Lego-compatible thesis project board

<pageby nominor="false" comments="false"/>

Introduction

I designed the thesis project board as a physical visualization tool that will help folks with both planning and monitoring a Master or PHD thesis. It also is a social tool, i.e. on display in an office or a living room it will show others where your are.

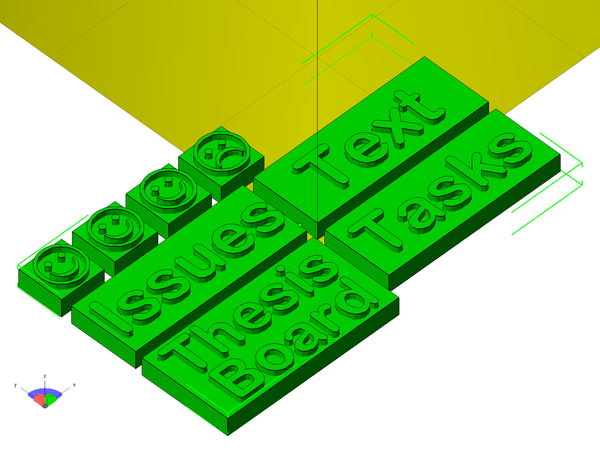

The thesis project board has three components:

1. A task list (made of lettered Lego bricks) that should include all major tasks, such as getting in a program, finding an adviser and an advisory board, writing the research plan and having it accepted, literature review, data collection, data analysis, requirements, development, etc. Configuration of this list depends on the field, the nature of the thesis and the institution.

2. An issue list - again made with lettered Lego bricks - that should include each major problem that pops up or that is known right from the start. For example: lacking skills (e.g. in data analysis or programming), writer's block, tendency to procastinate, time left after getting other important work done, doubts about the future, access to data, difficult advisors, ....

3. A text list that simply lists the various chapters.

Monitoring chapter writing and the task list are different views of the "problem" although some items strongly correlate. E.g. the literature review could start in the thesis project plan, in a wiki and then be spread out over chapters 1-3.

Each list is built with special-purpose lettered Lego bricks. Print the ones that you need. Next to each item the candidate then should build towers using standard bricks and that represent its state. Next to both task and chapter items, there is a slot for a 2x2 column that will measure advancement. I suggest to use 5 standard 2x2 blocks, each representing 20%. Once you reached 100%, these towers can be replaced by a special "smilie" tower. The issue items are associated with two columns, one that measures severeness and the other progress (problem resolution).

Bricks could be printed with different colors according to type. Lego blocks that represent advanced can use any color, but monochrome is nicer. Since Legos are very expensive, you may try to buy these from second hand stores or on online web sites. Of course, you also could print these, but that takes time.

Current status, questions and plans

Current version

This is version 1.x. So far, I didn't test it, but I will do that with local PHD students. However, that can take years :)

However, I'd be extremely glad to receive any sort of comments and suggestions, even little ones such as missing bricks.

Questions

1) I tried to figure out a "good size". The board should be both visible and at the same time not take up too much space. I.e. a person should find space on his/her desk.

2) There are not enough task and issue bricks. Which ones are missing ?

3) Bricks are fairly ugly. Is there a way to do better ? I also am aware that lettering is pretty ugly using 0.25 layers, maybe I should try other fonts. Designing lots of meaningful 3D icons is beyond my skills. Input with respect to that also would be welcome.

4) Is the three lists design (tasks, issues and chapters) ok, or is there some fundamental category I missed.

5) How high should the towers be. I believe 5 x a standard brick height should be ok. 10% steps could be displayed with 2x1 bricks

6) Should there be a repository for bricks ? E.g. a big wall around the board or a specially designed area. I am afraid the people will not keep/find a bad with enough Legos nearby...

7) Is it really necessary to design a custom board that takes time to print ? A standard Lego board could be the favorite solution. That's what one of our PhD students told me after showing him the two on day two of printing....

