Skeinforge for RapMan: Difference between revisions

| Line 267: | Line 267: | ||

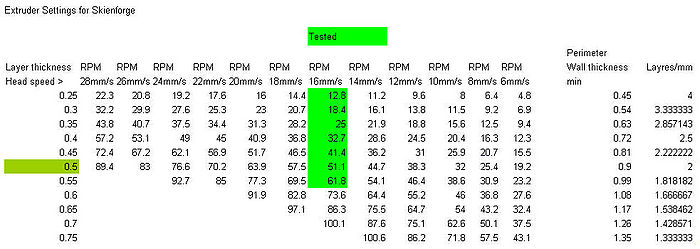

In the [http://rapmanv3.blogspot.com/2009/09/more-skienforge.html Rapman blog] (written on 25 September 2009, retrieved 20:59, 11 March 2010 (UTC)) there is an interesting table that shows the ''theorectial'' relationship between Head speed, Extrusion Rate and Layer thickness. | In the [http://rapmanv3.blogspot.com/2009/09/more-skienforge.html Rapman blog] (written on 25 September 2009, retrieved 20:59, 11 March 2010 (UTC)) there is an interesting table that shows the ''theorectial'' relationship between Head speed, Extrusion Rate and Layer thickness. | ||

[[image:skeinforge-table.jpg|thumb| | [[image:skeinforge-table.jpg|thumb|700px|none|Head speed, Extrusion Rate and Layer thickness table]] | ||

{{quotation|If you want a layer thickness of 0.35 (first column) at a head speed of 16mm per second (7th column)you would set RPM to 25, the perimeter wall thickness will be 0.63 (13th column) and there will be 2.857143 layers per mm height (14th column)}} ([http://www.bitsfrombytes.com/fora/user/index.php?topic=561.msg5139#msg5139 David White]) | {{quotation|If you want a layer thickness of 0.35 (first column) at a head speed of 16mm per second (7th column)you would set RPM to 25, the perimeter wall thickness will be 0.63 (13th column) and there will be 2.857143 layers per mm height (14th column)}} ([http://www.bitsfrombytes.com/fora/user/index.php?topic=561.msg5139#msg5139 David White]) | ||

[[image:skeinforge-table2.jpg|thumb|600px| Extrusion Rate and Layer thickness table]] | [[image:skeinforge-table2.jpg|thumb|600px|none|Extrusion Rate and Layer thickness table annotated by D. White]] | ||

Note: RPMs in skeinforge / g-code are multiplied by 10. E.g. 25RPM ''is'' 250.0. | Note: RPMs in skeinforge / g-code are multiplied by 10. E.g. 25RPM ''is'' 250.0. | ||

Revision as of 22:02, 11 March 2010

Some mission critical stuff may be missing or wrong. I am just learning. Always check the generated g-code too. - Daniel K. Schneider 11 March 2010.

Introduction

Skeinforge is a tool chain for printing 3D objects.

The purpose of this entry is twofold

- Help beginners use skeinforge

- Write down the most important parameters and settings for the RapMan V3.1 (as built

at TECFA, each Rapman may be a different).

Otherwise / in addition:

- Click on the ? bottom of the skeinforge screen. This will load an html page with lots of pointers into your browser.

- In particular, read the "official" Skeinforge article on BFB wiki. However, the BFB entries do not correspond to the organization and parameter names of the latest software version at the time of writing (11:11, 11 March 2010 (UTC)).

- See the links section at the end.

First steps

(1) Make sure that your printer is calibrated as it should

- Flat print bed

- You can slide about 5 sheets of paper between the print head and the print bed. If the print head (hot end) is too high, forget it ...

(2) Download the latest version

- Download: Skeinforge

- Download: Python (if needed)

- Unzip skeinforge.zip in some simple directory, e.g. c:\soft\

- Make a shortcut of the *.py file on your desktop if you like (mouse-right drag under windows)

(3) Then fix all the parameters as described below, at least the temperatures. To not forget to select the right profile (e.g. extrusion/ABS) and to Save All your changes.

(4) To create g-code, click on the "Skeinforge button" (lower left) and select your something.STL file. A file called something_export.gcode will be created. Rename it to something shorter, e.g. some_1.bfb (the RapMan board wants old MS-DOS type of file names and extensions).

Tips:

- Before printing with the RapMan, heat it up with the tool setup to a high temp (e.g. 248 degrees for ABS), then extrude about 50cm of filament. Then quickly, run the *.bfb (gcode) file. I found printing directly from a cold printer to be problematic...

