Fab lab: Difference between revisions

m (using an external editor) |

m (using an external editor) |

||

| Line 65: | Line 65: | ||

* Additive: Material is successively added into place to build up the desired object. The methods used include selective curing, selective sintering, and aimed deposition. The first commercial additive fabber was introduced in 1987. [This includes the 3D printers that became very cheap and popular in recent years] (DKS). | * Additive: Material is successively added into place to build up the desired object. The methods used include selective curing, selective sintering, and aimed deposition. The first commercial additive fabber was introduced in 1987. [This includes the 3D printers that became very cheap and popular in recent years] (DKS). | ||

* Formative: Material is neither added nor removed, but opposing pressures are applied to the material to modify its shape. Techniques in this category, including automated bending and reconfigurable molding, are under development. | * Formative: Material is neither added nor removed, but opposing pressures are applied to the material to modify its shape. Techniques in this category, including automated bending and reconfigurable molding, are under development. | ||

* Hybrid: Processes from two or more of the above categories are combined. Sheet-based fabbers, which cut and laminate successive layers of sheet material, are hybrid subtractive/additive devices. A combination CNC punch press and press brake is a hybrid subtractive/formative fabber. (retrieved 16: | * Hybrid: Processes from two or more of the above categories are combined. Sheet-based fabbers, which cut and laminate successive layers of sheet material, are hybrid subtractive/additive devices. A combination CNC punch press and press brake is a hybrid subtractive/formative fabber. (retrieved 16:39, 24 June 2009 (UTC)).}} | ||

=== Solid Freeform Fabrication overview === | === Solid Freeform Fabrication overview === | ||

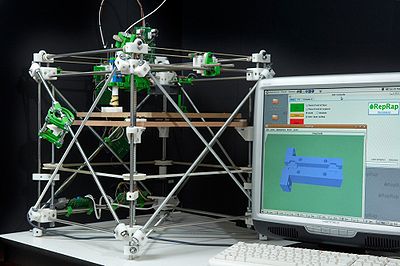

[[image:fab-at-home-fabber.jpg|thumb|400px|right|Fab@Home Fabber model 1, 2007: Source [http://www.fabathome.org/wiki/index.php?title=Image:IMG_0110.jpg fabathome.org]]] | [[image:fab-at-home-fabber.jpg|thumb|400px|right|Fab@Home Fabber model 1, 2007: Source [http://www.fabathome.org/wiki/index.php?title=Image:IMG_0110.jpg fabathome.org]]] | ||

{{quotation|Freeform Fabrication is a collection of manufacturing technologies with which parts can be created without the need for part-specific tooling. A computerized model of the part is designed. It is sliced computationally, and layer information is sent to a fabricator that reproduces the layer in a real material}} ([http://utwired.engr.utexas.edu/lff/ Laboratory of Freeform Fabrication], UTexas, retrieved 16: | {{quotation|Freeform Fabrication is a collection of manufacturing technologies with which parts can be created without the need for part-specific tooling. A computerized model of the part is designed. It is sliced computationally, and layer information is sent to a fabricator that reproduces the layer in a real material}} ([http://utwired.engr.utexas.edu/lff/ Laboratory of Freeform Fabrication], UTexas, retrieved 16:39, 24 June 2009 (UTC)). Commercial "low-cost" free form fabricators range between 20'000 and 300'000 $US. Open source kits are much cheaper (see below) | ||

Currently, low-end commercial 3D prototypers are still costly for individuals who want to "play" or schools. On June 2009, the cheapest 3D printer we found cost $5000 from Desktop Factory, the next one was "Dimension uPrint" and cost £12000. In addition you need to buy materials and solidifiers. | Currently, low-end commercial 3D prototypers are still costly for individuals who want to "play" or schools. On June 2009, the cheapest 3D printer we found cost $5000 from Desktop Factory, the next one was "Dimension uPrint" and cost £12000. In addition you need to buy materials and solidifiers. | ||

According to [ Wikipedia] (retrieved 16: | According to [ Wikipedia] (retrieved 16:39, 24 June 2009 (UTC)), {{quotation|Prototypes made by these low-end commercial machines cost around US$2 per cubic centimeter to fabricate. The RepRap Project is on track to produce a 3D prototyping machine and free and open source accompanying software that costs about US$400 to build and which can fabricate objects at a cost of about US$0.02 per cubic centimeter.}} | ||

Low End Solid Freeform Fabrication tools, also called '''rapid prototype machines''' are usually a kind of '''3D printers'''. {{quotation|3D printing is a unique form of fabrication that is related to traditional rapid prototyping technology. A three dimensional object is created by layering and connecting successive cross sections of material. 3D printers are generally faster, more affordable and easier to use than other additive fabrication technologies. While prototyping dominates current uses, 3D printers offers tremendous potential for retail consumer uses.}} ([http://en.wikipedia.org/wiki/3D_printing Wikipedia], retrieved 16: | Low End Solid Freeform Fabrication tools, also called '''rapid prototype machines''' are usually a kind of '''3D printers'''. {{quotation|3D printing is a unique form of fabrication that is related to traditional rapid prototyping technology. A three dimensional object is created by layering and connecting successive cross sections of material. 3D printers are generally faster, more affordable and easier to use than other additive fabrication technologies. While prototyping dominates current uses, 3D printers offers tremendous potential for retail consumer uses.}} ([http://en.wikipedia.org/wiki/3D_printing Wikipedia], retrieved 16:39, 24 June 2009 (UTC)). | ||