8) Should I create a DUPLO version of the bricks ? Would take much more space, but the lettering would be much nicer and I could even add some icons.

9) I should expand this idea for managing other projects, e.g. research projects or development and design projects. This also would imply that I should figure out how to visualize [[1]] ways of planning.

10) I should create a 3D structure for hosting the bricks, e.g. with some sort of stackable objects like in the castle kits. This would save office space ...

Board plates

Variant 0

Don't print anything at all.

- Buy a Lego board (like the blue one below)

- Buy flat smooth pieces and label these with a felt pen. Such sets can be found on amazon.de for example. Search terms:

- "Lego Fliesen" (german) ... On Amazon.de, several hits. A few have good size

- "Smooth Lego tile" (US) ... there was only one hit on Amazon.com

variant 1

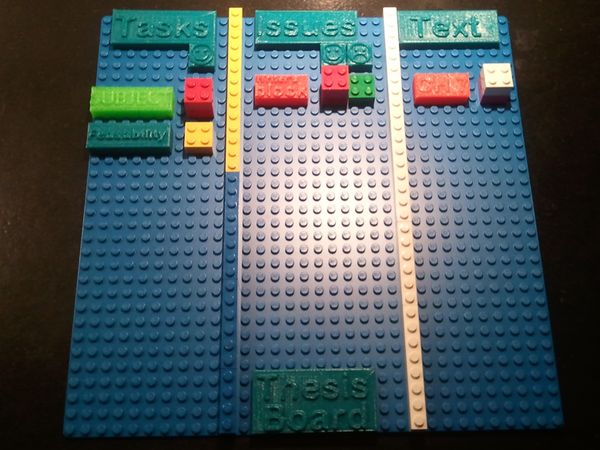

Buy a Lego board and configure it like in the picture that shows a blue plate. I.e. print all bricks that start with "board" to make it look like a thesis project board. So far, after 2 weeks of initial user feedback, this seems to be the best solution since it allow user to be creative and to get engaged in some play that could help some sort of "bonding" to this tool.

variant 2

Uses a neat (sorry) just the right size for you desk. Time-consuming to print and impossible (I'd say) on non-PLA capable printers. Inhibits play which may be a good reason for not using this.

Below is my first print together with a first version of tasks, issues and chapter blocks

The next picture shows a slightly bigger one, printed with a less threatening color

Note: Chapter blocks are uglier than usual in this picture since the blocks were at Z=0.5mm and the letters were stuck in the top floor of the block. Took me some time to figure this one out since Repetier host just drops the pieces down.

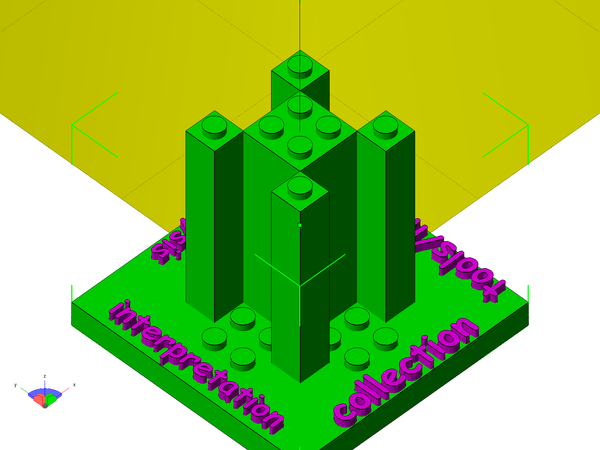

Variant 3

is true 3D, i.e. a series of stackable towers, each representing a task or issues area. However, it will take me some time to figure out stuff that makes sense. Stay tuned - Daniel K. Schneider 13:58, 25 October 2012 (CEST)

The following tower_data_1 would be still too much 2D, but may nevertheless be a trail to pursue:

Variant 3b

The next item is a configurable variant called tower_central

Variant 3c

The next item is a combination of a general purpose tower that can held 4 slots and a fixed removable cover. You are done after filling each column. Btw, the example is about a 3D printing project like this one and not about a thesis. It could represent its R&D part though.