- Spring tension is also important. In particular for PLA: “PLA needs a lot more pressure then ABS or the feeding will go wrong. When the tensions Is right you will hear a kind of grinding/pulling noise (produced by the filament) that you don’t hear with ABS. It sounds not healthy but it seems to be the only way to keep a solid extrusion going on.” (pieterVL]

- The most important parameters that beginners should know about are highlighted in yellow in the tables.

The Interface

Skeinforge is currently in Beta and each of the three Interfaces I have seen over the last month was different :) - Daniel K. Schneider 11:11, 11 March 2010 (UTC)

Here is a screen-dump of the 2010-03-05 version:

Some parameters for Craft

- Click on the "craft" button to define parameters

- Adjust to the kind of Polymer you are using !! E.g. Colors ABS is different from colorless ABS and hugely different from PLA.

Right now, I somewhat understand color ABS printing, PLA is next on the list, do not trust the PLA values below, it's just copy/past before trying - Daniel K. Schneider 14:19, 11 March 2010 (UTC)

skeinforge allows you to define profiles for different types of polymer. Make sure that make changes for ABS to ABS and to PLA to PLA profile etc. Same when you print !!

Carve

- Defines characteristics of the printer. I left the defaults since they were defined for RapMan.

| Parameter | Explanation | Default | My color ABS | My PLA | Comments |

|---|---|---|---|---|---|

| Layer Thickness (mm) | The thickness of the layer your printer will deposit. This defines: the thickness of layer Skeinforge will cut your object in and therefore the Z step in generated G-Code | 0.4 | 0.4 | 0.4 | I kept this, but for finer lines this might be lowered a tiny bit ? |

| Layers From (index) | If you don't want to print some starting layers | 0 | 0 | 0 | kept this |

| Mesh type | Correctness of the mesh | correct Mesh | - | - | kept this. |

| Perimeter Width over Thickness (ratio) | how thick the perimeter wall will be in relation to the layer thickness. Default value of 1.8 for default thickness of 0.4 states that single filament perimeter wall will be 0.4*1.8=0.72mm thick. This is an important calibration value. You need to be sure that speed of the head and extrusion rate in combination produce walls that are layer thickness * perimeter width over thickness thick | 1.8 | - | 1.5 | I kept this, but certainly should explore this a bit more ... |

Chamber

Turn off, this is to control bed and chamber temperature. (Now what do they mean by "chamber") ? I know that some people have heatable print beds and working in overheated rooms ....

Clip

Clips the ends of loops to prevent bumps from forming

- Default: ON

| Parameter | Explanation | Default | My color ABS | My PLA | Comments | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Clip over Extrusion Width: | Defines the ratio of the amount each end of the loop is clipped over the perimeter width. The total gap will therefore be twice the clip. If the ratio is too high loops will have a gap, if the ratio is too low there will be a bulge at the loop ends. | 0.15 | 0.15 | - | Connect loops | When selected, clip will connect nearby loops, combining them into a spiral. | on | on | ? |

- Default: ON

Comb

Moves the extruder around inside holes to prevent stringers in those holes. Comb bends the extruder travel paths around holes in the slices, to avoid stringers. It moves the extruder to the inside of perimeters before turning the extruder on so any start up ooze will be inside the shape.

- Default: ON

| Parameter | Explanation | Default | My color ABS | My PLA | Comments |

|---|---|---|---|---|---|

| Min Departure Distance over Perimeter Width: | Ratio of the minimum distance that the extruder will travel and loop before leaving a perimeter. A high value means the extruder will loop many times before leaving, so that the ooze will finish within the perimeter, a low value means the extruder will not loop and the stringers will be thicker. Since it sometimes loops when there's no need, the default is zero. | 0 | 0 | 10.0 | |

| Running Jump Space over Perimeter Width | Defines the ratio of the running jump space that is added before going from one island to another to the perimeter width. | 0 | 0 | 2.0 |

Cool

Allows to activate the fan on top with the G-Codes M106 and M107 to turn fan on/off.

Default: ON ??