There exist various kinds of 3D printers, e.g. Inkjet where layers of powder (e.g. plaster, corn starch or resins) are selectively bonded or photopolymer machines that fix liquids with an UV flood lamp. A low-cost fabber, typically includes a kind of "gun" that heats up polymer plastic from a filament and then extrudes a fine stream to build things. | There exist various kinds of 3D printers, e.g. Inkjet where layers of powder (e.g. plaster, corn starch or resins) are selectively bonded or photopolymer machines that fix liquids with an UV flood lamp. A low-cost fabber, typically includes a kind of "gun" that heats up polymer plastic from a filament and then extrudes a fine stream to build things. | ||

| Line 84: | Line 84: | ||

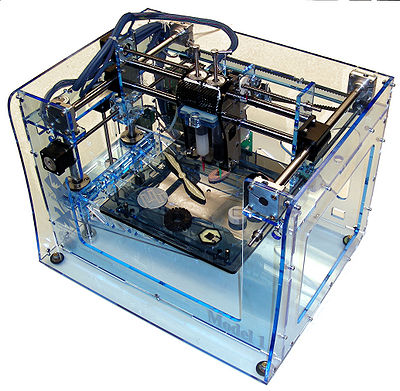

[[image:reprap.jpg|thumb|400px|right|RepRap self-replicating 3D printer]] | [[image:reprap.jpg|thumb|400px|right|RepRap self-replicating 3D printer]] | ||

[http://reprap.org/ RepRap] is another well know project. {{quotation|RepRap is short for Replicating Rapid-prototyper. It is the practical self-copying 3D printer shown on the right - a self-replicating machine. This 3D printer builds the parts up in layers of plastic. This technology already exists, but the cheapest commercial machine would cost you about €30,000. And it isn't even designed so that it can make itself. So what the RepRap team are doing is to develop and to give away the designs for a much cheaper machine with the novel capability of being able to self-copy (material costs are about €500). That way it's accessible to small communities in the developing world as well as individuals in the developed world. Following the principles of the Free Software Movement we are distributing the RepRap machine at no cost to everyone under the GNU General Public Licence. So, if you have a RepRap machine, you can use it to make another and give that one to a friend...}} ([http://reprap.org/bin/view/Main/WebHome What is RepRap?], retrieved 16: | [http://reprap.org/ RepRap] is another well know project. {{quotation|RepRap is short for Replicating Rapid-prototyper. It is the practical self-copying 3D printer shown on the right - a self-replicating machine. This 3D printer builds the parts up in layers of plastic. This technology already exists, but the cheapest commercial machine would cost you about €30,000. And it isn't even designed so that it can make itself. So what the RepRap team are doing is to develop and to give away the designs for a much cheaper machine with the novel capability of being able to self-copy (material costs are about €500). That way it's accessible to small communities in the developing world as well as individuals in the developed world. Following the principles of the Free Software Movement we are distributing the RepRap machine at no cost to everyone under the GNU General Public Licence. So, if you have a RepRap machine, you can use it to make another and give that one to a friend...}} ([http://reprap.org/bin/view/Main/WebHome What is RepRap?], retrieved 16:39, 24 June 2009 (UTC)). | ||

Until recently, fabbers had to be assembled by the end-user using open designs and low-level parts, i.e. many many days of bricolage. However, some fabbers now can be bought commercially as easy kits or fully assembled. E.g. in ''June 2009'', the [http://store02.prostores.com/servlet/kobask8/StoreFront NextFab Store] sold kits for about $3000 and assembled Fab@Homes for about $4000. [http://www.bitsfrombytes.com/ Bits from Byte] sold a [http://www.bitsfrombytes.com/index.php?option=com_content&view=article&id=77&Itemid=100006 ReRap kit] (Version 3 - RapMan) for about £750. | Until recently, fabbers had to be assembled by the end-user using open designs and low-level parts, i.e. many many days of bricolage. However, some fabbers now can be bought commercially as easy kits or fully assembled. E.g. in ''June 2009'', the [http://store02.prostores.com/servlet/kobask8/StoreFront NextFab Store] sold kits for about $3000 and assembled Fab@Homes for about $4000. [http://www.bitsfrombytes.com/ Bits from Byte] sold a [http://www.bitsfrombytes.com/index.php?option=com_content&view=article&id=77&Itemid=100006 ReRap kit] (Version 3 - RapMan) for about £750. | ||

