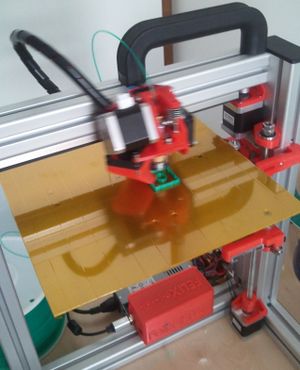

Felix 1.0 3D printer

<pageby comments="false"/>

Introduction

Felix is a low cost 3D Printer, available as kit.

It is the IMHO the most practical printer for schools, since it can be easily carried around and since it has a very stable frame - Daniel K. Schneider 17:01, 18 June 2012 (CEST).

Where and what

Getting it The kit is sold through the felixprinter and costs about 900 € (excluding VAT and shipping costs).

Software

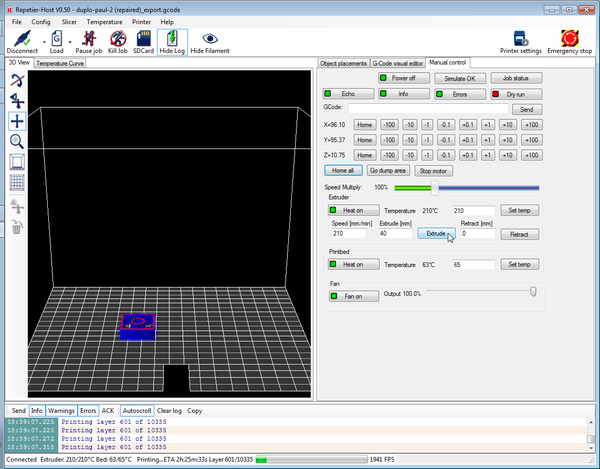

- The open souce Repetier-Host program will pilot the printer through a USB host cable. It will interface with two different [Slicers and user interfaces for 3D printers slicer] programs, i.e. skinforge or Slic3r. A distribution with a pre-configured skeinforge is available from Felix (for registered forum users)

Materials

- 1.75mm PLA rolls

Support

- Felix forums (Registration required for posting and download)

Assembly

Procedure

Assembly of the current model requires some soldering skills as in most other 3D printing kits. Assembling the structure seems to be very easy. Assembly seems to take about 5 to 12 hours depending on your DYI skills. The next version will be easier to assemble according to Guillaume Feliksdal, its creator.

Since we didn't do any assembly, we can't provide any help. The assembly manual seems to be detailed enough.

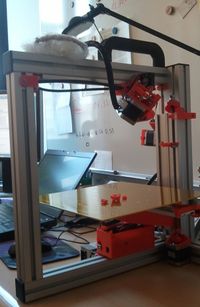

Fully assembled

For now, Felix doesn't offer fully assembled models, but may do so in the future. However, I exceptionally managed to order a fully assembled and tested version. The printer fell off a truck or something and arrived broken. Of course, a fully assembled printer is more fragile, but it was IMHO well packaged in a sturdy box and the Post Office admitted mishandling.

The repaired version arrived via UPS and with different packaging and it worked like a charm out of the box. No calibration was needed, only the software had to installed and configured.

Tips

Heating up

- Heat first both printbed and hotend

- Fan on (100%)

- Before printing, it's a good idea to extrude some 40mm of filament at 200mm/s. If that doesn't work, then reverse extrude a high speed (1000mm/s), cut the filament and reinsert.