrylic seems to work better.

It is best to place the sheet on some pieces of wood as opposed to directly putting it on the honeycomb (i.e. there will be less reflection that could cause little damages to the plexi).

- Chemical name: PMMA, (in french): polyméthacrylate de méthyle

Cast acrylic (Plexiglas GS)

- Presents a nicer surface

- Cutting is more precise

- becomes white or mat after engraving, i.e. you get a better contrast

Extruded acrylic (Plexiglas XT)

- is cheaper

- remains clear

- doesn't cut as nicely and sometimes even badly.

In other words, extruded Plexiglas is cheaper but results (both for cutting and engraving) are not great.

Cardstock, cardboard and paper

All cut well and engrave well enough.

- Cardstock is "thick paper", e.g. like birthday greeting cards.

- Ondulated carboard a very good prototyping material, since it is free (you always can find shipping boxes that you can tear apart) and it has a similar thickness as poplar plexiglass and plywook width (i.e. about 3mm). Make sure to use less power for cutting and single pass engraving or there could be a risk of fire. In any case, ventilation should be on.

- Thick paper that one can use with a laser or inkject printer can be engraved and cut. Cutting power should be low and engraving power rather high.

Engineered composite wood

Various variants of "engineered woods" are popular materials in education, since it they cheap and stable. However, they contains glue and other ingredients and may not cut as nicely as solid (non resinous) wood. In addition, these components may represent a health risk.

MDF (Medium density fiberboard)

According to Wikipedia (10/2016), “edium-density fibreboard (MDF) is an engineered wood product made by breaking down hardwood or softwood residuals into wood fibres, often in a defibrator, combining it with wax and a resin binder, and forming panels by applying high temperature and pressure. MDF is generally denser than plywood.”

There exist variants. Again, according to Wikipedia, MDF is typically made up of 82% wood fibre, 9% urea-formaldehyde resin glue, 8% water and 1% paraffin wax and the density is typically between 500 kg/m3 and 1,000 kg/m3.

High-density fiberboard

High-density fiberboard (HDF), also called "hardboard" is, according to Wikipedia (10/2016) similar to particle board and medium-density fiberboard, but is denser and much stronger and harder because it is made out of exploded wood fibers that have been highly compressed. Consequently, the density of hardboard is at least 500 kg/m³ and is usually about 800–1040 kg/m³. It is used in the furniture industry and construction.

HDF works well with laser cutters

Plywood

Plywood (contreplaqué in French and Sperrholz in German) includes at least three rotated layers of wood. Plywood boards are cheaper to produce than wood and keep their form. However, unlike wood, it is difficult to sand plywood to make it look again once it starts aging. According to Wikipedia (10/2016), Plywood is a sheet material manufactured from thin layers or "plies" of wood veneer that are glued together with adjacent layers having their wood grain rotated up to 90 degrees to one another.

There exist many different types, e.g.

- Softwood plywood, typically used for construction

- Hardwood plywood “is made out of wood from angiosperm trees and used for demanding end uses. Hardwood plywood is characterized by its excellent strength, stiffness and resistance to creep.” (Wikipedia)

- Aircraft (or high-strengh) plywood is usually made from mahogany and/or birch.

For laser cutting, there are three challenges:

- Avoiding defects (e.g. hard nodes) in the inner layers

- Cut a larger sheet in a single passage (smaller lasers like ours cannot do that) and avoid too much "burning". Good quality plywood (e.g. birch) seems to be hard to cut (much harder than wood from wine boxes or MDF)

- dealing with (sometimes) rather toxic glue.

Usually, more layers (multi-ply) wood means better quality. According to the nervous system blog, multiple layers may include more opportunities for "bad" spots to exist and contain more glue and therefore are not more suitable for laser cutting. As result they decided to have their own three layer version built from high quality wood.

There are companies that sell plywood designed specifically for lasering.

Foams

Various foams can be cut, but tend to melt and produce somewhat toxic gases. Special safety measures must be taken (ventilation on) and the lens should be cleaned after each job.