| Line 91: | Line 91: | ||

; Laser cutters and engravers | ; Laser cutters and engravers | ||

: Laser cutters and engravers can process any non-metal material (e.g. acrylic, ceramics, cork, fiberglass, glass, plastic, leather, paper, stone, wood). {{quotation|Laser cutting is a technology that uses a laser to cut materials, which is used in the production line and is typically used for industrial manufacturing applications. Laser cutting works by directing the output of a high power laser, by computer, at the material to be cut. The material then either melts, burns, vaporizes away, or is blown away by a jet of gas, [1] leaving an edge with a high quality surface finish. Industrial laser cutters are used to cut flat-sheet material as well as structural and piping materials.}} ([http://en.wikipedia.org/wiki/Laser_cutting Wikipedia], retrieved 16: | : Laser cutters and engravers can process any non-metal material (e.g. acrylic, ceramics, cork, fiberglass, glass, plastic, leather, paper, stone, wood). {{quotation|Laser cutting is a technology that uses a laser to cut materials, which is used in the production line and is typically used for industrial manufacturing applications. Laser cutting works by directing the output of a high power laser, by computer, at the material to be cut. The material then either melts, burns, vaporizes away, or is blown away by a jet of gas, [1] leaving an edge with a high quality surface finish. Industrial laser cutters are used to cut flat-sheet material as well as structural and piping materials.}} ([http://en.wikipedia.org/wiki/Laser_cutting Wikipedia], retrieved 16:39, 24 June 2009 (UTC)). | ||

; Plasma cutters | ; Plasma cutters | ||

: {{quotation|Plasma cutting is a process that is used to cut steel and other metals of different thicknesses (or sometimes other materials) using a plasma torch. In this process, an inert gas (in some units, compressed air) is blown at high speed out of a nozzle; at the same time an electrical arc is formed through that gas from the nozzle to the surface being cut, turning some of that gas to plasma. The plasma is sufficiently hot to melt the metal being cut and moves sufficiently fast to blow molten metal away from the cut. Plasma can also be used for plasma arc welding and other applications.}} ([http://en.wikipedia.org/wiki/Plasma_cutting Wikipedia], retrieved 16: | : {{quotation|Plasma cutting is a process that is used to cut steel and other metals of different thicknesses (or sometimes other materials) using a plasma torch. In this process, an inert gas (in some units, compressed air) is blown at high speed out of a nozzle; at the same time an electrical arc is formed through that gas from the nozzle to the surface being cut, turning some of that gas to plasma. The plasma is sufficiently hot to melt the metal being cut and moves sufficiently fast to blow molten metal away from the cut. Plasma can also be used for plasma arc welding and other applications.}} ([http://en.wikipedia.org/wiki/Plasma_cutting Wikipedia], retrieved 16:39, 24 June 2009 (UTC)). | ||

Plasma cutters come in various sizes are available from $3000. | Plasma cutters come in various sizes are available from $3000. | ||

| Line 106: | Line 106: | ||

=== Selective Laser sintering === | === Selective Laser sintering === | ||

{{quotation|In the Selective Laser Sintering (SLS) process, three-dimensional parts are created by fusing (or sintering) powdered thermoplastic materials with the heat from an infrared laser beam.}} ([http://www.protocam.com/html/sls.html Selective Laser Sintering (SLS), SLS Prototype], retrieved 16: | {{quotation|In the Selective Laser Sintering (SLS) process, three-dimensional parts are created by fusing (or sintering) powdered thermoplastic materials with the heat from an infrared laser beam.}} ([http://www.protocam.com/html/sls.html Selective Laser Sintering (SLS), SLS Prototype], retrieved 16:39, 24 June 2009 (UTC)). | ||

:{{quotation|Selective laser sintering is an additive rapid manufacturing technique that uses a high power LASER (for example, a carbon dioxide laser) to fuse small particles of plastic, metal, ceramic, or glass powders into a mass representing a desired 3-dimensional object. The laser selectively fuses powdered material by scanning cross-sections generated from a 3-D digital description of the part}} ([http://en.wikipedia.org/wiki/Selective_laser_sintering Wikipedia], retrieved 16: | :{{quotation|Selective laser sintering is an additive rapid manufacturing technique that uses a high power LASER (for example, a carbon dioxide laser) to fuse small particles of plastic, metal, ceramic, or glass powders into a mass representing a desired 3-dimensional object. The laser selectively fuses powdered material by scanning cross-sections generated from a 3-D digital description of the part}} ([http://en.wikipedia.org/wiki/Selective_laser_sintering Wikipedia], retrieved 16:39, 24 June 2009 (UTC)). | ||

This technology looks rather complex and expensive, compared to low-end 3D printers... | This technology looks rather complex and expensive, compared to low-end 3D printers... | ||

| Line 114: | Line 114: | ||

=== Stereolithography === | === Stereolithography === | ||

{{quotation|Stereolithography is a common rapid manufacturing and rapid prototyping technology for producing parts with high accuracy and good surface finish. A device that performs stereolithography is called an SLA or Stereolithography Apparatus.}} ([http://en.wikipedia.org/wiki/Stereolithography Wikipedia], retrieved 16: | {{quotation|Stereolithography is a common rapid manufacturing and rapid prototyping technology for producing parts with high accuracy and good surface finish. A device that performs stereolithography is called an SLA or Stereolithography Apparatus.}} ([http://en.wikipedia.org/wiki/Stereolithography Wikipedia], retrieved 16:39, 24 June 2009 (UTC)). | ||