- For normal ABS turn this OFF

- Probably needed for most other Polymers, e.g. PLA

- If you print little things, e.g. pillars, legs etc. then consider using this feature

Tip:

- If you use cool, then edit the g-code file and remove useless temperature changes. E.g. if you see a repetitive pattern like the following, you can just remove... (at the time of writing, march 11 2010)

M103 M104 S247.0 M104 S245.75

| Parameter | Explanation | Default | My color ABS | My PLA | Comments |

|---|---|---|---|---|---|

| Cool Type | Either use the default orbiting strategy or slow down | Orbit | Orbit | Orbit | |

| Maxium Cool (celsius) | Will automatically cool after printing layers that are defined below. I.e. If it takes less time to extrude the layer than the minimum layer time, then cool will lower the temperature by the 'Maximum Cool' setting times the layer time over the minimum layer time. | 2.0 | 0 ? | 2.0 | This can really slow down printing. After printing a layer, fan turns on, print head goes to the corner, cools down, needs heating up again before going back. I think it should be turned off except for precision printing. |

| Minimum Layer time in seconds | Defines minimum time the extruder will spend on a layer. If printed faster, then the print head will orbit around the printed area for X time that takes to really print the layer before it starts printing the layer. This lets layers with smaller area cool before printing on top of them (so you do not overheat the area). | 60.0 | ? | 1.0 | |

| Minimum Orbital Radius (mmm) | allows you to tweak the minimum orbiting radius so if head does not stay too close the the small areas. | 10.0 | ? | 20.0 | |

| Turn Fan On at Beginning | will turn it on at start | ON | OFF | ON | For ABS I turned this off since it wasn't able to heat up properly ... |

Dimension

Dimension adds Adrian's extruder distance E value to the gcode movement lines.

- Default: OFF

Fill

Allows to define how an object should be filled. This is an important parameter section you should adjust to your needs.

- Default: OFF (put it on for solid objects)

| Parameter | Explanation | Default | My color ABS | My PLA | Comments |

|---|---|---|---|---|---|

| Solid Surface Thickness | Defines the number of solid layers that are at the bottom, top, plateaus and overhang | 3 | 4 (for wide flat objects) | - | |

| Infill Pattern: | Specifies how to fill in empty spaces inside | Grid Hexagonal | - | - | Keep this, it is so pretty |

Fillet

Purpose: Rounding of corners

- Default: OFF

Flow

Can be found under "Speed" since the Feb 2010 version. The flow script sets the flow rate by writing the M108 gcode.

Jitter

Jitter jitters the loop end position to a different place on each layer to prevent the a ridge from forming.

- Default: ON

Multiply

Print several objects.

Raft

Raft is a script to create a raft, elevate the nozzle and set the temperature for the raft. In addition, there are some parameters for the rest of the object in this group (e.g. standard nozzle height). It is very important to get the raft parameters right.

- Base is the first layer and that sticks to the print bed

- Interface are the other raft layers, typically one or two.

- The temperature settings for the raft are in temperature. Also check these !

Tips:

- I like fat rafts and higher temperatures. That makes it stick and I still can get if off easily with a knife.

- When the RapMan is cold, I always move the head to lower right corner (home should be there actually) and extrude about 50cm of filament at high temperatures. (Tool Setup on the bord).

Default: ON

- Activate Raft for ABS !!

- Raft is not needed for PLA, so may turn it off

| Parameter | Explanation | Default | My color ABS | My PLA | Comments |

|---|---|---|---|---|---|

| Base Feed Rate Multiplier | Speed of the print head with respect to default speed | 1 | 1 | - | Slow it down a bit or set a higher flow (below) |

| Base Flow Rate Multiplier | Defines the base flow rate multiplier. The greater the 'Base Flow Rate Multiplier', the thicker the base, the lower the 'Base Flow Rate Multiplier', the thinner the base. | 1.0 | 1.0 | - | |

| Base Infill Density (ratio) | This parameter set the ratio of the base layer fill. Value of 0.1 means that only 10% of the surface will be "covered" and value of 0.9 means that 90% of the surface will be covered. | 0.5 | - | - | I keep that one. |

| Base Layer Thickness over Layer Thickness | This parameter set how much "fatter" the base layer will be compared to normal layer (most important parameter) | 2 | 2.5 | - | I like it fatter |

| Base Nozzle Lift over Base Layer Thickness (ratio) | Modifies the nozzle height for base layer | 0.4 | - | - | Kept this one. If the raft doesn't stick despite large fills and higher temps., you may lower this a tiny bit. |

| Interface Feed Rate Multiplier | As above for the additional raft layers | 1.0 | - | - | |

| Interface Flow Rate Multiplier | As above | 1.0 | - | - | |

| Interface Infill Density (ratio) | Second (and third) layers of the raft. | 0.5 | - | - | I also keep this |

| Operation Nozzle Lift over Layer Thickness (ratio). | Way to modify thickness of the "normal layers" (layers of the object). Range that makes sense is 0.4 to 0.6. | 0.5 | - | - | I kept this one. If you print real fine lines, than you may lower this and the other way round. |