According to Trotec (10/2016), Foams made of polyester (PES), polyethylene (PE) or polyurethane (PUR) or Neopren® are well suited for laser cutting, laser engraving and laser marking. (in french: polyester (PES), polyéthylène (PE) ou polyuréthane (PUR) ou Neopren®)

Polyester

Polyester are mostly used for clothing, but some kinds of foams also seem to exist...

Polyurethane (PU)

Is the kind of foam that one can find in packaging and matresses. Typical brand names are: PUR, PU, Cellasto®, Elastocoat®, Elastoflex®, Elastofoam®, Elastolit®, Elastopal®, Elastopan®, Elastopor®, Lupranol®, Baydur®, Bayfill®, Bayflex®, Baylit®, Baymer®, Baytherm®, Desmodur® (according to Eurolaser)

Different densities exist (measured in kg/m3) and the material is rather cheap. E.g. on Amazon.fr 200x60x3 14kg/m3 white is 6 Euros on Amazon.fr. Denser material is a bit more expensive, e.g. 200x120x3 is 16)

Polystyrene (PS)

Foams made from Polystyrenes are mostly semi-ridid, i.e. use in architectural models or publicity. Seems to be very inflammable

Some brand names are PS, Hostyren®, Vestyron®, Styropor®, Hostapor®, Vestypor®, SMART-X®, Elmer.

For example: Elmers is sold in carft stores and online, e.g. here. Elmers foam is probably OK if you have a good ventilation system. It does not contain chlorine, see the MSDS

Polyethylene

Seems to melt a lot.

To sort out

- Adams

- DTFB

Cloth

Most "natural" fibers like felt, hemp or cotton cut well.

Warning there is a danger that the print head will grab some piece of floating textile and then displace the whole thing (remember 3D printing). To avoid that, make sure that the cloth is very flat, e.g. wrap it around a sheet of metal or even better tape it down with some double sided tape.

Some synthetic fibers also do well, but be very careful (in particular never use dangerous PVC/Vinyl)

Engraving is a bit more tricky. Fleece or felt jackets are probably best. For these, try 100% and 100% speed. Doing thinner materials without cutting out too much is difficult. Maybe use two passages with lower power ?

Anyhow, cutting and engraving textiles is fun, but always try first with a same or very similar material before you thread your new blue jeans...

polyvinyl chloride (PVC)

According to Wikipedia, The terms "PVC", "vinyl" and "PU" tend to be used interchangeably by retailers for clothing made from shiny plastic-coated fabrics. These fabrics usually consist of a backing woven from polyester fibers with a surface coating of shiny plastic. The plastic layer itself is typically a blend of PVC and polyurethane (PU), with 100% PVC producing a stiff fabric with a glossy shine and 100% PU producing a stretchy fabric with a silky shine. A manufacturer's label may say, for example, 67% polyester, 33% polyurethane for a fabric that contains no PVC; or 80% polyvinyl chloride, 20% polyurethane with mention of the polyester backing omitted. To add to the confusion, the plastic layer is often textured to look like leather ("leatherlook", "pleather"), as opposed to smooth ("wetlook", "patent").

- Very dangerous. It will both damage the laser (e.g. the lens) and your lungs. You will have to particularly careful with unlabelled textiles. Do never use Vinyl sheets made for the cutting plotter.

Links

Models

Various tutorials and other useful texts

- Laser tutorial (EPFL, for a trotec speedy 500)

Local (Geneva area) shops for materials to cut

- Migros Materials (local do-it-yourself shop)

- Wood and Plexi XT

- e.g. verre acrylique (500 x 250 x 5 = CHF 12.90)

- Polyplast

- Route des Acacias 11

- Plexi

- E.g. Plexiglass

- Elega

- E.g. Plexiglass

- Antalis

- https://www.antalis.ch

- E.g. Visacry (Plexi coulé CHF 71 / m2 5mm

- Serex

- E.g. PLEXIGLAS XT, CHF 50 / m2 3mm and CHF 83 / m2 for 5mm