Fab lab: Difference between revisions

m (using an external editor) |

m (using an external editor) |

||

| Line 11: | Line 11: | ||

The first Fab Lab emerged at MIT under the direction of N. Gershenfeld. It included a laser cutter, a miniature milling machine and jigsaw cutting machine. | The first Fab Lab emerged at MIT under the direction of N. Gershenfeld. It included a laser cutter, a miniature milling machine and jigsaw cutting machine. | ||

The Fab Lab moved also is anchored in ecological thinking. {{Think of RepRap as a China on your desktop}} (Chris di Bona). Materials used are no much polluting and there is no transportation cost. | The Fab Lab moved also is anchored in ecological thinking. {{quotation|Think of RepRap as a China on your desktop}} (Chris di Bona). Materials used are no much polluting and there is no transportation cost. | ||

== History == | == History == | ||

| Line 36: | Line 36: | ||

=== Solid Freeform Fabrication === | === Solid Freeform Fabrication === | ||

{{quotation|Freeform Fabrication is a collection of manufacturing technologies with which parts can be created without the need for part-specific tooling. A computerized model of the part is designed. It is sliced computationally, and layer information is sent to a fabricator that reproduces the layer in a real material}} ([http://utwired.engr.utexas.edu/lff/ Laboratory of Freeform Fabrication], UTexas, retrieved 10: | {{quotation|Freeform Fabrication is a collection of manufacturing technologies with which parts can be created without the need for part-specific tooling. A computerized model of the part is designed. It is sliced computationally, and layer information is sent to a fabricator that reproduces the layer in a real material}} ([http://utwired.engr.utexas.edu/lff/ Laboratory of Freeform Fabrication], UTexas, retrieved 10:40, 24 June 2009 (UTC)). Commercial "low-cost" free form fabricators range between 20'000 and 300'000 $US. | ||

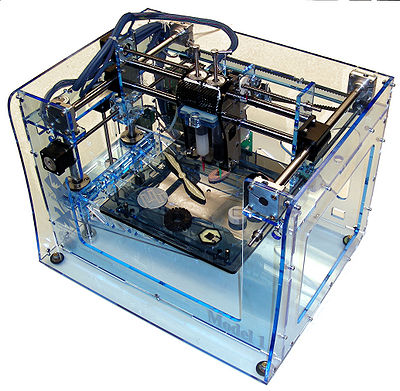

[[image:fab-at-home-fabber.jpg|thumb|400px|right|Fab@Home Fabber model 1, 2007: Source [http://www.fabathome.org/wiki/index.php?title=Image:IMG_0110.jpg fabathome.org]]] | [[image:fab-at-home-fabber.jpg|thumb|400px|right|Fab@Home Fabber model 1, 2007: Source [http://www.fabathome.org/wiki/index.php?title=Image:IMG_0110.jpg fabathome.org]]] | ||

| Line 44: | Line 44: | ||

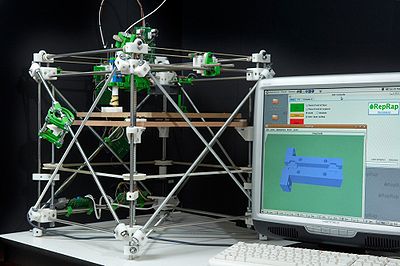

[[image:reprap.jpg|thumb|400px|right|RepRap self-replicating 3D printer]] | [[image:reprap.jpg|thumb|400px|right|RepRap self-replicating 3D printer]] | ||

[http://reprap.org/ RepRap] is another well know project. {{quotation|RepRap is short for Replicating Rapid-prototyper. It is the practical self-copying 3D printer shown on the right - a self-replicating machine. This 3D printer builds the parts up in layers of plastic. This technology already exists, but the cheapest commercial machine would cost you about €30,000. And it isn't even designed so that it can make itself. So what the RepRap team are doing is to develop and to give away the designs for a much cheaper machine with the novel capability of being able to self-copy (material costs are about €500). That way it's accessible to small communities in the developing world as well as individuals in the developed world. Following the principles of the Free Software Movement we are distributing the RepRap machine at no cost to everyone under the GNU General Public Licence. So, if you have a RepRap machine, you can use it to make another and give that one to a friend...}} ([http://reprap.org/bin/view/Main/WebHome What is RepRap?], retrieved 10: | [http://reprap.org/ RepRap] is another well know project. {{quotation|RepRap is short for Replicating Rapid-prototyper. It is the practical self-copying 3D printer shown on the right - a self-replicating machine. This 3D printer builds the parts up in layers of plastic. This technology already exists, but the cheapest commercial machine would cost you about €30,000. And it isn't even designed so that it can make itself. So what the RepRap team are doing is to develop and to give away the designs for a much cheaper machine with the novel capability of being able to self-copy (material costs are about €500). That way it's accessible to small communities in the developing world as well as individuals in the developed world. Following the principles of the Free Software Movement we are distributing the RepRap machine at no cost to everyone under the GNU General Public Licence. So, if you have a RepRap machine, you can use it to make another and give that one to a friend...}} ([http://reprap.org/bin/view/Main/WebHome What is RepRap?], retrieved 10:40, 24 June 2009 (UTC)). | ||