Variant 4

The next item is a tower that can host task bricks in front.

- Progress then is indicated by tiling. Once you got a smooth floor you are done with a task.

- These towers can be stacked

- On top you can put a nice roof so that people know what it is good for.

Below is picture of the first print (printed at fairly high speed)

New variant/version ideas

Under brainstorming.

1) I am thinking about creating a tree. I.e. something that can grow upwards with branches and "leafs". Each leaf then would represent an element (task, problem, etc.) and space for adding progress/problem indicators. DUPLO has such elements if I recall right.

2) A SCRUM-like board or structure

3) More space for play !!

User testing

User 1

Subject: PhD student in an earlier stage of thesis (project accepted by thesis commission)

User 1 went through several stages. Below we just summarize some elements:

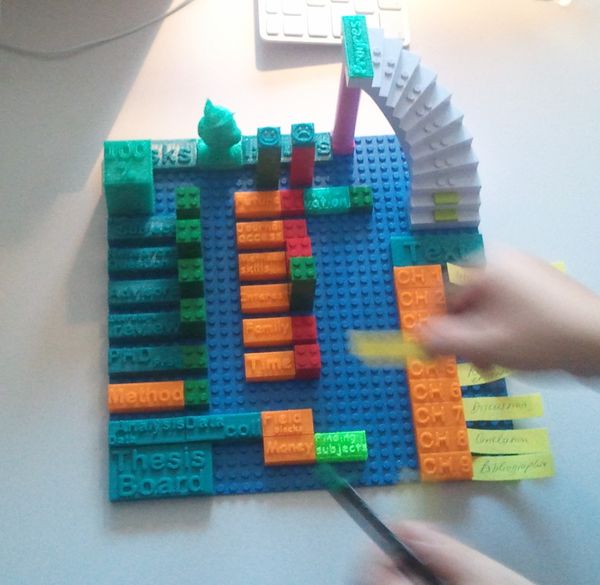

Stages (so far, nov 22 2012)

- Used the project board

- Used a bigger standard Lego board in order to regroup, add extra handwritten bricks, add progress stairs.

- Use a still bigger standard Lego board in order to create connections, add "stories", etc.

We define stage as a major shift. Within each stage, there have been variations

Stage 2

- nov 19 2012

- Includes labeling of chapters

- Adds a general progress indicator (stairs brought in from home)

- Identifies more issues

- Adds "play" bricks

- Two other PHD students want one

Stage 3

- nov 22

- Adds connectors (the arcs) visualizing how a task and an issue and 2 issues are connected

- Uses extra bricks (e.g. a gate-in)

- Adds persona (thesis advisor, kids, ...)

- Identifies yet more issues

- Layout is often changed/updated (sometimes several times per day)

Stage 3b

- This layout starts attracting other users for play. On 11/29 a colleague moved up the persona on the stairs.

Stage 4

In the cloud. User feels that the project doesn't advance enough.

Focus on essential issues:

User 2

Subject: PhD student in an earlier stage of thesis (project accepted by thesis commission). Some literature review and development done.

User 2 shares office with user 1 and immediately wanted to work with a large board.

Stage 1

- Separated issues into two different kinds (these related and external/others)

- Associated chapter bricks with task bricks

The following pictures show a prototype after a few minutes into the "game"

Bricks

Task bricks

12 so far, let me know if you need others.

Issue bricks

9 so far, let me know if you need others.

Below, some pictures of items that can become problems....

Chapter bricks

9 so far. That should be enough. Keep the size of your thesis down. Your advisors and jury will be grateful.

Buying 2x2 and smooth Legos

Since you will need lots of 2x2 Legos for the progress indicators, I suggest that you search on the Internet for packs. I suggest Amazon.de (not .com or .fr or co.uk). The same is true for the "version 0", i.e. write with a pen on smooth pieces.