SLA is too expensive for fab labs (between $100,000 and $400,000) | SLA is too expensive for fab labs (between $100,000 and $400,000) | ||

| Line 132: | Line 132: | ||

[http://www.arduino.cc/ Arduino] {{quotation|is an open-source electronics prototyping platform based on flexible, easy-to-use hardware and software. It's intended for artists, designers, hobbyists, and anyone interested in creating interactive objects or environments.<br/> | [http://www.arduino.cc/ Arduino] {{quotation|is an open-source electronics prototyping platform based on flexible, easy-to-use hardware and software. It's intended for artists, designers, hobbyists, and anyone interested in creating interactive objects or environments.<br/> | ||

Arduino can sense the environment by receiving input from a variety of sensors and can affect its surroundings by controlling lights, motors, and other actuators. The microcontroller on the board is programmed using the Arduino programming language (based on Wiring) and the Arduino development environment (based on Processing). Arduino projects can be stand-alone or they can communicate with software on running on a computer (e.g. Flash, Processing, MaxMSP).}} ([http://www.arduino.cc/ Arduino Home Page], retrieved 16: | Arduino can sense the environment by receiving input from a variety of sensors and can affect its surroundings by controlling lights, motors, and other actuators. The microcontroller on the board is programmed using the Arduino programming language (based on Wiring) and the Arduino development environment (based on Processing). Arduino projects can be stand-alone or they can communicate with software on running on a computer (e.g. Flash, Processing, MaxMSP).}} ([http://www.arduino.cc/ Arduino Home Page], retrieved 16:39, 24 June 2009 (UTC)). | ||

| Line 140: | Line 140: | ||

; .STL | ; .STL | ||

: {{quotation|An StL (“StereoLithography”) file is a triangular representation of a 3-dimensional surface geometry. The surface is tessellated or broken down logically into a series of small triangles (facets). Each facet is described by a perpendicular direction and three points representing the vertices (corners) of the triangle. These data are used by a slicing algorithm to determine the cross sections of the 3-dimensional shape to be built by the fabber}} ([http://www.ennex.com/~fabbers/StL.asp The StL Format], retrieved 16: | : {{quotation|An StL (“StereoLithography”) file is a triangular representation of a 3-dimensional surface geometry. The surface is tessellated or broken down logically into a series of small triangles (facets). Each facet is described by a perpendicular direction and three points representing the vertices (corners) of the triangle. These data are used by a slicing algorithm to determine the cross sections of the 3-dimensional shape to be built by the fabber}} ([http://www.ennex.com/~fabbers/StL.asp The StL Format], retrieved 16:39, 24 June 2009 (UTC)). | ||

; .PLY | ; .PLY | ||

| Line 163: | Line 163: | ||

* [http://fab.cba.mit.edu/ FabCentral], The Center for Bits and Atoms, MIT. | * [http://fab.cba.mit.edu/ FabCentral], The Center for Bits and Atoms, MIT. | ||

** [http://fab.cba.mit.edu/about/faq/ Fab Lab FAQ], MIT. (includes further pointers). | |||

** [http://fab.cba.mit.edu/classes/MIT/863.08/people/alex_schaub/ How to make (almost) anything] (alex schaub's mas863 log Fall 2008). Illustrates what could be done. | |||

* [http://en.wikipedia.org/wiki/3D_printing Wikipedia] | * [http://en.wikipedia.org/wiki/3D_printing Wikipedia] | ||

* [http://en.wikipedia.org/wiki/Category:Solid_freeform_fabrication Category:Solid freeform fabrication] (Wikipedia). | * [http://en.wikipedia.org/wiki/Category:Solid_freeform_fabrication Category:Solid freeform fabrication] (Wikipedia). | ||

| Line 174: | Line 177: | ||

* [http://en.wikipedia.org/wiki/Solid_freeform_fabrication Solid freeform fabrication] (Wikipedia, overview). | * [http://en.wikipedia.org/wiki/Solid_freeform_fabrication Solid freeform fabrication] (Wikipedia, overview). | ||

* [http://home.att.net/~castleisland/rp_int1.htm The Most Important Commercial | * [http://home.att.net/~castleisland/rp_int1.htm The Most Important Commercial Rapid Prototyping Technologies at a Glance] | ||

Rapid Prototyping Technologies at a Glance] | |||

* [http://seedmagazine.com/content/article/is_mit_obsolete/ On the future of invention], by Neil Gershenfeld, Seedmagazine, June 24, 2009. | * [http://seedmagazine.com/content/article/is_mit_obsolete/ On the future of invention], by Neil Gershenfeld, Seedmagazine, June 24, 2009. | ||

| Line 181: | Line 183: | ||

* [http://www.economist.com/science/displayStory.cfm?story_id=3786368 Desktop manufacturing - Helping poor-world inventors], The Economist, Mar 23 2005. | * [http://www.economist.com/science/displayStory.cfm?story_id=3786368 Desktop manufacturing - Helping poor-world inventors], The Economist, Mar 23 2005. | ||