Until recently, fabbers had to be assembled by the end-user using open designs and low-level parts, i.e. many many days of bricolage. However, some fabbers now can be bought commercially as easy kits or fully assembled. E.g. in ''June 2009'', the [http://store02.prostores.com/servlet/kobask8/StoreFront NextFab Store] sold kits for about $3000 and assembled Fab@Homes for about $4000. [http://www.bitsfrombytes.com/ Bits from Byte] sold a [http://www.bitsfrombytes.com/index.php?option=com_content&view=article&id=77&Itemid=100006 ReRap kit] (Version 3 - RapMan) for about £750. | Until recently, fabbers had to be assembled by the end-user using open designs and low-level parts, i.e. many many days of bricolage. However, some fabbers now can be bought commercially as easy kits or fully assembled. E.g. in ''June 2009'', the [http://store02.prostores.com/servlet/kobask8/StoreFront NextFab Store] sold kits for about $3000 and assembled Fab@Homes for about $4000. [http://www.bitsfrombytes.com/ Bits from Byte] sold a [http://www.bitsfrombytes.com/index.php?option=com_content&view=article&id=77&Itemid=100006 ReRap kit] (Version 3 - RapMan) for about £750. | ||

Revision as of 11:40, 24 June 2009

This article or section is currently under construction

In principle, someone is working on it and there should be a better version in a not so distant future.

If you want to modify this page, please discuss it with the person working on it (see the "history")

Introduction

A Fab Lab (fabrication laboratory) is a small-scale workshop with computer controlled tools with the aime to make "almost anything". (Wikipedia).

Fab labs can have different aims, e.g. rapid prototyping or low cost and on-demand manufacturing from "open source designs". Both purposing would include an idea of empowering individuals to create devices that are adapted to specific needs. The Fab@Home project emphasizes freedom of design and innovation of a Solid Freeform Fabrication system:

The first Fab Lab emerged at MIT under the direction of N. Gershenfeld. It included a laser cutter, a miniature milling machine and jigsaw cutting machine.

The Fab Lab moved also is anchored in ecological thinking. “Think of RepRap as a China on your desktop” (Chris di Bona). Materials used are no much polluting and there is no transportation cost.

History

- 1940's

- Birth of numerical control, i.e. machine tools controlled by code.

- mid 1950's

- Birth of special purpose programming languages for computer numerical controlled (CNC) machine tools.

- end 1950's - mid 1960's

- Birth of interfaces of Computer-Aided Design (CAD) with CNC.

- 1970

- Dr. Mohamed Hashish created a technique to add abrasives to the water jet cutter

- 2005

- Neil Gershenfeld's et al. MIT class 863.04 - how to make (almost) anything.

- 2007

- Neil Gershenfeld and Joe Jacobson MIT class How To Make Something That Makes (almost) Anything.

Technology

Solid Freeform Fabrication

“Freeform Fabrication is a collection of manufacturing technologies with which parts can be created without the need for part-specific tooling. A computerized model of the part is designed. It is sliced computationally, and layer information is sent to a fabricator that reproduces the layer in a real material” (Laboratory of Freeform Fabrication, UTexas, retrieved 10:40, 24 June 2009 (UTC)). Commercial "low-cost" free form fabricators range between 20'000 and 300'000 $US.

Low End Solid Freeform Fabrication tools, also called rapid prototype machines are usually a kind of 3D printers. There exist various kinds.

Very low-cost non-proprietry 3D printers are ofter called Fabbers. The Fab@Home project (retrieved June 2009) “is a project dedicated to making and using fabbers - machines that can make almost anything, right on your desktop. [...] Fabbers (a.k.a. 3D printers or rapid prototyping machines) are a relatively new form of manufacturing that builds 3D objects by carefully depositing materials drop by drop, layer by layer. With the right set of materials and a geometric blueprint, you can fabricate complex objects that would normally take special resources, tools and skills if produced using conventional manufacturing techniques. A fabber can allow you to explore new designs, email physical objects to other fabber owners, and most importantly - set your ideas free. Just as MP3s, iPods and the Internet have freed musical talent, we hope that blueprints and fabbers will democratize innovation.”