Amazon.de has resellers that will provide these in packs of 50 for about 9 Euros. In particular, "Wichtel10000" has a few million bricks in his inventory and you can make personal enquiries, e.g. he got lots of 2x2 standard bricks and 4x2 smooth bricks (email exchange, dated oct. 25 2012).

Amazon.com sells 100 blocks for $19

Search terms:

- German: "2x2 noppen" Lego

- English: lego "2x2 bricks"

Getting it

Download

Download from Thingiverse:

File names

I only included a subset of bricks as single STLs for now. However:

- STL.zip contains all the blocks

- STL-sets.zip include multiple bricks for printing (difficult)

- source.zip contains all the source, including netfabb files and openscad code

Printing tips

General

Printing Lego bricks is a bit more difficult than it may seem.

- You do need a 0.25mm layer-capable printer, and that it includes corresponding x/y precision

- The first layer must stick to the print bed. Therefore it must be totally flat and aligned with the nozzle. In addition, the nozzle must be close (1 sheet of paper)

- Printing with ABS probably requires a heated print bed since the walls will try to warp upwards. A heated print-bed is better for PLA printing too.

- The bottom side of the roofs will likely be ugly and there is not much I could do (except creating a design that doesn't look like Lego bricks)

- Turn the fan off while printing the platform until the first layer of the roof is done. Any hard little piece that sticks out can cause the nozzle to become stuck a bit and then rip off something or displace the next layer. Printing platforms is a challenge, only attempt if your filament is high quality and printer has a really flat and well calibrated printbed.

Slicer settings

- First layer must be real slow: 12 mm/s

- 0.25 layers or less for better quality

- Other layers: 40 mm/s or much higher for less good quality

You may use manual overrides for printing walls (you can go fast there) and then slow down again for the lettering and nibbles.

If you want to produce nice letters:

- Use 0.1 layers. If your slicer can do half layers in certain regions (e.g. Netfabb) use this feature. In Skeinforge and SFACT, I suggest using 0.25 layers and the use SKIN (1/2 horizontal and vertical layers).

- With 0.25 layers, letters are readable, but not as pretty ...

Fit

Calibrating OpenScad (or any CAD model of course) for the right fit is a nightmare. Nibble, inset and wall sizes depend on many parameters like: Layer size (obvious), spread, Type of plastic (black PLA is fatter than transparent PLA), print speed (believe me), etc.

The only way to get it right is to print a simple 2x4, then adjust parameters in OpenScad and generate all the blocks again. Use the source.zip for that. An anecdote: The black board (version 1, see above) has perfect fit. The orange one (version 2, see above) is a bit loose. The only difference in slicer settings was fill and anti-stringing. Both were printed at same speed (0.25 layers, 80mm/s for the fills and 35 for the perimeters). The orange had a bit less retraction (i.e. result should be worse but wasn't) and 35% fill as opposed to more standard 25% fill. In other words, the black probably one has better fit since lower fill produces worse quality of roofs. There also could be some difference in the plastic that creates sloppier results. Btw. the orange board took about 9h to print.

Problems

- Ugly overhangs underneath the lego roofs: ignore

- Bumps when printing the roof of the big base plate: Slow down and turn off the fan until it looks flat again. This also can happen in the first layer after printing the little squares. Anyhow I suggest printing flat structures without fan. If there is something sticking out, the nozzle will slide through if the plastic is still somewhat warm...

- Little squares or Lego nibbles not sticking to the first layer: Nozzle must be real close in every location, slow down, heat up. Repair strategy if one comes loose. Instead of aborting a print, you can attempt to glue it back, e.g. put the thing in position and use a blow torch directly on the print bed (if it is made of metal !). Removing the piece, heating it and putting it back doesn't work as well. Tip: Kapton tape easily can take heat.