* [http://www.ennex.com/~fabbers/intro.asp What is a Fabber?, An Introduction to the 21st Century], Ennex Corporation, retrieved 16: | * [http://www.ennex.com/~fabbers/intro.asp What is a Fabber?, An Introduction to the 21st Century], Ennex Corporation, retrieved 16:39, 24 June 2009 (UTC). | ||

* [http://www.popularmechanics.com/automotive/jay_leno_garage/4320759.html Jay Leno’s 3D Printer Replaces Rusty Old Parts] | * [http://www.popularmechanics.com/automotive/jay_leno_garage/4320759.html Jay Leno’s 3D Printer Replaces Rusty Old Parts] | ||

* [http://www.rapidprototypinghomepage.com/ Rapid Prototyping Home Page] | * [http://www.rapidprototypinghomepage.com/ Rapid Prototyping Home Page] | ||

=== Numerical control === | === Numerical control === | ||

| Line 204: | Line 202: | ||

* [http://www.rap-man.com/ A1 Technologies]. Sells Rapman systems (£750). | * [http://www.rap-man.com/ A1 Technologies]. Sells Rapman systems (£750). | ||

* [http://en.wikipedia.org/wiki/RepRap_Project RepRap Project] (Wikipedia) | * [http://en.wikipedia.org/wiki/RepRap_Project RepRap Project] (Wikipedia) | ||

* [http://reprap.org/bin/view/Main/ShowCase Introduction to Reprap], retrieved 16: | * [http://reprap.org/bin/view/Main/ShowCase Introduction to Reprap], retrieved 16:39, 24 June 2009 (UTC). | ||

* [http://reprap.blogspot.com/ RepRap Official Blog] | * [http://reprap.blogspot.com/ RepRap Official Blog] | ||

| Line 244: | Line 242: | ||

=== Stereolithography (SLA) === | === Stereolithography (SLA) === | ||

* [http://home.att.net/~castleisland/sl.htm Stereolithography (SLA)], Castle Island Co., retrieved 16: | * [http://home.att.net/~castleisland/sl.htm Stereolithography (SLA)], Castle Island Co., retrieved 16:39, 24 June 2009 (UTC) | ||

=== Arduino === | === Arduino === | ||

Revision as of 17:39, 24 June 2009

This article or section is currently under construction

In principle, someone is working on it and there should be a better version in a not so distant future.

If you want to modify this page, please discuss it with the person working on it (see the "history")

Introduction

A Fab Lab (fabrication laboratory) is a small-scale workshop with computer controlled tools with the aim to make "almost anything". (Wikipedia). Fab labs are a disruptive technology.

Fab labs can have different aims, e.g. rapid prototyping or low cost and on-demand manufacturing from "open source designs" for both hobbyist and serious use. Both purposes include an idea of empowering individuals to create devices that are adapted to specific needs.

The Fab@Home project emphasizes freedom of design and innovation of a Solid Freeform Fabrication system:

In a similar way IFTF, in the Future of Making Map argues:

Finally, the topic of the LIFT France 0.9 conference was Hands-on future. According to Laurent Haug,

What happened in the software industry - young guys waking up with an idea, ending up changing the world from their sofa like it happened with Google, Amazon, Facebook, etc. - is now happening in the tangible world. Things like Arduino are enabling hackers and creators all around the globe, and what was possible with software (easily assemble code to create new applications) is now possible with objects. The conference program was centered around three main topics:

- Changing Things: Towards objects that are not just “smart” and connected, but also customizable, hackable, transformable, fully recyclable… Towards decentralized and multipurpose manufacturing, or even home fabrication…

- Changing Innovation: Towards continuous and networked innovation, emerging from users as well as entrepreneurs, from researchers as well as activists…

- Changing the Planet: Towards a “green design” that reconnects global environmental challenges with growth, but also with human desire, pleasure, beauty and fun ...

The first Fab Lab emerged at MIT under the direction of N. Gershenfeld. It included a laser cutter, a miniature milling machine and jigsaw cutting machine.

The Fab Lab movement also is anchored in ecological thinking. “Think of RepRap as a China on your desktop” (Chris di Bona). Materials used are no much polluting and there is no transportation cost.

History

- 1940's

- Birth of numerical control, i.e. machine tools controlled by code.

- mid 1950's

- Birth of special purpose programming languages for computer numerical controlled (CNC) machine tools.

- end 1950's - mid 1960's

- Birth of interfaces of Computer-aided design (CAD) with CNC.

- 1970

- Mohamed Hashish created a technique to add abrasives to the water jet cutter

- 1986

- 3D-Printing

- 2005

- Neil Gershenfeld's et al. MIT class 863.04 - how to make (almost) anything.

- 2006

- The RepRap prototype

- 2007

- Neil Gershenfeld and Joe Jacobson MIT class How To Make Something That Makes (almost) Anything.