RepRap is another well know project. “RepRap is short for Replicating Rapid-prototyper. It is the practical self-copying 3D printer shown on the right - a self-replicating machine. This 3D printer builds the parts up in layers of plastic. This technology already exists, but the cheapest commercial machine would cost you about €30,000. And it isn't even designed so that it can make itself. So what the RepRap team are doing is to develop and to give away the designs for a much cheaper machine with the novel capability of being able to self-copy (material costs are about €500). That way it's accessible to small communities in the developing world as well as individuals in the developed world. Following the principles of the Free Software Movement we are distributing the RepRap machine at no cost to everyone under the GNU General Public Licence. So, if you have a RepRap machine, you can use it to make another and give that one to a friend...” (What is RepRap?, retrieved 10:40, 24 June 2009 (UTC)).

Until recently, fabbers had to be assembled by the end-user using open designs and low-level parts, i.e. many many days of bricolage. However, some fabbers now can be bought commercially as easy kits or fully assembled. E.g. in June 2009, the NextFab Store sold kits for about $3000 and assembled Fab@Homes for about $4000. Bits from Byte sold a ReRap kit (Version 3 - RapMan) for about £750.

Cutters

- Laser cutters

- Plasma cutters

- Water jet cutter

- “A water jet cutter is a tool capable of slicing into metal or other materials using a jet of water at high velocity and pressure, or a mixture of water and an abrasive substance. The process is essentially the same as water erosion found in nature but greatly accelerated and concentrated. It is often used during fabrication or manufacture of parts for machinery and other devices” (Wikipedia, retrieved 21:22, 23 June 2009 (UTC).)

According to Wikipedia, water jets can cut with a with of about 1mm and can cut materials such as rubber, foam, plastics, composites, stone, glas, tile, metals, food, paper and much more. Also, water jets can cut material without much harming or changing the materials' structures since there is no heat. I also can be considered a green technology, since it doesn't produce harmful waste. Water and abrasives can be recycled.

CNC mills

A milling machine (fr. "fraiseuse") is a machine tool used for the shaping of metal and other solid materials. It uses rotating cutters to cut stuff from a workpiece. In more sophisticated milling machines, both the cutters and the workpiece can be rotated in three axis.

Links

Fab Labs and rapid prototyping

- FabCentral, The Center for Bits and Atoms, MIT.

- Fab Lab FAQ, MIT. (includes further pointers).

- Desktop manufacturing - Helping poor-world inventors, The Economist, Mar 23 2005.

Hardware hacking / modified objects

Numerical control

- Numerical control (Wikipedia)

Hardware

- 3D printers

- Fab@Home, is a project dedicated to making and using fabbers - machines that can make almost anything, right on your desktop. This website provides everything you need to know in order to build or buy your own simple fabber, and to use it to print three dimensional object. Hardware designs and software on this website are open source.

- Bits from Bytes. Sells RepRap kits.

- Three dimensional printing Laboratory (MIT,last update 2000)

- 3D Printer System Manufacturers - Systems for Less Than US$20,000 (parts for self-assembly can be as low as $600)

- Overviews

- [http://home.att.net/~castleisland/rp_int1.htm The Most Important Commercial

Rapid Prototyping Technologies at a Glance]

- Water jets

- CNC mills

New technology

- NewScientist (tech section)

Bibliography

- Burns M., (1995) The Freedom to Create, in Technology Management, Volume 1, Number 4 http://www.ennex.com/~fabbers/publish/199407-MB-FreedomCreate.asp

- Gershenfeld N., (2005) FAB: The Coming Revolution on Your Desktop – From Personal Computers to Personal Fabrication, Basic Books.

- Editors' Review (2005). Desktop Factories - FAB The Coming Revolution on Your Desktop -- from Personal Computers to Personal Fabrication By Neil Gershenfeld, Basic Books, Business Week, May 2 2005.

- Gershenfeld N. Think Globally, fabricate locally, PrincipalVoices.com. PDF (reprint)

- Jenweill, Mark, Fab Labs unshackle imaginations, USA Today, 11/6/2005.

- Lipson H. (2005) "Homemade: The future of Functional Rapid Prototyping", IEEE Spectrum, feature article, May 2005, pp. 24-31 http://www.mae.cornell.edu/ccsl/papers/Spectrum05_Lipson.pdf

- Bowyer A., RepRap: The Replicating Rapid-Prototyper, http://reprap.org