- Ugly lettering: reduce speed and/or reduce layer height (or work with half-layers if your slicer let's you define regions)

- Unexplained no "filament comes out": Check your filament. If it is too thin in places it will hate the frequent retractions that a typical slicer configuration will create for Legos. You also can reduce anti-stringing/oozing measures. Strings don't matter in this project. Just burn them away. If the filament is too thick in some places (e.g. 2.1mm instead of 1.75 or 3.5 instead of 3, buy new filament.

In the picture above with the black board you can see really ugly chapter bricks. These are explained by the fact that I changed a piece in the z-axis and I forgot to place a bolt in the right place. Anyhow, printing perfect lettering with 0.25 layer-width won't work. But I just hate waiting for too long and also printing with 0.1 layers creates other problems, in particular with roofs.

Printing batches

I never managed to print larger batches correctly and get two issues

(1) Some blocks can warp sometimes. I don't understand why since I can print larger surfaces on the printer without warping. Maybe the print head banging a tiny bit into bricks ? Maybe some dirt in the area. I just don't know

(2) 1-2 Lego cylinders may come off after the first few layers

There are 3 solutions

- Ignore, but the risk is that this could propagate, i.e. the whole brick can be ripped away

- Restart

- Add a patch. Instead of throwing away print aborts, keep these. Then when a cylinder gets ripped off, take it away. Add a some square piece of about the same height in the area, then with a blow torch melt it to the platform.

Do it yourself

Creating different boards

Start from the openscad files to generate your own boards. Use Netfabb or some other software for on-board lettering.

Lettering on top of blank blocks

Use netfabb files for lettering. Read the Netfabb Studio tutorial

Download a block or generate one with OpenScad. (http://www.thingiverse.com/thing:33001 - File STL.zip)

Lettering can be done with other software, but I found Netfabb to be the easiest tool. However, if you don't own the expensive Studio version, you will have to proceed in the following way in order to get a single printable STL:

- Load an appropriate flat lego brick into netfabb. Found in the directory STL/blank_bricks

- Do the lettering: Use 72pts and about 10mm height and 2mm depth

- Position the lettering in the right place. To adjust x/x, make sure to position the camera in "Top View". Then use the positioning popup for the Z-axis, e.g. move it up by 9.6mm.

- Adjust dimensions, Make sure to keep Z as is.

- Export the lettering (1 or 2 STLs)

- Import all these STLs to Meshlab

- Import all the meshes (block and letterings): Menu file->Import Mesh

- (Do not attempt to position anything with Meshlab. It's too hard. Use Netfabb)

- Menu Filters->Layer and Attribute Management->Flatten Visible Layers

- File->Export Mesh as

Again, read Netfabb Studio tutorial for some introduction. You also can have a look at Meshlab for RapMan tutorial

Post processing

The most important tools you need are in that order: A mini gaz torch, a flat file and a heat gun. Read Post processing of 3D polymer prints for details.

- Blow away little strings with the torch, but stay away and flame quickly ! I strongly suggest to use the protection since it will direct the heat also make sure that you keep some distance.

- If some corners or roofs stick out, you can file these. After that, use the flamer again to restore good looks.

- If fit is a problem, heat the piece underneath with either the flamer or (better) the heat gun (around 120 degrees C for PLA). Then, gently (!) press it down on the board.

Links

EduTechWiki links

- Category:3D printing Several technical pieces, including tutorials

- Methodology tutorial for social sciences

Using Lego in project management and similar

- Lego reflections by By Sarah], March 7, 2009

- The Amazing and Versatile Multipurpose Innovation Tool (some sort of kit for gaming)

- Project management classes taught at HES Yverdon (need a paper here).

- How GM Is Saving Cash Using Legos As A Data Viz Tool by Mark Wilson (undated, retrieved oct 2012). See also the comments that people added...

A very different perspective is to use lego building as substrate for team building, management, etc. E.g.:

- McCrindle, R., 2010. Software engineering –engagement through innovative and interaction. Higher Education Academy, Engineering Subject Centre, Teaching Award 2010