Technology - Tools

There exist several popular fab lab technologies, some of which are described below in more details. Most fall in the category of solid freeform fabrication tools and that include:

- 3D printers

- Laser cutters

- CNC machines

- Automated paper cutters

- 3D Scanners (for replication)

- Laser sintering

Another set of toolkits are electronics platforms like Arduino.

A fabber (or digital fabricator) refers to a "factory in box" (i.e. one of the above tools) that can create things automatically from digital data. The Digital Fabrication Portal distinguishes three fundamental kinds of fabbers, according to the way they operate on their raw material:

- Subtractive: Material is carved away from a solid block, such as by milling, turning, or electrodischarge machining (EDM). Subtractive fabbers have been automated since the late 1940s, and are often called computer-numerically controlled (CNC) machines.

- Additive: Material is successively added into place to build up the desired object. The methods used include selective curing, selective sintering, and aimed deposition. The first commercial additive fabber was introduced in 1987. [This includes the 3D printers that became very cheap and popular in recent years] (DKS).

- Formative: Material is neither added nor removed, but opposing pressures are applied to the material to modify its shape. Techniques in this category, including automated bending and reconfigurable molding, are under development.

- Hybrid: Processes from two or more of the above categories are combined. Sheet-based fabbers, which cut and laminate successive layers of sheet material, are hybrid subtractive/additive devices. A combination CNC punch press and press brake is a hybrid subtractive/formative fabber. (retrieved 16:39, 24 June 2009 (UTC)).

Solid Freeform Fabrication overview

“Freeform Fabrication is a collection of manufacturing technologies with which parts can be created without the need for part-specific tooling. A computerized model of the part is designed. It is sliced computationally, and layer information is sent to a fabricator that reproduces the layer in a real material” (Laboratory of Freeform Fabrication, UTexas, retrieved 16:39, 24 June 2009 (UTC)). Commercial "low-cost" free form fabricators range between 20'000 and 300'000 $US. Open source kits are much cheaper (see below)

Currently, low-end commercial 3D prototypers are still costly for individuals who want to "play" or schools. On June 2009, the cheapest 3D printer we found cost $5000 from Desktop Factory, the next one was "Dimension uPrint" and cost £12000. In addition you need to buy materials and solidifiers. According to [ Wikipedia] (retrieved 16:39, 24 June 2009 (UTC)), “Prototypes made by these low-end commercial machines cost around US$2 per cubic centimeter to fabricate. The RepRap Project is on track to produce a 3D prototyping machine and free and open source accompanying software that costs about US$400 to build and which can fabricate objects at a cost of about US$0.02 per cubic centimeter.”

Low End Solid Freeform Fabrication tools, also called rapid prototype machines are usually a kind of 3D printers. “3D printing is a unique form of fabrication that is related to traditional rapid prototyping technology. A three dimensional object is created by layering and connecting successive cross sections of material. 3D printers are generally faster, more affordable and easier to use than other additive fabrication technologies. While prototyping dominates current uses, 3D printers offers tremendous potential for retail consumer uses.” (Wikipedia, retrieved 16:39, 24 June 2009 (UTC)).

There exist various kinds of 3D printers, e.g. Inkjet where layers of powder (e.g. plaster, corn starch or resins) are selectively bonded or photopolymer machines that fix liquids with an UV flood lamp. A low-cost fabber, typically includes a kind of "gun" that heats up polymer plastic from a filament and then extrudes a fine stream to build things.

Low cost fabbers

Very low-cost non-proprietary 3D printers are often referred to as Fabbers. The Fab@Home project (retrieved June 2009) “is a project dedicated to making and using fabbers - machines that can make almost anything, right on your desktop. [...] Fabbers (a.k.a. 3D printers or rapid prototyping machines) are a relatively new form of manufacturing that builds 3D objects by carefully depositing materials drop by drop, layer by layer. With the right set of materials and a geometric blueprint, you can fabricate complex objects that would normally take special resources, tools and skills if produced using conventional manufacturing techniques. A fabber can allow you to explore new designs, email physical objects to other fabber owners, and most importantly - set your ideas free. Just as MP3s, iPods and the Internet have freed musical talent, we hope that blueprints and fabbers will democratize innovation.”

RepRap is another well know project. “RepRap is short for Replicating Rapid-prototyper. It is the practical self-copying 3D printer shown on the right - a self-replicating machine. This 3D printer builds the parts up in layers of plastic. This technology already exists, but the cheapest commercial machine would cost you about €30,000. And it isn't even designed so that it can make itself. So what the RepRap team are doing is to develop and to give away the designs for a much cheaper machine with the novel capability of being able to self-copy (material costs are about €500). That way it's accessible to small communities in the developing world as well as individuals in the developed world. Following the principles of the Free Software Movement we are distributing the RepRap machine at no cost to everyone under the GNU General Public Licence. So, if you have a RepRap machine, you can use it to make another and give that one to a friend...” (What is RepRap?, retrieved 16:39, 24 June 2009 (UTC)).