Speed

Speed is a script to set the feed rate (which means head movement speed in mm/s) and flow rate. The resulting thickness of the filament is a combination of the two plus of the temperature.

| Parameter | Explanation | Default | My color ABS | My PLA | Comments |

|---|---|---|---|---|---|

| Add Flow Rate | Will add g-code | On | - | - | If nothing comes out of nozzle check this. |

| Feed Rate | Defines the speed of the print head | 16 millimeters/second | 14 (sometimes) | 16 | seems a bit too much for precision work. |

| Flow Rate | Defines the extrusion rate | 210 | 400 | 380 | This may be too little. I often use 350 or 400 |

| Orbital feedrate over Operating feedrate (ratio) | Speed of the head when "orbiting" related to "normal speed" | 0.5 | 0.5 | 1.0 | PLA seems to need normal speed ... |

| Perimeter Feed Rate over Operating Feed Rate (ratio) | Slows the print head down when printing "outsides. Can give a higher build quality on the outside at the expense of slower build speed | 1 | 0.8 | 1.0 | Most of the time |

| Perimeter Flow Rate over Operating Flow Rate (ratio) | Slows down the flow rate when printer "outsides". In principle, this should match the Perimeter Feed Rate above (else lines will be too fat) | 1 | 0.8 | 1.0 | I use 0.8 most of the time. |

| Travail feed rate | Defines the speed of the print head when it is off | 16 | - | - | slow down for figures with lots of little pieces, since the printer will go bang, bang, bang. |

Temperature

This is mission critical. If you don't get it right:

- Raft will not stick

- Filament will not even come out or burn ....

I think that each parameter should be tuned for high quality printing. For lower quality (and that's what I do right now). I use

- About 238 for raft and support layers with ABS

- About 247 for all other with ABS

| Parameter | Explanation | Default | My color ABS | My PLA | Comments |

|---|---|---|---|---|---|

| Base Temperature | Base temperature, i.e. how it starts printing the first layer of the raft | 200 | 238 | 210 | Default is much too low (ABS in my RapMan likes 238 for the raft...) |

| Interface Temperature | For the second and other layers of the raft. Should be a bit higher than base temp. | 200 | 238 | ??? | I also use 238 since temperature change takes time ... |

| Object First Layer Infill Temperature | Temp. for the fill of the first layer. Should be somewhere in between interface temperature and the following ones (so it won't glue too much) | 200 | 247 | 200 | I use 247 mostly, but should try 243 or something |

| Object First Layer Perimeter Temperature | Outside of first layer. Should be bit higher than the above | 220 | 247 | 200 | I use 247, but should try 245 |

| Object Next Layers Temperature | All other layers | 200 | 247 | 210 | I use 247 or 248, but should try with less sometimes |

| Support Layers Temperature | Usually a bit lower, since adhesion is not need (nobody can see) it and it may be possible to cover greater distances if I understand right | 200 | 247 | 200 | I use 247 or 248, but should try with less sometimes |

A decision table

In the Rapman blog (written on 25 September 2009, retrieved 20:59, 11 March 2010 (UTC)) there is an interesting table that shows the theorectial relationship between Head speed, Extrusion Rate and Layer thickness.

“If you want a layer thickness of 0.35 (first column) at a head speed of 16mm per second (7th column)you would set RPM to 25, the perimeter wall thickness will be 0.63 (13th column) and there will be 2.857143 layers per mm height (14th column)” (David White)

Note: RPMs in skeinforge / g-code are multiplied by 10. E.g. 25RPM is 250.0.

Technical information

Skeinforge is a collection of scripts plus some utilities plus the GUI interface.

Scripts are located here:

- c:/PATH_TO/skeinforge/skeinforge_tools/

When you save a profile, it will put it here:

- c:/users/YOUR_NAME/.skeinforge

E.g.

- extrusion/ABS/termperature

So you also can edit these tab separated files with an editor, if you prefer that.

Links

- Download

- Calibration

- More Skeinforge (BitsFromBytes Blog). Includes an interesting table to use for calibration

- Skeinforge settings (BFB Blog)

- * Skeinforge Quicktip: Fill (outdated with respect to the interface)

- Settings for various filaments

- For ABS, the best information probably is ABS (BitsFromBytes Wiki)

- For PLE, see this forum post and PLA (BFB wiki]

- Skeinforge BFB wiki pages (lots)

- Currently, most are not in synch with the latest version, i.e. parameters are grouped differently and also may have different names ... - 20:09, 11 March 2010 (UTC)

- Skeinforge main page. The follow up the links, e.g.: