InkStitch - embroidery patch: Difference between revisions

mNo edit summary |

mNo edit summary |

||

| Line 21: | Line 21: | ||

== Introduction == | == Introduction == | ||

Creating a patch with only an embroidery machine | This little tutorial explains how to design embroidery patches with the free and open source [[InkStitch|Ink/Stitch]] software | ||

Creating a patch with only an embroidery machine requires a little bit of precision work. | |||

Creating patches is explained in general terms in the [[Embroidery patch]] article. Here, we just summarize | Creating patches is explained in general terms in the [[Embroidery patch]] article. Here, we just summarize the method we like best. | ||

=== Prepare the fabric === | === Prepare the fabric === | ||

Cut out some fabric of the size of the badge. You can print out a paper version of the design and use it as model. | Cut out some appropriate stable fabric of the size of the badge. You can print out a paper version of the design and use it as model. | ||

Ideally, you could cut the patches with a laser cutter. We use our [[Trotec Speedy 100R]] 50Mw with settings: power=23, speed=1.9 and Hz=1000. Since the fabric may warp consider weighting down the borders, e.g. with pieces of lead. | Ideally, you could cut the patches with a laser cutter. We use our [[Trotec Speedy 100R]] 50Mw with settings: power=23, speed=1.9 and Hz=1000. Since the fabric may warp consider weighting down the borders, e.g. with pieces of lead. Scissors will also do, but try to be as precise as possible. | ||

[[File:Laser-cutting-textured-fabric-for-embroidery-patches.jpg|600px|none|thumb|Cutting fabric for embroidery patches]] | [[File:Laser-cutting-textured-fabric-for-embroidery-patches.jpg|600px|none|thumb|Cutting fabric for embroidery patches]] | ||

| Line 47: | Line 48: | ||

* Stitch a placement stitch (cut line) that has the size of the patch. | * Stitch a placement stitch (cut line) that has the size of the patch. | ||

* Remove the hoop | * Remove the hoop | ||

* Stick the | * Stick the pre-cut fabric inside/on top of the cut line. (If you don't have a sticky stabilizer, glue the fabric) | ||

* Put the hoop back | * Put the hoop back | ||

=== Tack down and stitch the border === | === Tack down and stitch the border === | ||

* Stitch an optional | |||

* Stitch an optional tack down stitch followed by a zig-zag border first. The zig-zag's underlay will do as tack down. | |||

[[File:brother-patch-8mm.jpg|600px|none|thumb|Stitching an embroidery path in progress]] | [[File:brother-patch-8mm.jpg|600px|none|thumb|Stitching an embroidery path in progress]] | ||

Revision as of 00:20, 20 July 2018

Introduction

This little tutorial explains how to design embroidery patches with the free and open source Ink/Stitch software Creating a patch with only an embroidery machine requires a little bit of precision work.

Creating patches is explained in general terms in the Embroidery patch article. Here, we just summarize the method we like best.

Prepare the fabric

Cut out some appropriate stable fabric of the size of the badge. You can print out a paper version of the design and use it as model.

Ideally, you could cut the patches with a laser cutter. We use our Trotec Speedy 100R 50Mw with settings: power=23, speed=1.9 and Hz=1000. Since the fabric may warp consider weighting down the borders, e.g. with pieces of lead. Scissors will also do, but try to be as precise as possible.

Hooping

- Hoop a self-adhesive tear-away stabilizer, sticky side up.

- Consider using two layers to add some extra stability

Yes. Do not attach the stabilizer to the fabric.

Alternatively, for better results, you could use a heavy water-soluble or heat-soluble stabilizer. But then you'd have to rehoop after each patch...

Place the fabric

- Stitch a placement stitch (cut line) that has the size of the patch.

- Remove the hoop

- Stick the pre-cut fabric inside/on top of the cut line. (If you don't have a sticky stabilizer, glue the fabric)

- Put the hoop back

Tack down and stitch the border

- Stitch an optional tack down stitch followed by a zig-zag border first. The zig-zag's underlay will do as tack down.

Stitch the rest

Then stitch the rest of the embroidery.

Reuse the stabilizer in the hoop

Carefully remove the patch. It should "come off" very easily since the sating border will have perforated the stabilizer.

You now can just stick a piece of stabilizer on top of the round hole (sticky side up!) and start again without re-hooping.

If this is well done this will last for at least 10 patches.

It is probably best not to stitch a background color. Otherwise you will have to manage a pull/push effect and also make sure that the overlap between border and background looks good. The zigzag stitch should come first in order to make sure that it is correctly placed along the borders. Instead, use specialized fabrics for batches that look good, e.g. Twilly or Step from Gunold.

Glue the patch onto some cloth

In our very limited experience, the easiest way of gluing a patch to some cloth is to us some thermo film made of glue. Again, Gunold does have several products. We have HeatnBond Lite.

(1) Cut a piece of thermofilm, a bit bigger than the size of the patch

(2) Infuse the patch with glue

- Put the patch upside down in a heat press or on a table

- Put thermofilm on top, cooking paper on top. If it doesn't have its own cooking paper add your own.

- Heat with a heat press or an iron for about 3 seconds

- Remove the cooking paper

The patch now has glue on the down side. Alternatively, you can cut a larger piece of thermo film glue. Apply it is as shortly as possible (about 2 seconds) to the backside of the patch, then cut it.

(3) Apply the patch to the cloth

- Put the patch on top of the fabric.

- Again, put some cooking paper on top

- Heat for 5-10 seconds

(4) Sew the borders. Otherwise the patch might come off during washing.

Templates

Below are two 6.1cm templates with rather narrow zigzag borders and a 8cm one. You will have to put something inside

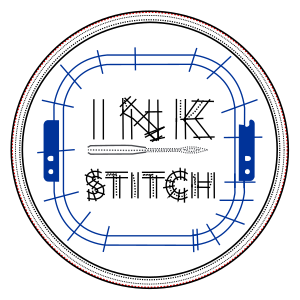

InkStitch example

The following design is available from the Ink/Stitch web site. It nearly fits into the rather large 80mm patch. We just reduced it a little bit. We had to modify the design for the smaller 6.15 version, i.e. replace satin stitches in the needles by straight lines and remove some density.

6.15cm Version 1

This design has quite a lot of pull. One probably could make the blue frame a bit smaller and use less density. The border may have to be improved (less underlay) and the placement stitch made a bit bigger. The hooping probably wasn't perfect. We should have used two layers of stabilizer.

6.15cm Version 2

8cm Version 1

Of course, you are not really obliged to use the official colors.

Copyright modification

Contents of this page including pictures and SVG files are also available under the GNU Free Documentation License and the Attribution 4.0 International (CC BY 4.0) license.

The Inkstitch project can use any element (text fragments, SVG files, pictures) for the project's official docs without giving attribution (just copy and paste).