Until recently, fabbers had to be assembled by the end-user using open designs and low-level parts, i.e. many many days of bricolage. However, some fabbers now can be bought commercially as easy kits or fully assembled. E.g. in June 2009, the NextFab Store sold kits for about $3000 and assembled Fab@Homes for about $4000. Bits from Byte sold a ReRap kit (Version 3 - RapMan) for about £750.

Cutters

- Laser cutters and engravers

- Laser cutters and engravers can process any non-metal material (e.g. acrylic, ceramics, cork, fiberglass, glass, plastic, leather, paper, stone, wood). “Laser cutting is a technology that uses a laser to cut materials, which is used in the production line and is typically used for industrial manufacturing applications. Laser cutting works by directing the output of a high power laser, by computer, at the material to be cut. The material then either melts, burns, vaporizes away, or is blown away by a jet of gas, [1] leaving an edge with a high quality surface finish. Industrial laser cutters are used to cut flat-sheet material as well as structural and piping materials.” (Wikipedia, retrieved 16:39, 24 June 2009 (UTC)).

- Plasma cutters

- “Plasma cutting is a process that is used to cut steel and other metals of different thicknesses (or sometimes other materials) using a plasma torch. In this process, an inert gas (in some units, compressed air) is blown at high speed out of a nozzle; at the same time an electrical arc is formed through that gas from the nozzle to the surface being cut, turning some of that gas to plasma. The plasma is sufficiently hot to melt the metal being cut and moves sufficiently fast to blow molten metal away from the cut. Plasma can also be used for plasma arc welding and other applications.” (Wikipedia, retrieved 16:39, 24 June 2009 (UTC)).

Plasma cutters come in various sizes are available from $3000.

- Water jet cutter

- “A water jet cutter is a tool capable of slicing into metal or other materials using a jet of water at high velocity and pressure, or a mixture of water and an abrasive substance. The process is essentially the same as water erosion found in nature but greatly accelerated and concentrated. It is often used during fabrication or manufacture of parts for machinery and other devices” (Wikipedia, retrieved 21:22, 23 June 2009 (UTC).)

According to Wikipedia, water jets can cut with a with of about 1mm and can cut materials such as rubber, foam, plastics, composites, stone, glass, tile, metals, food, paper and much more. Also, water jets can cut material without much harming or changing the materials' structures since there is no heat. I also can be considered a green technology, since it doesn't produce harmful waste. Water and abrasives can be recycled.

Selective Laser sintering

“In the Selective Laser Sintering (SLS) process, three-dimensional parts are created by fusing (or sintering) powdered thermoplastic materials with the heat from an infrared laser beam.” (Selective Laser Sintering (SLS), SLS Prototype, retrieved 16:39, 24 June 2009 (UTC)).

- “Selective laser sintering is an additive rapid manufacturing technique that uses a high power LASER (for example, a carbon dioxide laser) to fuse small particles of plastic, metal, ceramic, or glass powders into a mass representing a desired 3-dimensional object. The laser selectively fuses powdered material by scanning cross-sections generated from a 3-D digital description of the part” (Wikipedia, retrieved 16:39, 24 June 2009 (UTC)).

This technology looks rather complex and expensive, compared to low-end 3D printers...

Stereolithography

“Stereolithography is a common rapid manufacturing and rapid prototyping technology for producing parts with high accuracy and good surface finish. A device that performs stereolithography is called an SLA or Stereolithography Apparatus.” (Wikipedia, retrieved 16:39, 24 June 2009 (UTC)).

SLA is too expensive for fab labs (between $100,000 and $400,000)

CNC mills

A milling machine (fr. "fraiseuse") is a machine tool used for the shaping of metal and other solid materials. It uses rotating cutters to cut stuff from a workpiece. In more sophisticated milling machines, both the cutters and the workpiece can be rotated in three axis.

3D Scanners

An alternative to designing objects is to scan them. 3D scanners can be bought for about $3000.

Electronic kits

- Arduino

Arduino “is an open-source electronics prototyping platform based on flexible, easy-to-use hardware and software. It's intended for artists, designers, hobbyists, and anyone interested in creating interactive objects or environments.

Arduino can sense the environment by receiving input from a variety of sensors and can affect its surroundings by controlling lights, motors, and other actuators. The microcontroller on the board is programmed using the Arduino programming language (based on Wiring) and the Arduino development environment (based on Processing). Arduino projects can be stand-alone or they can communicate with software on running on a computer (e.g. Flash, Processing, MaxMSP).” (Arduino Home Page, retrieved 16:39, 24 June 2009 (UTC)).

File formats

See also Computer-aider design (CAD)

- .STL

- “An StL (“StereoLithography”) file is a triangular representation of a 3-dimensional surface geometry. The surface is tessellated or broken down logically into a series of small triangles (facets). Each facet is described by a perpendicular direction and three points representing the vertices (corners) of the triangle. These data are used by a slicing algorithm to determine the cross sections of the 3-dimensional shape to be built by the fabber” (The StL Format, retrieved 16:39, 24 June 2009 (UTC)).

- .PLY

- OBJ

- VRML

- XYZ

- STEP

- IGES

Software

- ReplicatorG is the software that will drive your CupCake CNC, RepRap machine, or generic CNC machine. You feed it GCode, it parses the GCode, and then controls your machine via a driver. Its cross platform, easily installed, and is based on the familiar Arduino / Processing environments.

Links

Fab Labs, fabbers and rapid prototyping

- FabCentral, The Center for Bits and Atoms, MIT.

- Fab Lab FAQ, MIT. (includes further pointers).

- How to make (almost) anything (alex schaub's mas863 log Fall 2008). Illustrates what could be done.

- Wikipedia

- Category:Solid freeform fabrication (Wikipedia).

- Desktop manufacturing (Wikipedia)

- Digital fabricator (Wikipedia)

- Fabber (Wikipedia).

- Solid freeform fabrication (Wikipedia, overview).

- On the future of invention, by Neil Gershenfeld, Seedmagazine, June 24, 2009.

- Desktop manufacturing - Helping poor-world inventors, The Economist, Mar 23 2005.

- What is a Fabber?, An Introduction to the 21st Century, Ennex Corporation, retrieved 16:39, 24 June 2009 (UTC).

Numerical control

- Numerical control (Wikipedia)

Cheap open source 3D printers

- Fab@Home 3D printer

- Fab@Home, is a project dedicated to making and using fabbers - machines that can make almost anything, right on your desktop. This website provides everything you need to know in order to build or buy your own simple fabber, and to use it to print three dimensional object. Hardware designs and software on this website are open source.

- Reprap 3D printer

- Bits from Bytes. Sells RepRap kits (£750).

- A1 Technologies. Sells Rapman systems (£750).

- RepRap Project (Wikipedia)

- Introduction to Reprap, retrieved 16:39, 24 June 2009 (UTC).

- RepRap Official Blog

- Cupcake

- Cupcake is a 3D printer that works with four kinds of plastic, e.g. ABS (Lego-like) and HDPE (milk-jug like).

- MakerBot Industries sells CupCake (a 3D prototyper). It includes a Plastruder and an Arduino compatible microcontroller.

- CupCake CNC Basic Kit Product page ($750).

- CupCake CNC overview.

- Other links

- Three dimensional printing Laboratory (MIT,last update 2000)

Commercial entry-level 3D printers

- 3D Printer System Manufacturers - Systems for Less Than US$20,000 (parts for self-assembly can be as low as $600)

- Desktop Factory 125ci 3D Printer (about $5000). See also the Wikipedia entry.

- uPrint from Dimension (about £12'000).

- Alaris from Object (price ???)

- V-Flash from 3D Systems. (price about $10'000 ?)

Laser and plasma cutters

- How Plasma Cutters Work (Howstuffworks.com).

Water jets

CNC mills

Selective Laster Sintering (SLS)

Stereolithography (SLA)

- Stereolithography (SLA), Castle Island Co., retrieved 16:39, 24 June 2009 (UTC)

Arduino

- Arduino (Home page)

- YouTube Videos

New technology mags, blogs and communities

- SEED magazine

- NewScientist (tech section)

- FabLabs - a space for those tinkering with Fab Labs

- Thingiverse. Is a place for you to share your digital designs with the world.

- Hacked Gadgets

- NYC Resistor is a hacker collective with a shared space located in downtown Brooklyn.

- Next Big Future (blog)

- Pasta&Vinegar, Nicolas Nova, LiftLab (mind/tech bazar from outer space blog).

- The LIFT conference series (organized by our friends from LiftLab).

- Make magazine

Fab Labs

- Fab Academy (MIT) A news project in June 2009.

- Fablab Amsterdam

- Laboratory for Freeform Fabrication (UTexas).

Bibliography

- Burns M., (1995) The Freedom to Create, in Technology Management, Volume 1, Number 4 http://www.ennex.com/~fabbers/publish/199407-MB-FreedomCreate.asp

- Gershenfeld, Neil, A., (2005) FAB: The Coming Revolution on Your Desktop – From Personal Computers to Personal Fabrication, Basic Books, ISBN 0-465-02745-8.

- Editors' Review (2005). Desktop Factories - FAB The Coming Revolution on Your Desktop -- from Personal Computers to Personal Fabrication By Neil Gershenfeld, Basic Books, Business Week, May 2 2005.

- Gershenfeld N. Think Globally, fabricate locally, PrincipalVoices.com. PDF (reprint)

- Institute of the Future (2009). The future of making, PDF

- Jenweill, Mark, Fab Labs unshackle imaginations, USA Today, 11/6/2005.

- Lipson H. (2005) "Homemade: The future of Functional Rapid Prototyping", IEEE Spectrum, feature article, May 2005, pp. 24-31 http://www.mae.cornell.edu/ccsl/papers/Spectrum05_Lipson.pdf

- Bowyer A., RepRap: The Replicating Rapid-Prototyper, http://reprap.org

- Thomson, Clive (2008). Build It. Share It. Profit. Can Open Source Hardware Work? Wired Magazine, 16:1